Process for improving performance of carbonitriding layer through laser shock peening

A technology of laser shock strengthening and carbonitriding, which is used in metal material coating process, coating, solid diffusion coating, etc. and other problems, to achieve the effect of improving dislocation density, improving fatigue performance, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

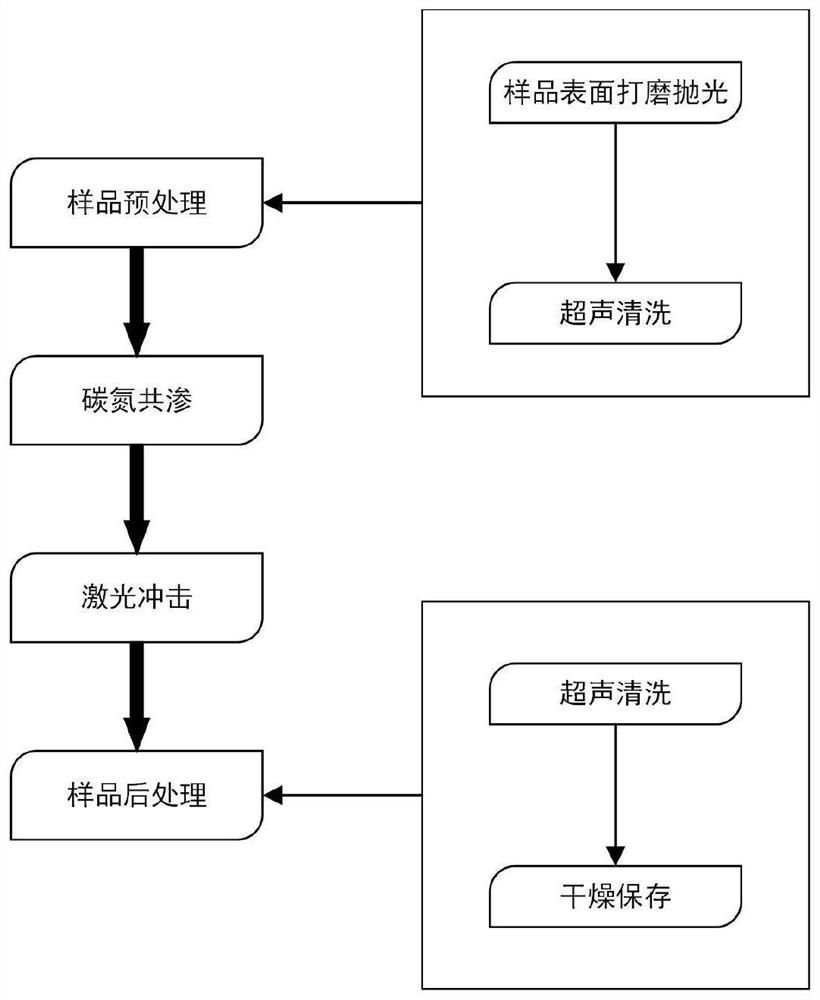

Method used

Image

Examples

Embodiment 1

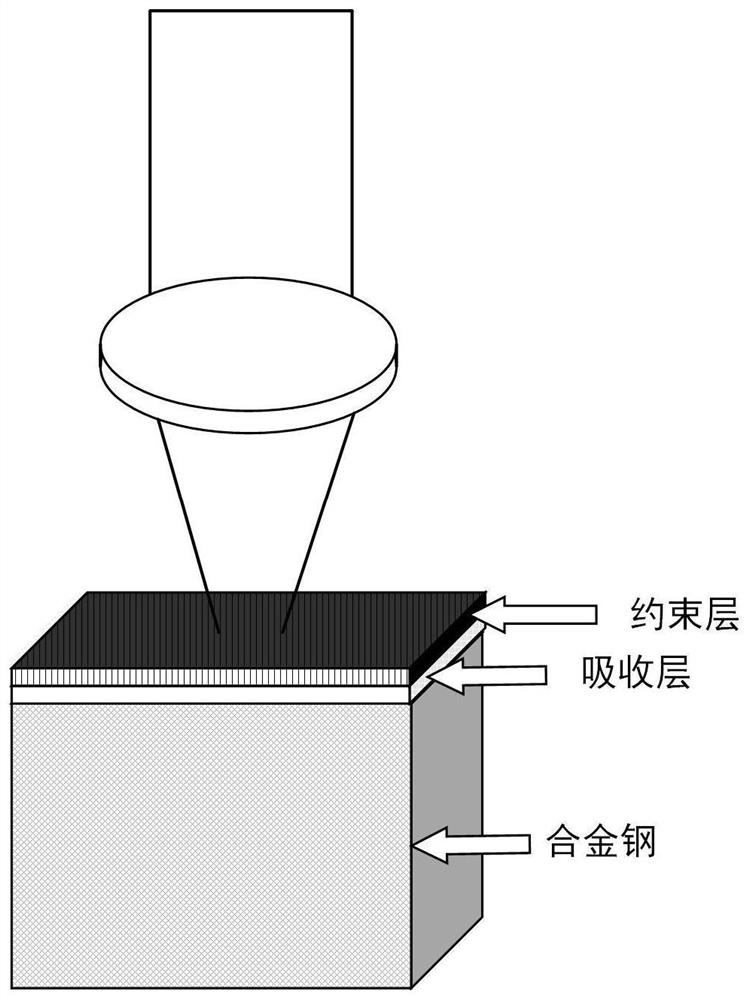

[0026] 20Cr2Mn2Mo is a high-quality alloy steel, commonly used in the manufacture of high-speed and heavy-duty gears. It must have good wear resistance, corrosion resistance and fatigue properties in engineering practice, so it needs to be surface modified, carbonitriding is one of the most common ways. The laser shock strengthening of the carbonitriding layer of the alloy steel is beneficial to refine the surface grains, generate residual compressive stress, and improve the service life of the alloy steel. In the present invention, carbonitriding is carried out to 20Cr2Mn2Mo first, and then laser shock strengthening is carried out, which specifically includes the following steps:

[0027] Step 1: First, cut the annealed 20Cr2Mn2Mo wire into a cuboid with a volume of 20×20×10mm, and then use 400#, 800#, 1200#, 1500#, 2000# sandpaper for step-by-step grinding; then use 0.5~3.5 The metallographic polishing agent of μm specification is polished step by step to make the surface r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com