Plastic bottle cap orientation screening device

A screening device and bottle cap technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of high cost, complex structure, and the need to connect air sources, etc., to achieve rapid directional screening, high screening accuracy, Good running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

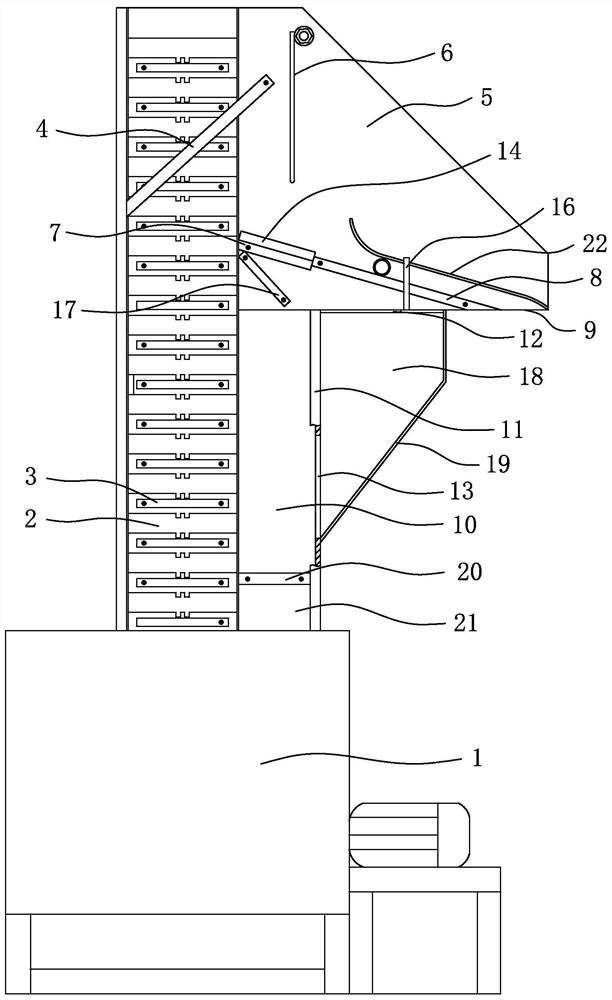

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

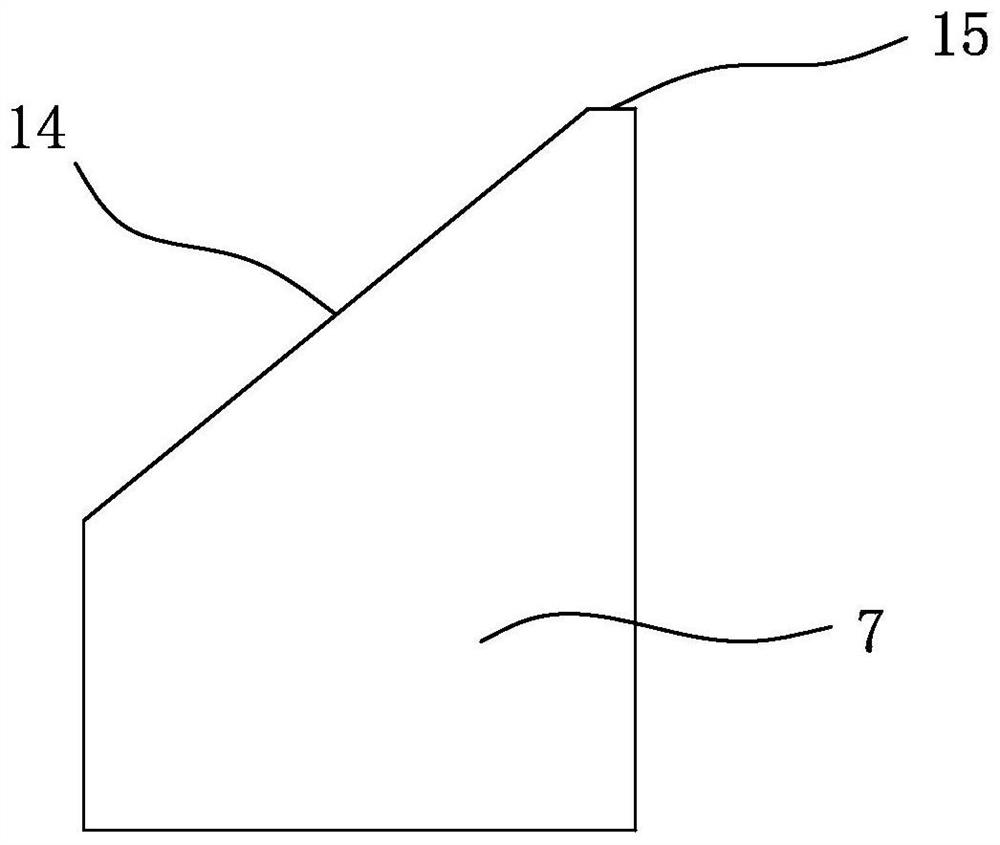

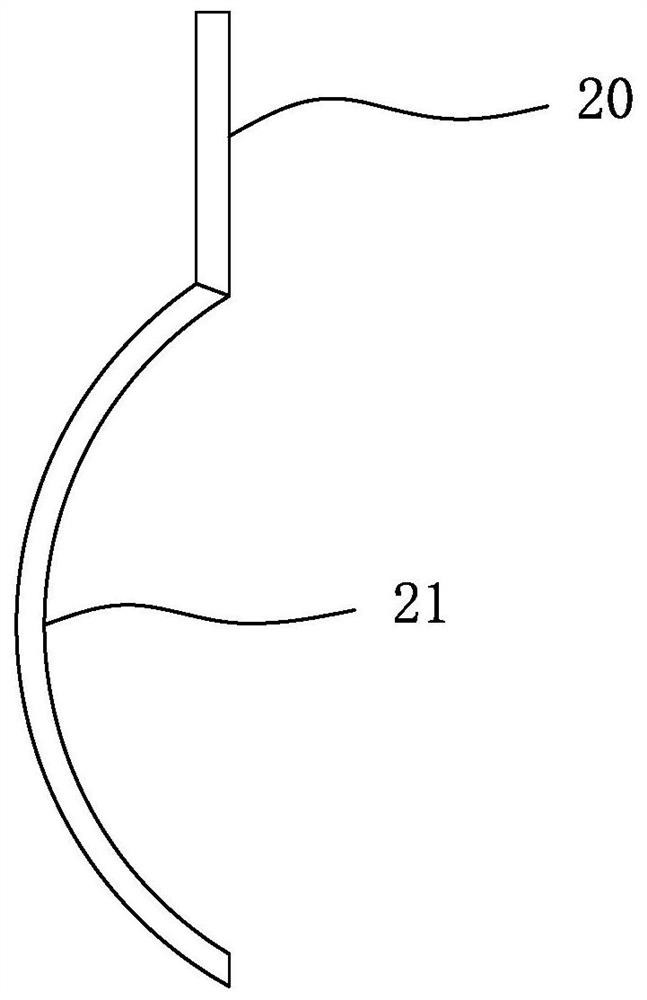

[0021] Such as figure 1 The shown plastic bottle cap is facing the screening device, which includes a hopper 1 and a chain conveyor belt 2. The bottle cap in the hopper is lifted upwards, and an inclined push-off plate 4 is fixed above the upper part of the chain-plate conveyor belt. The distance between the push-off plate and the chain-plate conveyor belt is smaller than the thickness of the bottle cap. Plate 5, a longitudinal bar 6 is arranged on the mounting plate near the higher end of the push-off plate, and a first screening track 7 is fixed on the mounting plate below the longitudinal bar, and the first screening track is a strip plate Shaped structure, the outside of the first screening track is provided with a blanking guide slope 14, and the horizontal plane of the top surface of the first screening track forms a bottle cap supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com