A software grasping device and method based on artificial muscle drive

A technology of artificial muscles and grasping devices, which is applied in the field of flexible robots, can solve problems such as the inability to realize miniaturization of the overall structure, difficulty in miniaturization and light weight, and unsuitability for large-scale applications, so as to reduce the overall price cost and time cost, The overall structure is highly integrated and the appearance is neat and tidy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

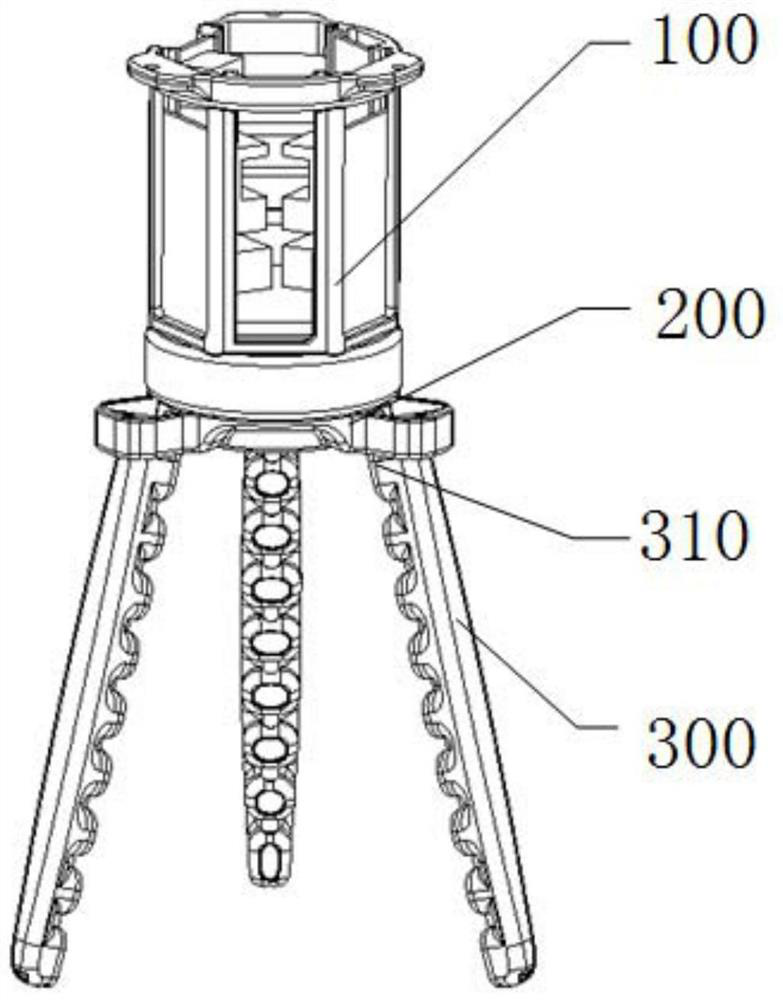

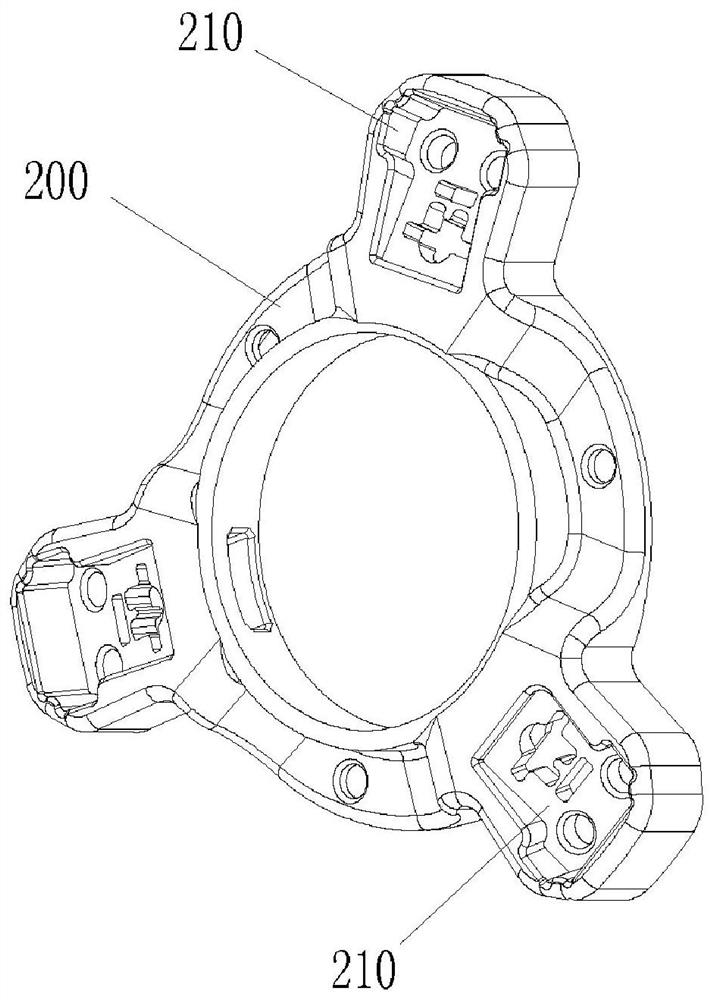

[0052] A soft grasping device driven by artificial muscles, such as figure 1 As shown in -6, it includes an arm 100, a palm 200 and three soft fingers 300. The palm 200 is set on the arm 100, and the three soft fingers 300 are set on the palm 200 in an evenly distributed manner.

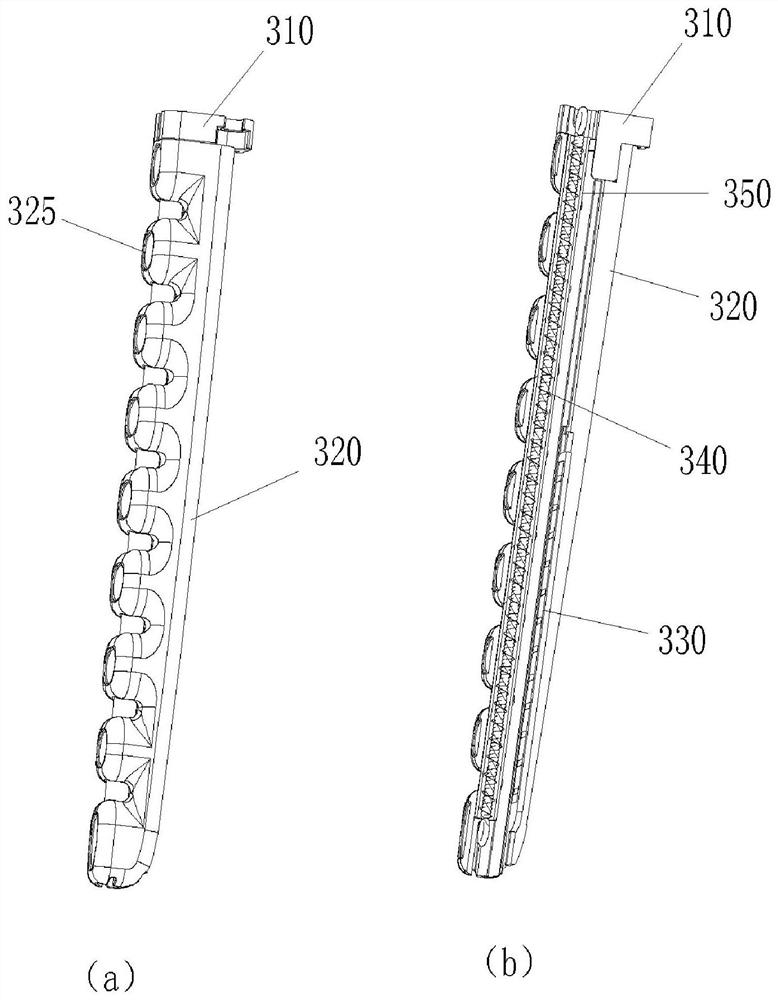

[0053] The soft finger 300 includes an end cap 310, a finger body 320, a bending sensor 330, an artificial muscle 340, and a high-temperature-resistant tube 350. The finger body 320 is connected to the palm 200 through the end cap 310. The finger body 320 is equipped with The first slot 321, the second slot 322, the third slot 323, such as Figure 4 , 5 As shown, among them, Figure 5 a is a longitudinal sectional view of the finger body 320, Figure 5 b is a transverse cross-sectional view of the finger body 320. The artificial muscle 340 is set in the first slot 321 after being set in the high temperature resistant tube 350 and is located on the grasping front of the finger body 320. The bending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com