A titanium alloy exhaust tongue valve

A titanium alloy and flap valve technology, which is applied to exhaust devices, lift valves, valve devices, etc., can solve the problems of valve cooling water jacket corrosion, corrosion leakage, valve disc position compensation failure, etc., to facilitate maintenance and replacement, improve Corrosion resistance, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

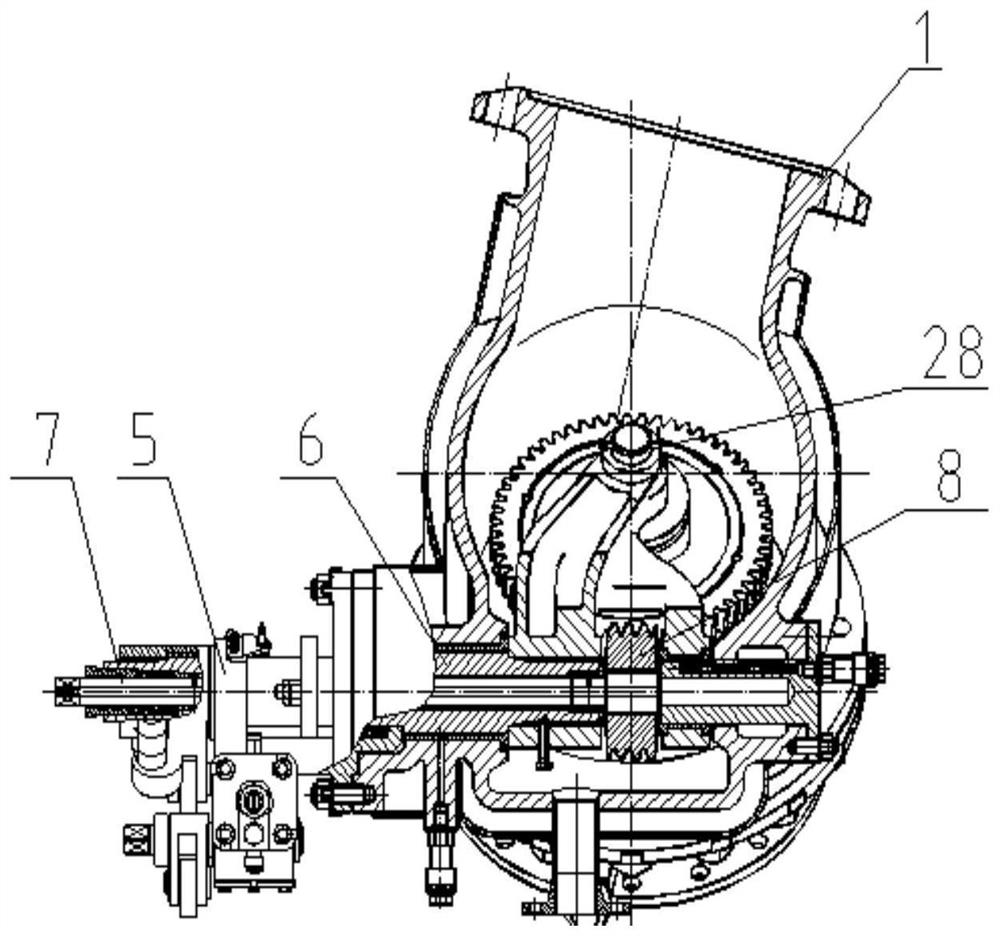

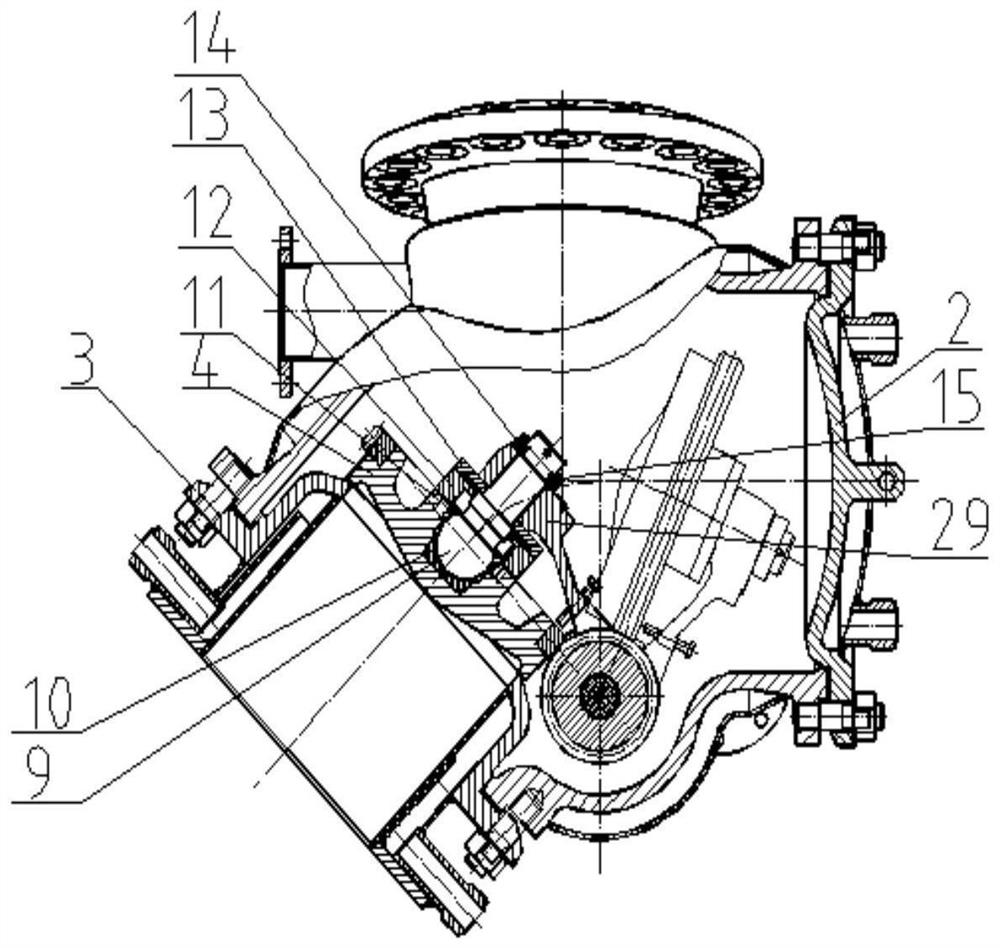

[0027] like figure 1 , 2 As shown, this embodiment provides a titanium alloy exhaust tongue valve, which includes a housing 1, a valve cover 2, a valve seat 3 and a valve disc 4, and also includes a hollow shaft 6, a long shaft 7, a hydraulic actuator 5, and a lever 29. The hollow shaft 6 is set on the long shaft 7, and the two move independently. One end of the hollow shaft 6 is connected with the lever 29, and the other end of the lever 29 is connected with the valve disc 4. The hollow shaft 6 passes through The hydraulic actuator 5 is driven to realize the opening or closing of the valve disc relative to the valve seat 3, and the tail end of the long axis 7 is connected with the valve disc 4 through a worm gear mechanism to realize the sealing connection between the valve disc and the valve seat.

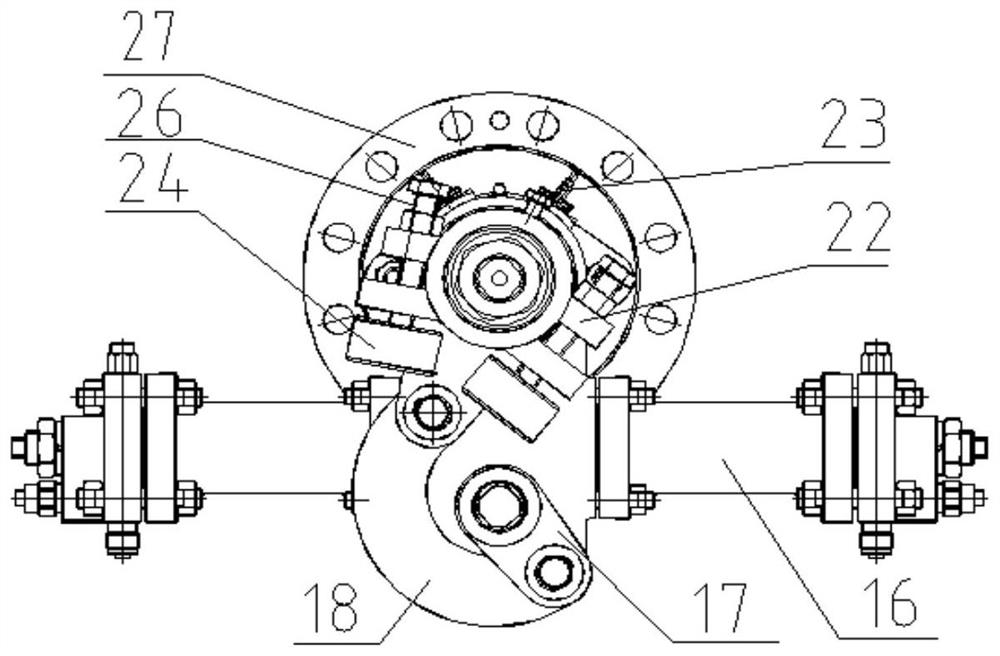

[0028] like image 3 , 4 As shown, the hydraulic actuator 5 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com