High-carbon bearing steel preparation method

A high-carbon bearing and alloy powder technology, which is applied in the field of bearing steel preparation, can solve the problems of bearing wear resistance, poor dimensional temperature resistance, and poor bearing tempering resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

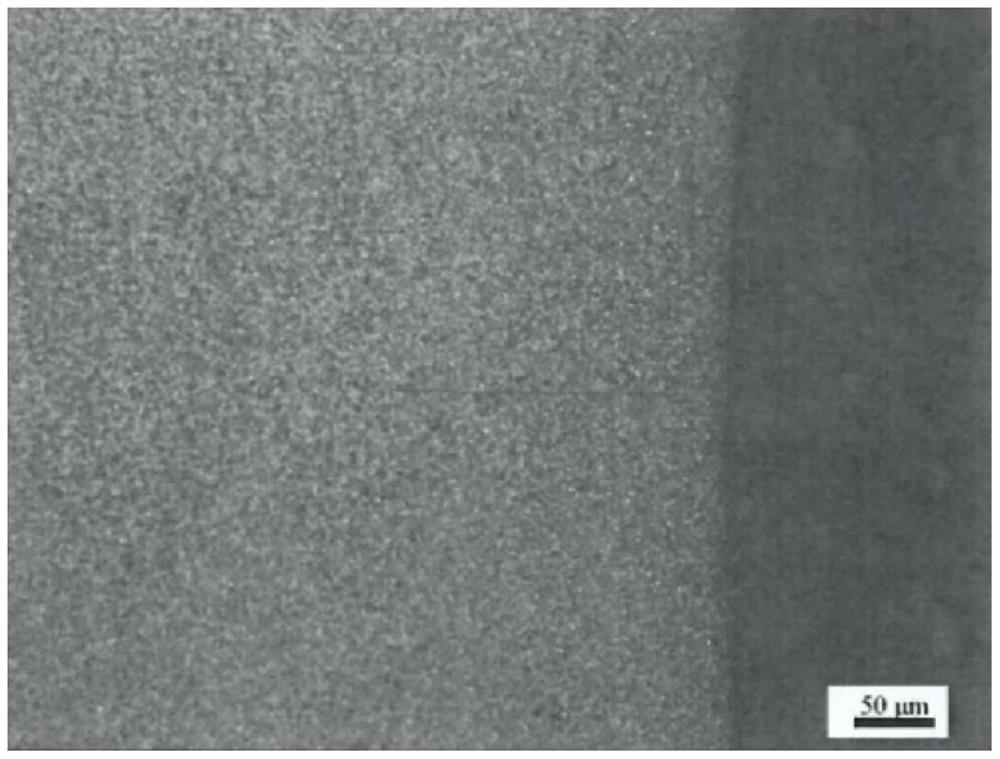

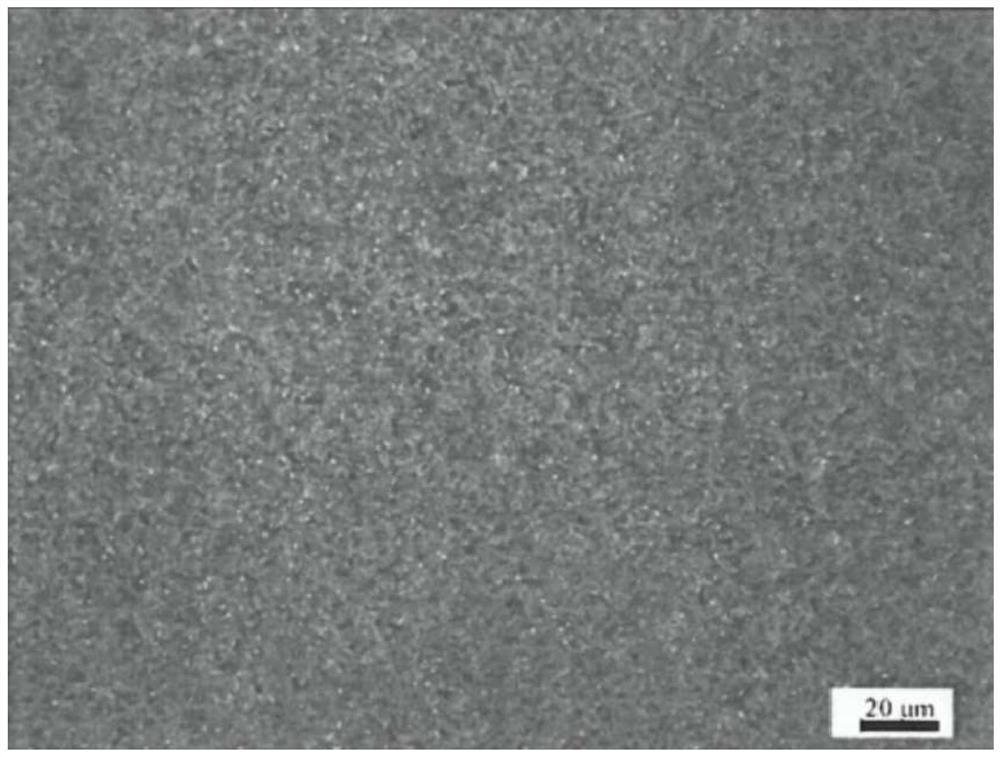

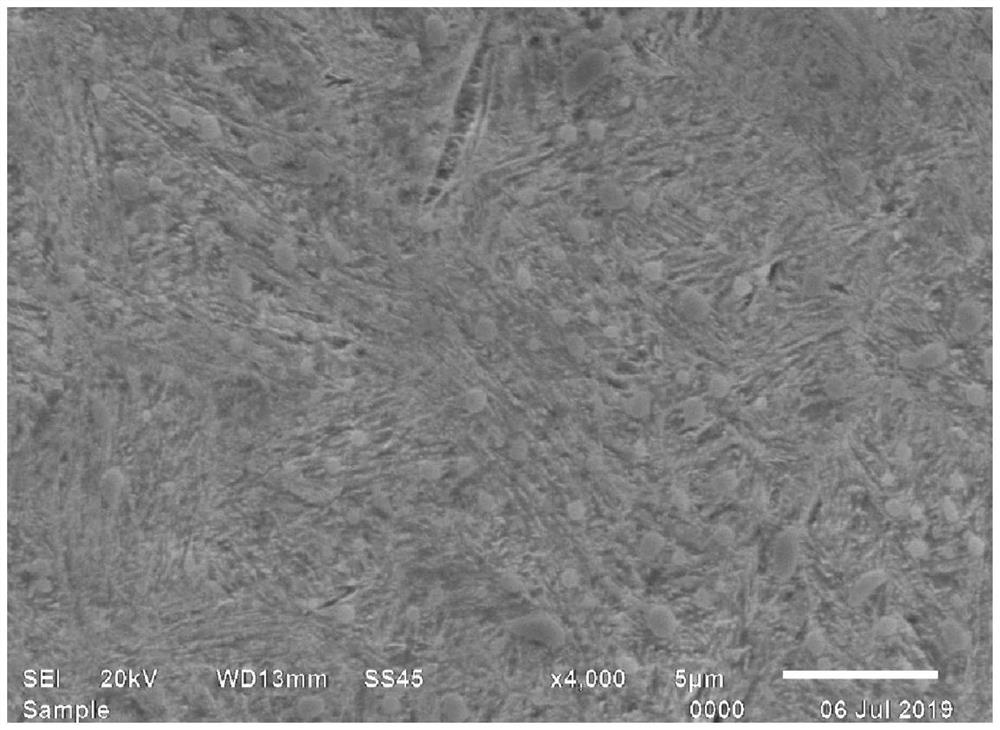

Image

Examples

Embodiment approach

[0025] The invention discloses a second embodiment of a high-carbon bearing steel preparation method, which includes the following steps:

[0026] Step 1, pressing the alloy powder into a green body in a mold, the alloy powder includes, by mass percentage, C: 0.97%, Si: 1.01%, Mn: 0.37%, Cr: 3.77%, Mo: 0.29%, and the rest are Iron and unavoidable impurities;

[0027] Step 2, vacuum sintering the green body to obtain a sintered body;

[0028] Step 3: Quenching the sintered body at 820-835°C, cooling it with oil to 92°C, washing it with cold water, and keeping it at 160-190°C for 200 minutes.

[0029] The present invention discloses a third embodiment of a high-carbon bearing steel preparation method, which includes the following steps:

[0030] Step 1. Press the alloy powder into a green body in a mold. The alloy powder includes, by mass percentage, C: 1.08%, Si: 1.13%, Mn: 0.49%, Cr: 3.96%, Mo: 0.34%, and the rest is iron and unavoidable impurities;

[0031] Step 2, vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com