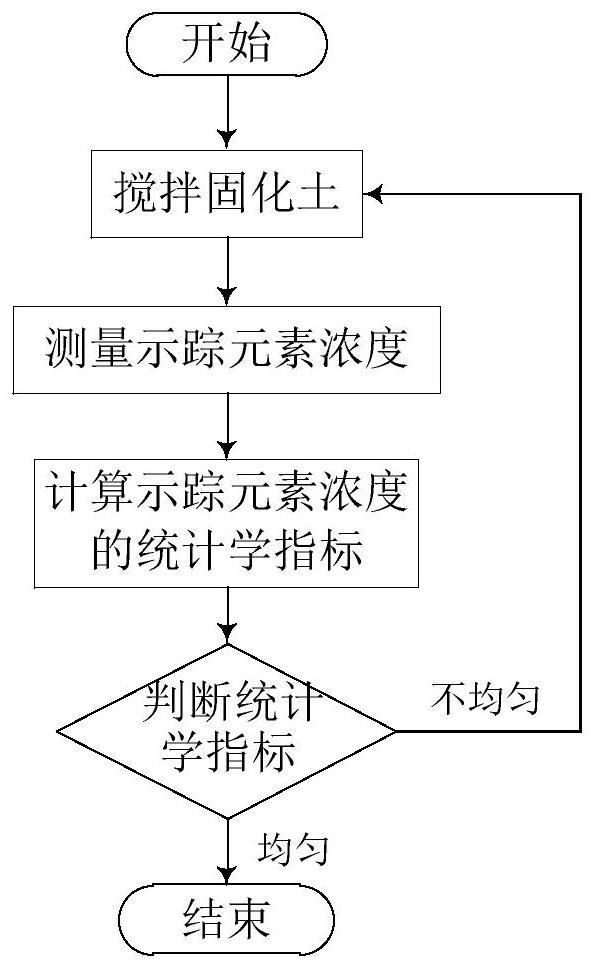

Method for rapidly detecting mixing uniformity of cement-solidified soil

A cement solidification and uniformity technology, applied in the field of construction engineering, can solve the problems of waste of human and material resources, discontinuous pile body, poor mixing uniformity, etc., to achieve strong operability, improve construction quality and work efficiency, improve construction quality and The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The method for testing the uniformity of cement-solidified soil will be further described in detail below. The following implementation steps are only used to describe the content of the present invention more clearly and are not intended to limit the scope of the present invention.

[0033] Quickly detect the construction mixing quality of cement solidified sludge at a construction site:

[0034] 1) According to the expected cement content of 10%, use the local mixing equipment to slowly lift and mix and spray the curing agent to mix the cement and silt soil, stirring for 2 minutes at each mixing point.

[0035] 2) After the stirring is completed, carry out leveling and maintenance, and divide five 10m×10m×1m blocks in the curing area. Use a handheld X-ray fluorescence spectrometer to measure the calcium concentration of 5 blocks respectively, 1m 3 Take 15 test points.

[0036] 3) Calculate the coefficient of variation of each block. The test results are shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com