Rice field ditch and building method

A paddy field and block technology, which is applied to the field of paddy canal irrigation, can solve the problems of daily maintenance and irrigation management, labor and time-consuming, inability to achieve irrigation management, and poor product quality. effect, the effect of improving water delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

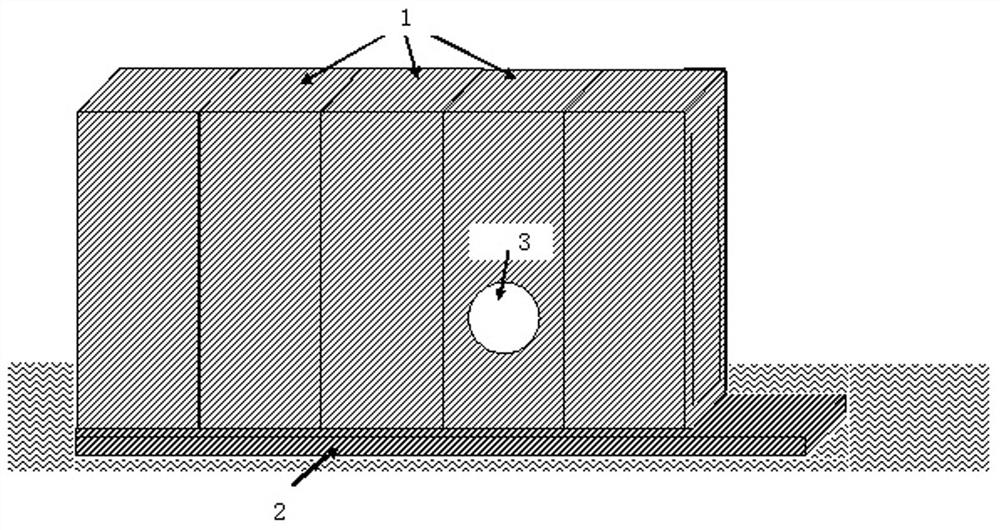

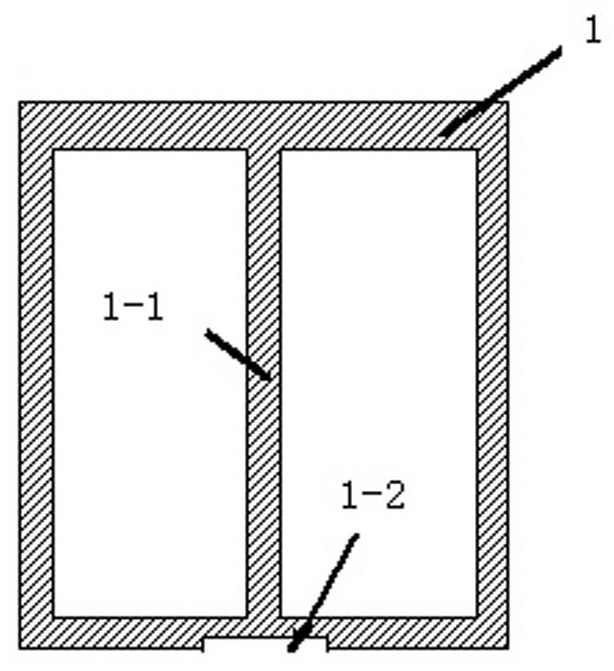

[0027] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

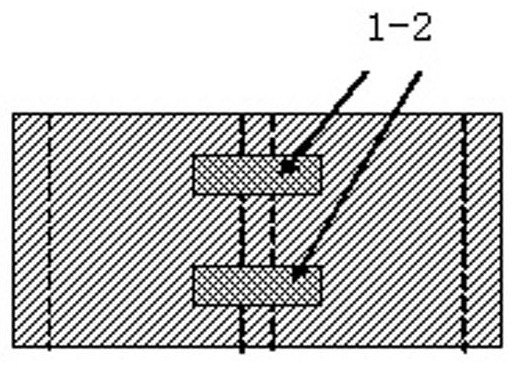

[0028] Such as Figure 1-6 As shown, the rice field ditch of the present invention is characterized in that it includes a group of block backing plates 2 that are plugged in each other, and a group of fixed projections 2-1 that are arranged on each block backing plate 2 are arranged in sequence on the Describe several block grooves 1 above the block backing plate 2, each block groove 1 is provided with a vertical vertical plate 1-1 in the middle, and the bottom surface of each block groove 1 is provided with two fixed grooves 1- 2. A water filling port 3 is provided on the side walls of any one block groove 1 and the vertical vertical plate 1-1 in the middle,

[0029] The two fixing grooves 1-2 on the bottom surface of each block groove 1 are plugged into the corresponding two fixing projections 2-1.

[0030] The water filling po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com