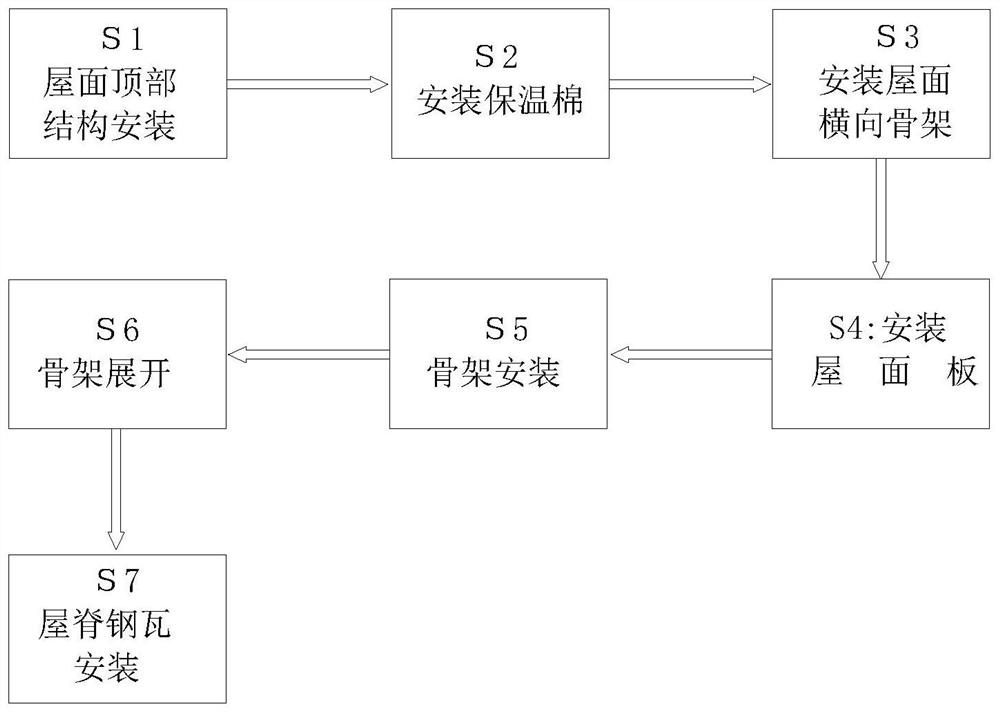

A method for installing steel structures in roof waterproof construction

An installation method and construction steel technology, applied in the direction of building components, building structures, buildings, etc., can solve the problems of high welding risk, low construction efficiency, and difficult construction, so as to achieve firm structure, fast installation efficiency, and improved roof ridge quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

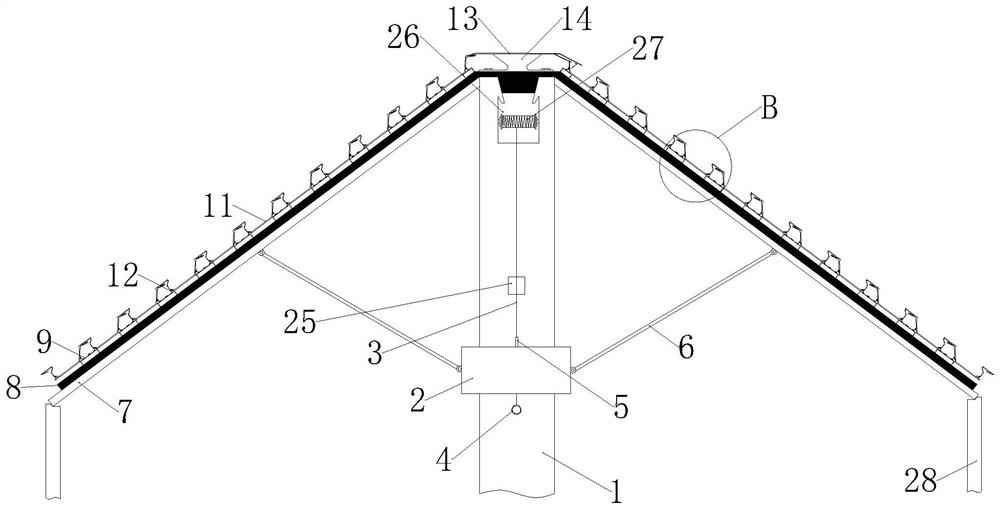

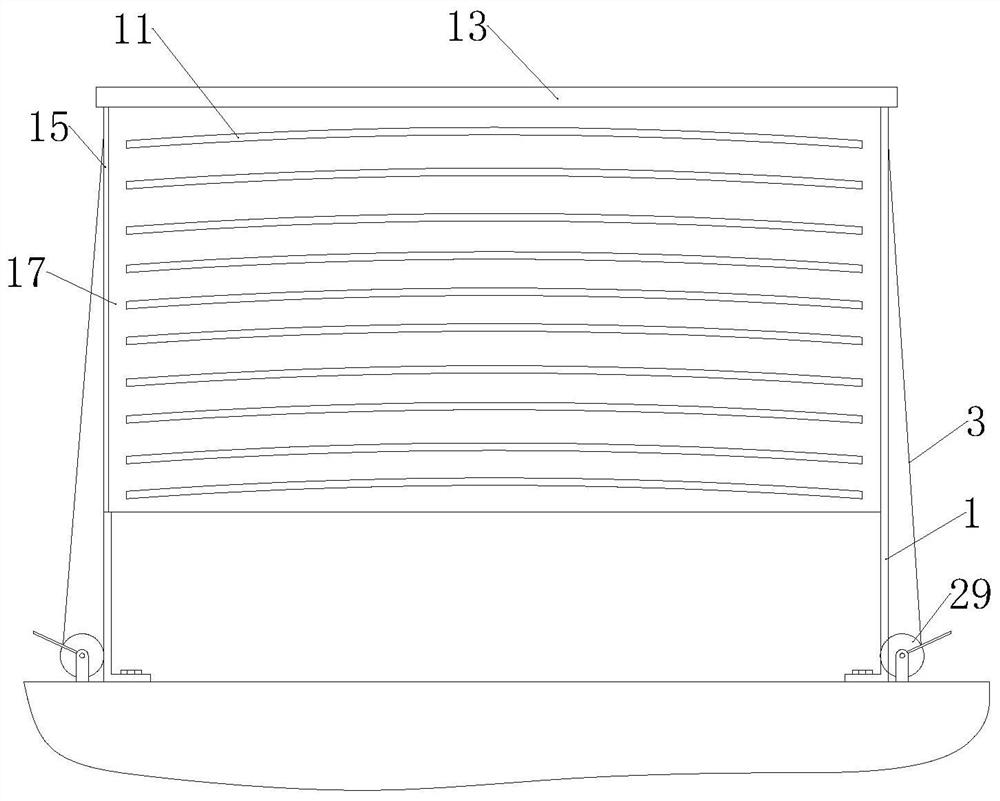

[0057] see Figure 1-9 , is a schematic diagram of the overall structure of a method for installing a building steel structure for roof waterproof construction;

[0058] A method for installing a building steel structure for roof waterproof construction. A method for installing a building steel structure for roof waterproof construction is specifically completed by a roof waterproof construction steel structure installation device. The installation device for a roof waterproof construction steel structure includes two vertical and fixed The support sandalwood bars 1 installed on the ground, and the wall skeletons 28 symmetrically installed on the left and right sides of each support sandalwood bars 1, the wall body skeletons 28 on each side are upright and fixedly installed on the ground, and each support sandalwood bars 1 The left and right sides of the wall and adjacent to the top of the support slat 1 are symmetrically hinged with a roof longitudinal framework 7, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com