Multifunctional tea leaf processor

A processor and multi-functional technology, applied in the field of multi-functional tea processing machines, can solve the problems of inability to precisely control the moisture regain process, uneven fermentation, and degraded tea quality, achieve a high degree of automation, improve fermentation quality, and promote catechins The effect of conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

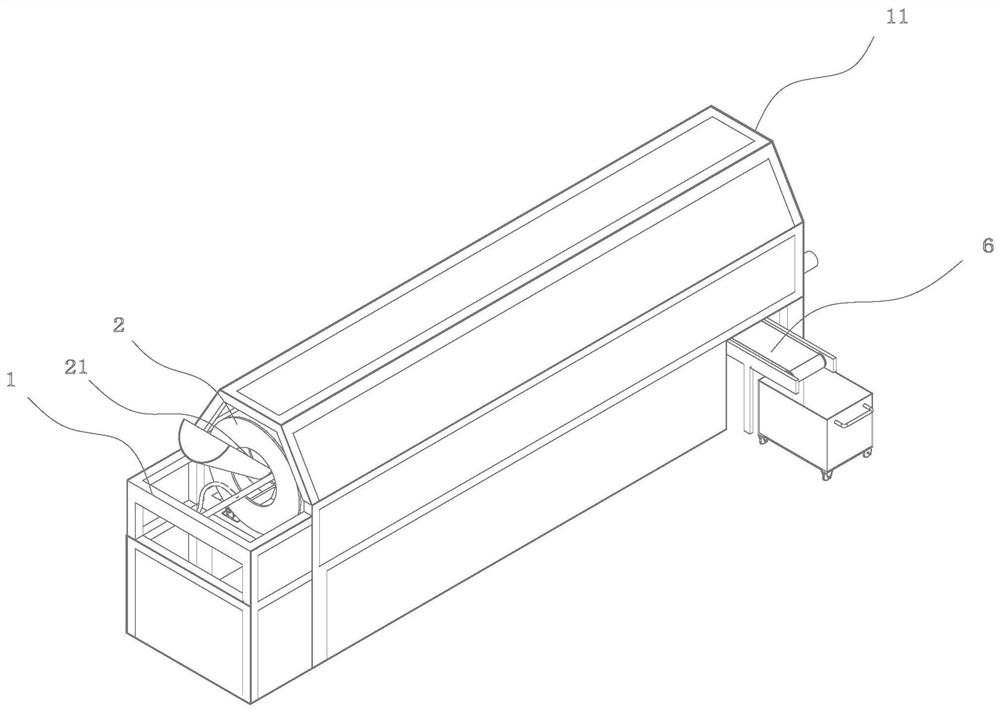

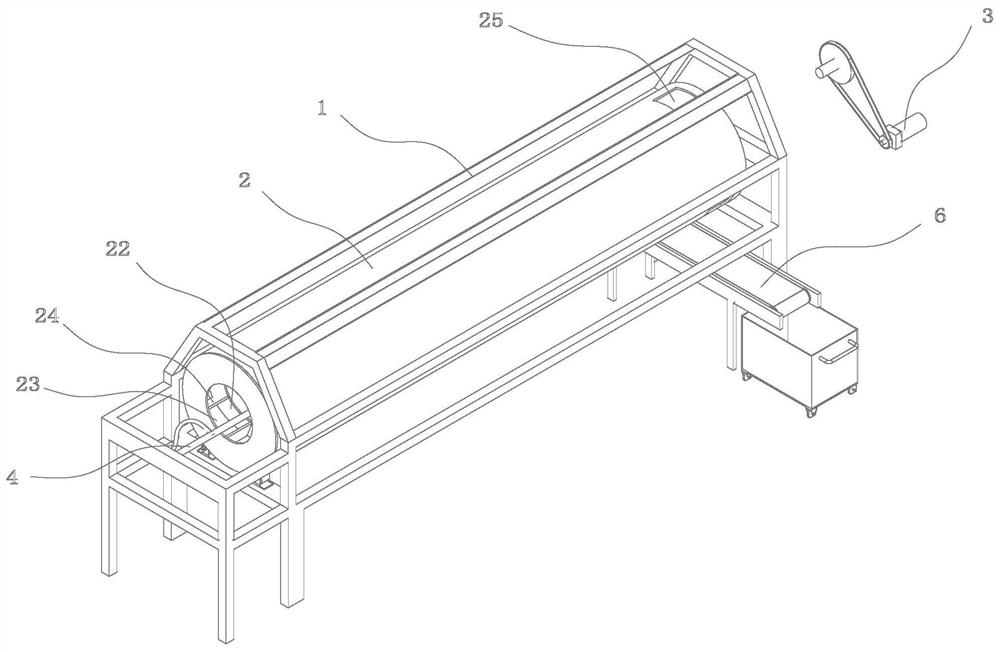

[0024] Embodiment 1: the multi-functional tea processing machine of the present embodiment 1 is used for the green tea processing technology to rejuvenate leaves or the fermentation of black tea processing technology, such as figure 1 and figure 2 As shown, the processing machine includes a frame 1, a drum 2 placed on the frame, a drum driving motor 3, an air supply device and a controller, and the drum driving motor drives the drum to rotate, as Figure 4 As shown, the front end of the drum is designed with a feed port 21, the feed port is located in the center of the front face of the drum, and the rear end of the drum is designed with a discharge port, which includes three square openings evenly distributed on the outer peripheral surface of the rear part of the drum. 25. A tea delivery device 6 is designed below the opening at the rear of the drum, and the tea delivery device corresponds to the above opening; a plurality of spiral guide vane plates 22 are designed on the ...

Embodiment 2

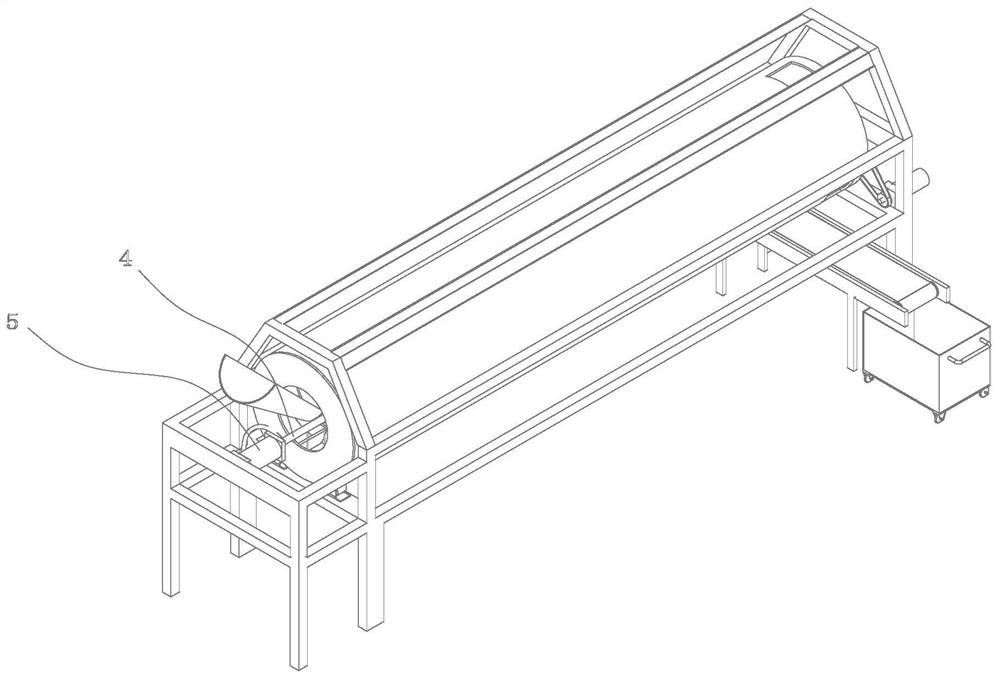

[0027] Embodiment 2: the multifunctional tea processing machine of the present embodiment 2 is used for the green tea processing technology to rejuvenate leaves or the fermentation of black tea processing technology, such as image 3As shown, the front part of the frame is fixed with a rotating cylinder 5, and the above-mentioned air supply pipe is located on the central axis of the drum. The head of the rotating cylinder is fixedly connected with the front end of the air supply pipe and drives the air supply pipe to rotate. And suspended in the air, the air supply pipe is provided with a plurality of elastic struts 41 perpendicular to the axis of the air supply pipe, the front ends of the elastic struts are inserted downwards in the tea layer in the above-mentioned tea delivery trough, and the elastic struts swing left and right according to the process requirements , loosen the static tea layer accumulated in the space of the tea delivery trough, fully ensure the contact betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com