High-specific-volume and high-strength medium-high-voltage corrosion electrode foil and preparation method and application thereof

A corrosion electrode, medium and high voltage technology, applied in the direction of circuits, capacitors, electrical components, etc., can solve the problem of inability to balance specific volume and bending performance, to ensure uniform pore diameter and pore density, uniform corrosion, and reduce the probability of occurrence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

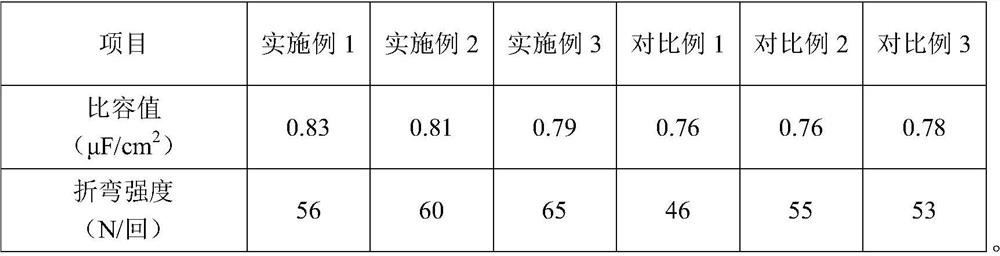

Examples

Embodiment 1

[0042] This embodiment provides a method for preparing a medium-high voltage corroded electrode foil with high specific volume and high strength, which includes the following steps:

[0043] (1) Pretreatment: Put the aluminum foil in a sodium hydroxide solution with a concentration of 0.5% (mass concentration), take it out after dipping, and pickle it with the overflow waste liquid (containing hydrochloric acid) of the primary tank.

[0044] (2) First-level DC porosity corrosion: Put the pretreated aluminum foil into a mixture of sulfuric acid with a concentration of 30% (mass concentration) and hydrochloric acid with a concentration of 0.8% (mass concentration) (at a temperature of 70°C) Level DC porosity corrosion, the current density is 0.3A / cm 2 , the electricity is 40C / cm2 , the time is 65 seconds.

[0045] (3) Intermediate treatment: the above-mentioned aluminum foil corroded by first-level direct current electrolytic porosity was placed in a phosphoric acid solution wi...

Embodiment 2

[0051] This embodiment provides a method for preparing a medium-high voltage corroded electrode foil with high specific volume and high strength, which includes the following steps:

[0052] (1) Pretreatment: Put the aluminum foil in a sodium hydroxide solution with a concentration of 0.5% (mass concentration), take it out after dipping, and pickle it with the overflow waste liquid (containing hydrochloric acid) of the primary tank.

[0053] (2) First-level DC porosity corrosion: Put the pretreated aluminum foil into a mixture of sulfuric acid with a concentration of 20% (mass concentration) and hydrochloric acid with a concentration of 0.5% (mass concentration) (at a temperature of 65°C) Level DC porosity corrosion, the current density is 0.34A / cm 2 , the power is 41.6C / cm 2 , the time is 45 seconds.

[0054] (3) Intermediate treatment: the above-mentioned aluminum foil corroded by primary direct current electrolytic porosity was placed in a phosphoric acid solution with a ...

Embodiment 3

[0060] This embodiment provides a method for preparing a medium-high voltage corroded electrode foil with high specific volume and high strength, which includes the following steps:

[0061] (1) Pretreatment: Put the aluminum foil in a sodium hydroxide solution with a concentration of 0.5% (mass concentration), take it out after dipping, and pickle it with the overflow waste liquid (containing hydrochloric acid) of the primary tank.

[0062] (2) First-level DC porosity corrosion: Put the pretreated aluminum foil into a mixture of sulfuric acid with a concentration of 40% (mass concentration) and hydrochloric acid with a concentration of 1% (mass concentration) (at a temperature of 75°C) Level DC porosity corrosion, the current density is 0.0285A / cm 2 , the power is 39.4C / cm 2 , the time is 90 seconds.

[0063] (3) Intermediate treatment: place the above-mentioned aluminum foil corroded by primary direct current electrolytic porosity in a phosphoric acid solution with a conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com