Inbound piece logistics distribution method and sorting system

A sorting system and logistics distribution technology, applied in the field of logistics, can solve the problems of high cost, large floor area, and expensive rent of the floor space, and achieve the effect of saving rental costs, labor costs, and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

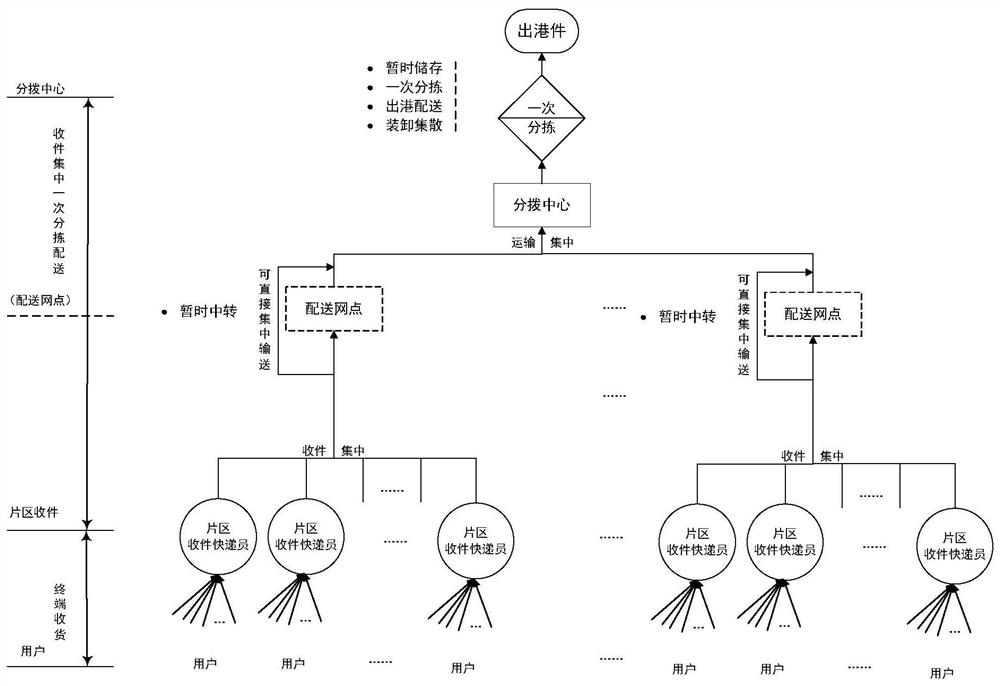

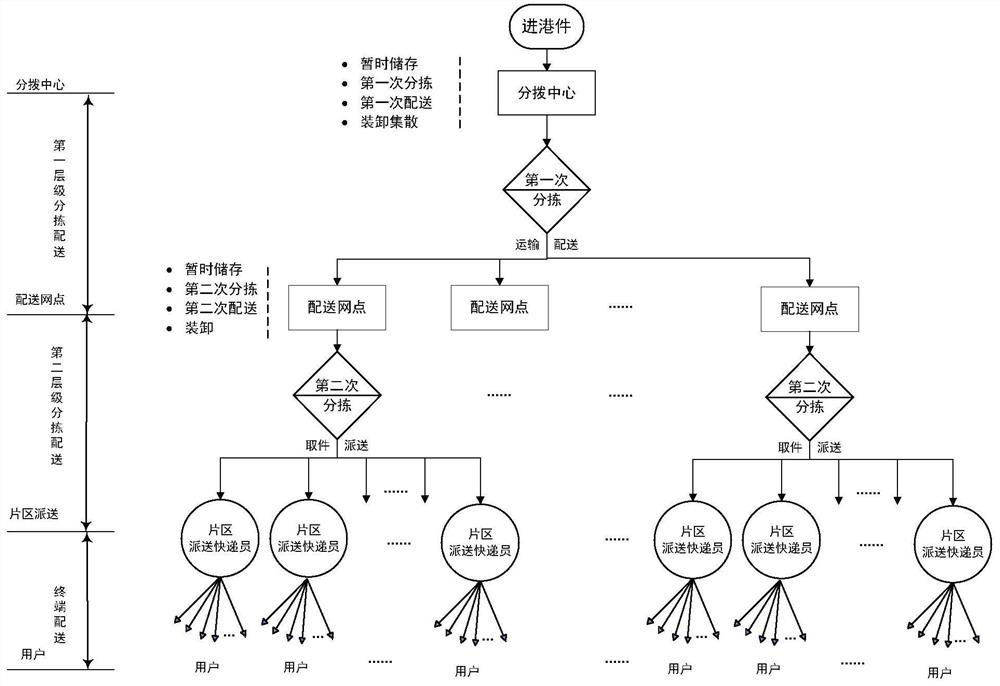

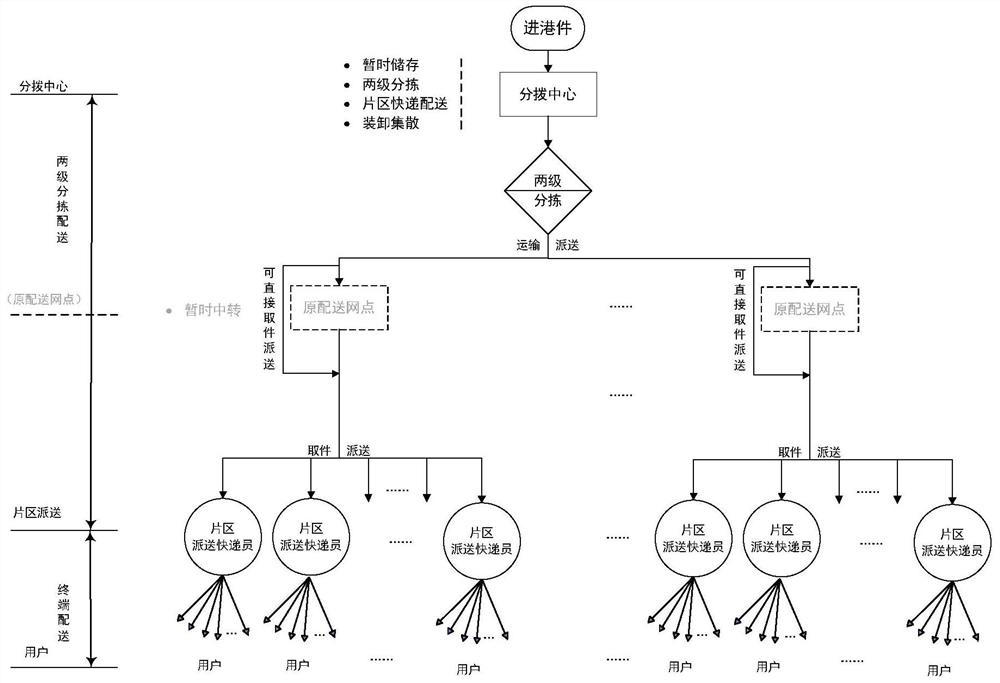

[0027] The existing inbound logistics distribution system adopts a distribution center-distribution network hierarchical distribution network system. At the distribution center level, there are two sorting and distribution methods. One is manual sorting. The number of inbound pieces is huge, and manual sorting is laborious and laborious. Therefore, at the distribution center level, smart sorting machines or sorting robots are usually used to sort devices, and at the distribution network level, two types of sorting are usually used. One is manual sorting, and the other is sorting using intelligent sorting machines or sorting robots. Since the distribution outlets are usually located in urban areas, counties, and town centers, the number of them is large, and the rent of the occupied area is expensive. Large investment, such as the use of intelligent sorting machines or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com