Cigar vacuum microwave drying process

A vacuum microwave drying and cigar technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems that the drying method of flue-cured tobacco cannot be directly applied to cigar drying, and there is a risk of insects, so as to avoid the moisture content being too large or too small, Faster drying, targeted results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

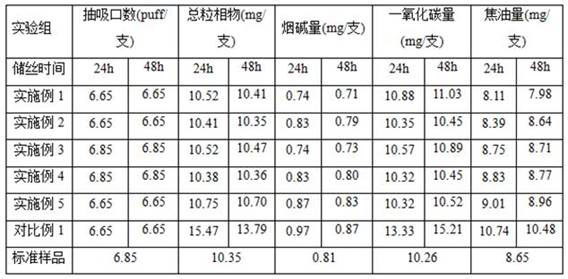

Examples

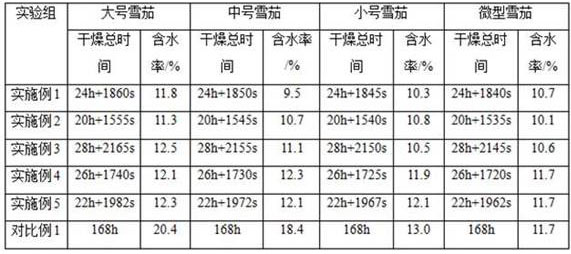

Embodiment 1

[0026] A cigar vacuum microwave drying process, comprising the following steps:

[0027] (1) Cigars are divided into large cigars with a weight greater than or equal to 6g, medium cigars with a weight of less than 6g and greater than or equal to 3g, small cigars with a weight of less than 3g and greater than or equal to 1.2g, and miniature cigars with a weight of less than 1.2g.

[0028] (2) Place the cigars in different drying devices according to their categories. In each drying device, the cigars are placed in a single row and not stacked in multiple rows.

[0029] (3) Adjust the temperature in all drying devices to -20°C and the vacuum degree to 0.06MPa. After drying cigars of various quality categories for 30 minutes, turn on the microwave source and continue drying at a microwave power of 6KW. When microwave drying, the drying time is 60s for large cigars, 50s for medium cigars, 45s for small cigars and 40s for micro cigars.

[0030] (4) Raise the temperature of all dry...

Embodiment 2

[0035] A cigar vacuum microwave drying process, comprising the following steps:

[0036] (1) Cigars are divided into large cigars with a weight greater than or equal to 6g, medium cigars with a weight of less than 6g and greater than or equal to 3g, small cigars with a weight of less than 3g and greater than or equal to 1.2g, and miniature cigars with a weight of less than 1.2g.

[0037] (2) Place the cigars in different drying devices according to their categories. In each drying device, the cigars are placed in a single row and not stacked in multiple rows.

[0038] (3) Adjust the temperature in all drying devices to -22°C and the vacuum degree to 0.04MPa. After drying cigars of various quality categories for 25 minutes, turn on the microwave source and continue drying at a microwave power of 5KW. Under the microwave, the jumbo cigars dry in 55 seconds, the medium cigars in 45 seconds, the petites in 40 seconds, and the micro cigars in 35 seconds. At the same time, when dry...

Embodiment 3

[0044] A cigar vacuum microwave drying process, comprising the following steps:

[0045] (1) Cigars are divided into large cigars with a weight greater than or equal to 6g, medium cigars with a weight of less than 6g and greater than or equal to 3g, small cigars with a weight of less than 3g and greater than or equal to 1.2g, and miniature cigars with a weight of less than 1.2g.

[0046] (2) Place the cigars in different drying devices according to their categories. In each drying device, the cigars are placed in a single row and not stacked in multiple rows.

[0047](3) Adjust the temperature in all drying devices to -18°C and the vacuum degree to 0.08MPa. After drying cigars of various quality categories for 35 minutes, turn on the microwave source. Under the microwave, the jumbo cigars dried in 65s, the medium cigars in 55s, the petites in 50s and the petit cigars in 45s.

[0048] Among them, the cigars were first dried with a microwave power of 8KW for 10s, then paused in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com