Closed cavity for injecting liquid into button cell

A button battery and closed cavity technology, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as low efficiency, affecting battery liquid injection efficiency, and inability to perform liquid injection and cleaning at the same time, so as to avoid corrosion damage , Improve the effect of injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

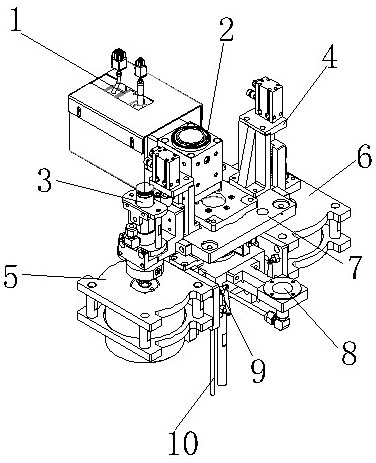

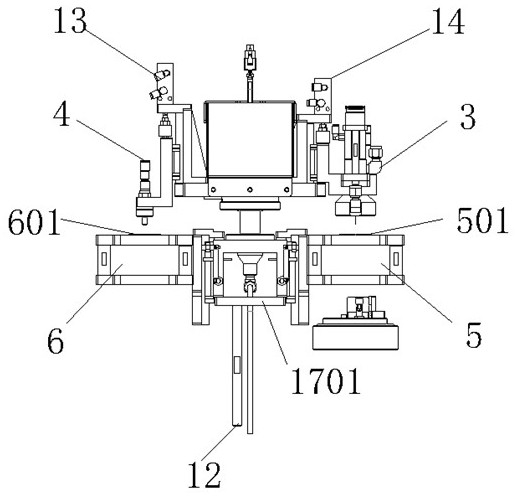

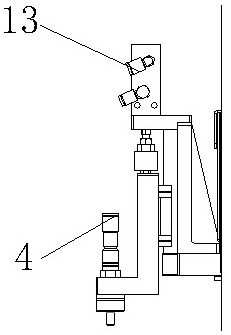

[0026] Example: see Figure 1-8 , a sealed chamber for button battery liquid injection, which includes a servo motor 1, a hollow rotary platform 2, a liquid injection valve assembly 3, a cleaning check valve 4, a liquid injection chamber 5 and a cleaning chamber 6, and one side of the servo motor 1 Connected with a hollow rotary platform 2, the bottom of the hollow rotary platform 2 is fixedly provided with a fixed platform 7, and one side of the fixed platform 7 is fixedly provided with a liquid injection valve assembly 3 and a cleaning check valve 4, and the hollow rotary platform 2 is connected with a rotating shaft 17, on which a rotating fixed frame 1701 is fixed, and the two sides of the rotating fixed frame 1701 are movable up and down and provided with the liquid injection chamber 5 and the cleaning chamber 6, the liquid injection A liquid injection receiving platform 20 is movable below the cavity 5 .

[0027] Among them, the servo motor 1 provides the rotation power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com