Overhead thermal control system of new energy passenger car

A thermal control system and new energy technology, applied in electric vehicles, vehicle energy storage, vehicle components, etc., can solve problems such as high cost, increased vehicle weight, energy waste, etc., and achieve easy maintenance, guaranteed reliability, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

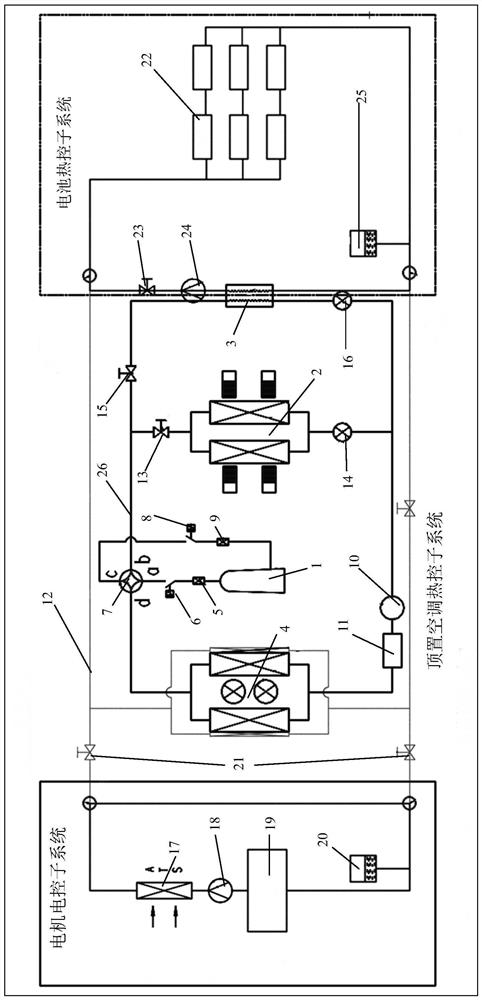

[0025] Such as figure 1 Shown is the overall system structure diagram of the present invention, the thermal control system includes overhead air conditioner thermal control subsystems connected to each other, the connecting pipes in the overhead air conditioner thermal control subsystem adopt refrigerant pipeline 26, battery thermal control subsystem and The motor electronic control subsystem and the thermal control subsystem of the overhead air conditioner include a compressor 1, an air conditioner evaporator 2, a plate heat exchanger 3 and an air conditioner condenser 4, and the compressor 1 passes through the pressure relief valve 5 and the high pressure switch 6 in sequence The port a of the one-way valve 7 is connected, the port c of the four-way valve 7 passes through the low-pressure switch 8 and the gas-liquid separator 9 in turn through another circuit and is connected to the compressor 1, and the port b of the four-way valve 7 passes through the air conditioner evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com