Tip timing measurement device and method based on optical fiber bundle probe

A technology of blade tip timing and measuring device, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of unsolved blade tip clearance fluctuation, blade tip timing error, large blade tip timing error, etc. , to solve the tip timing error, reduce the tip timing error, and improve the tip timing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

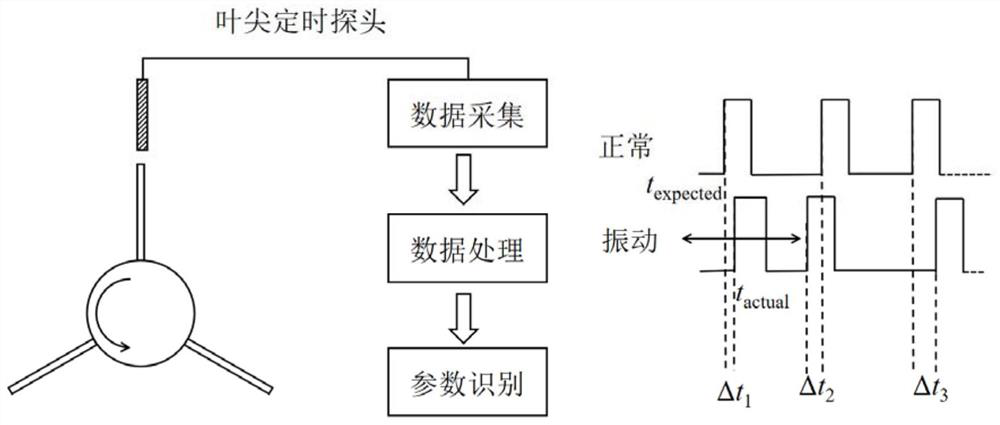

[0021] For the common blade tip timing system, when the blade sweeps the blade tip timing probe during the rotation process, the blade tip timing probe will receive a blade tip timing signal pulse. According to the blade tip timing signal pulse, each The time it takes for a blade to turn to the probe. And when the blade is in the vibrating state, the time t for the blade tip to pass the probe every time it rotates actual will be different, by analyzing the arrival time t of the received blade tip timing signal pulse actual and expected tip arrival time t expected The difference between Δt i The change of the blade can be monitored, such as figure 1 As shown, in this way, the real-time detection of the health status of the blade can be realized.

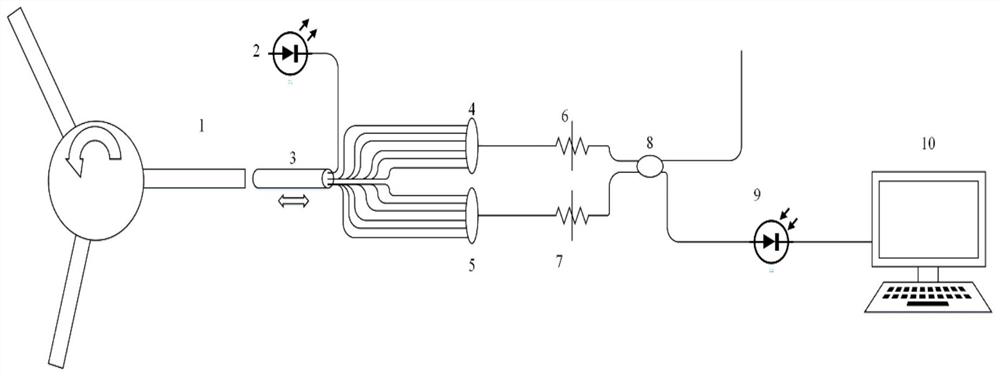

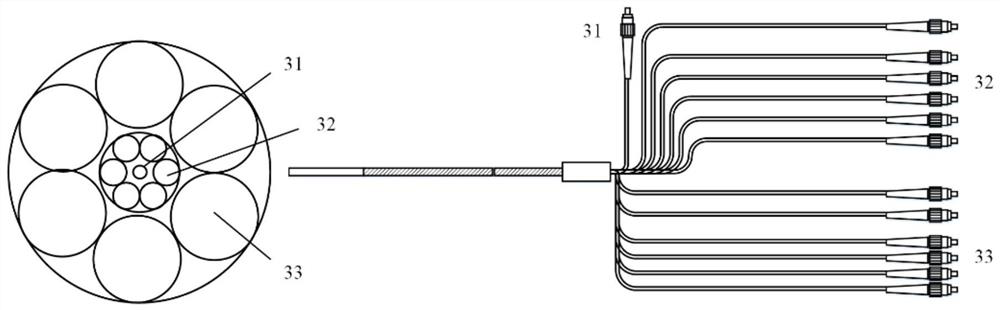

[0022] When the fiber optic bundle probe is used as the blade tip timing probe, the blade t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com