Preparation method of high-temperature, high-frequency and low-loss ferrite material

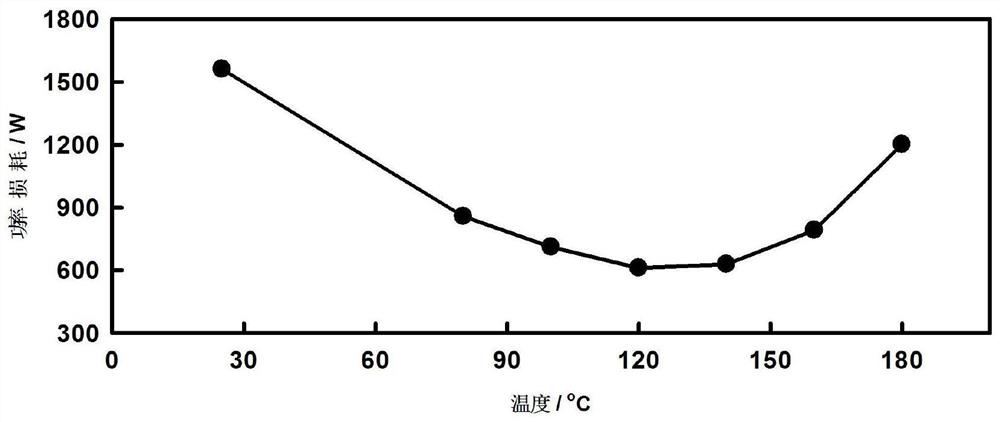

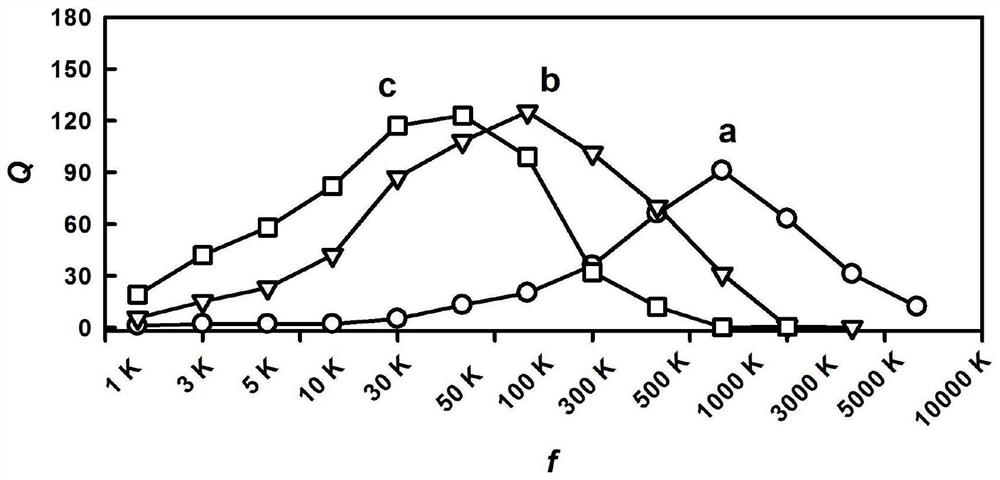

A ferrite material and low-loss technology, applied in the field of ferrite material preparation, can solve the problem of low power loss and achieve the effect of low power loss, low power loss, and reduced power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a high-temperature, high-frequency, low-loss ferrite material, comprising the following preparation steps:

[0029] 1), using a formula of 52-58 mol% ferric oxide, 9-13 mol% zinc oxide, 0.5-5 mol% nickel oxide, and 31-38 mol% manganese carbonate to mix and grind evenly to form grinding powder;

[0030] 2), pre-calcining the ground powder obtained in step 1) at a temperature of 950-1050° C. to form a fired powder;

[0031] 3), add the following additives to the fired powder obtained in step 2) according to the mass ratio: tin dioxide, titanium dioxide and vanadium pentoxide, and grind again, so that the particle size of the ground powder reaches the primary level of submicron Powder;

[0032] 4), adding an organic binder to the primary powder obtained in step 3), and granulating the primary powder into a granular blank;

[0033] 5) The granular blank obtained in step 4) is placed in a sintering furnace for high-temperature sintering for several h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com