Aluminum electrolysis cell side furnace wall repairing system

An aluminum electrolytic cell and repair system technology, applied in the field of cooling devices, can solve problems such as side silicon carbonitride brick corrosion, high temperature of side heat dissipation windows, and thin side furnace sides, etc., to ensure safety, The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

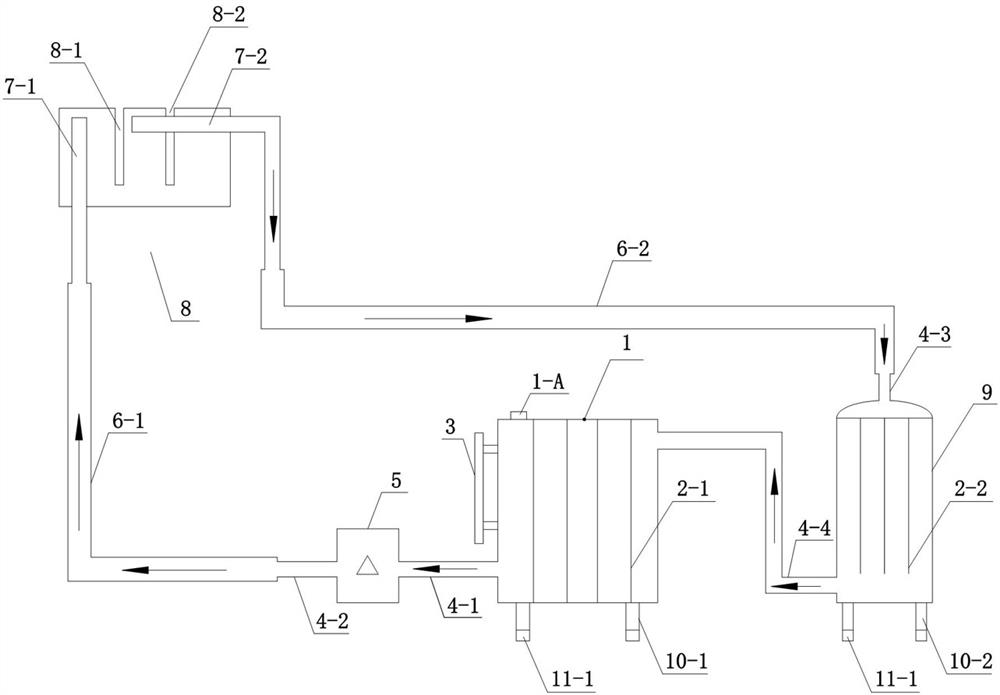

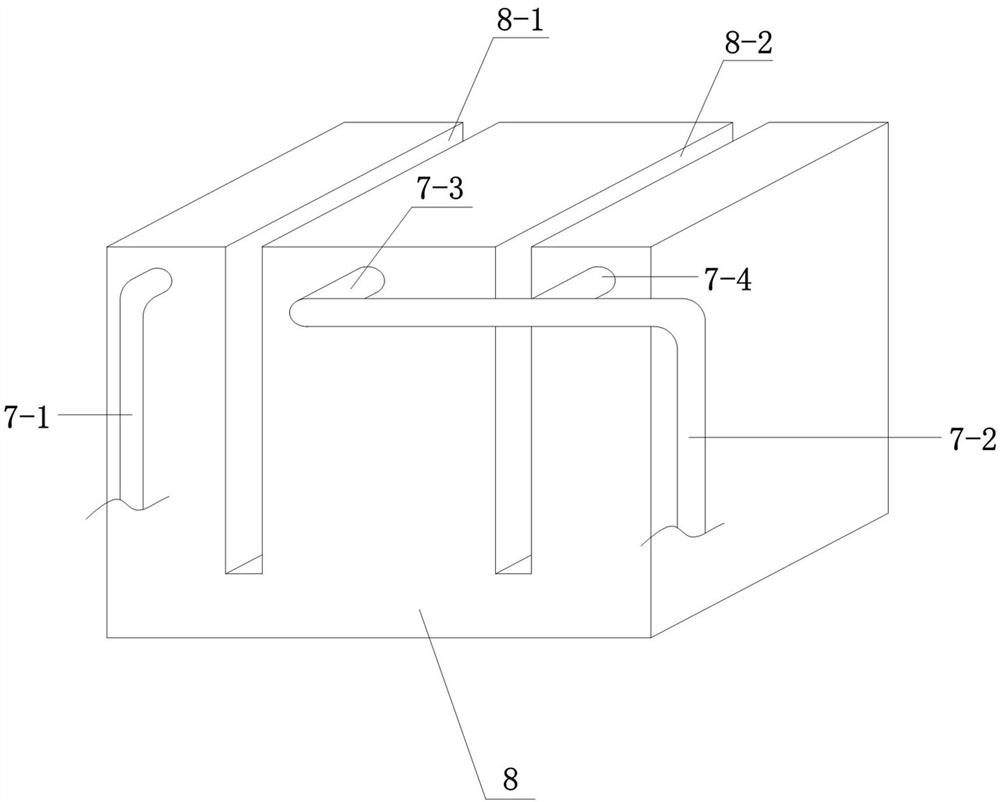

[0020] The following structural drawings further explain and illustrate the present invention:

[0021] see Figure 1-Figure 2 , a side furnace side repair system for an aluminum electrolytic cell, including a water tank 8, a first water tank connecting pipe 7-1 at a position near the top on the left side of the front of the water tank 8, and a first water tank connecting pipe 7-1 at a position near the top on the right side of the front of the water tank 8 There is a second water tank connecting pipe 7-2, and the second water tank connecting pipe 7-2 is connected with the third pipe fitting 4-3 through the second insulating hose 6-2, and the third pipe fitting 4-3 is connected with the top of the resin filter 9 The inlet ends of the resin filter 9 are connected together, the left side of the resin filter 9 is connected with the right side of the pure water tank 1 through the fourth pipe fitting 4-4, and the left side of the pure water tank 1 is connected with the pipeline wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com