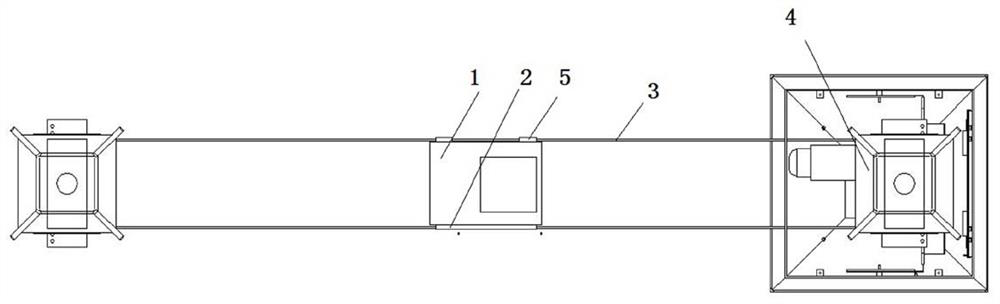

Channel silt and flow measuring system

A channel and flow measurement technology, applied in the field of measurement systems, can solve problems such as affecting the quality and efficiency of hydrological testing, limited ability to measure the environment, and affecting measurement accuracy, so as to reduce the probability of exposure to sunlight and rain, maintain stable measurement accuracy, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

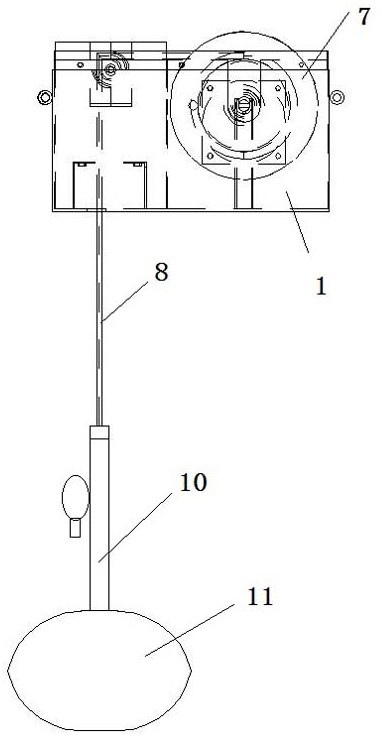

[0040] Embodiment 1: The ultrasonic transducer 13 is installed on the lower surface of the liquid level gauge, and two trigger ports are arranged along the axial direction of the liquid level gauge.

Embodiment 2

[0041] Embodiment 2: The ultrasonic transducer 13 is installed on the lower surface of the lead fish body, and two trigger ports are arranged along the axial direction of the lead fish body.

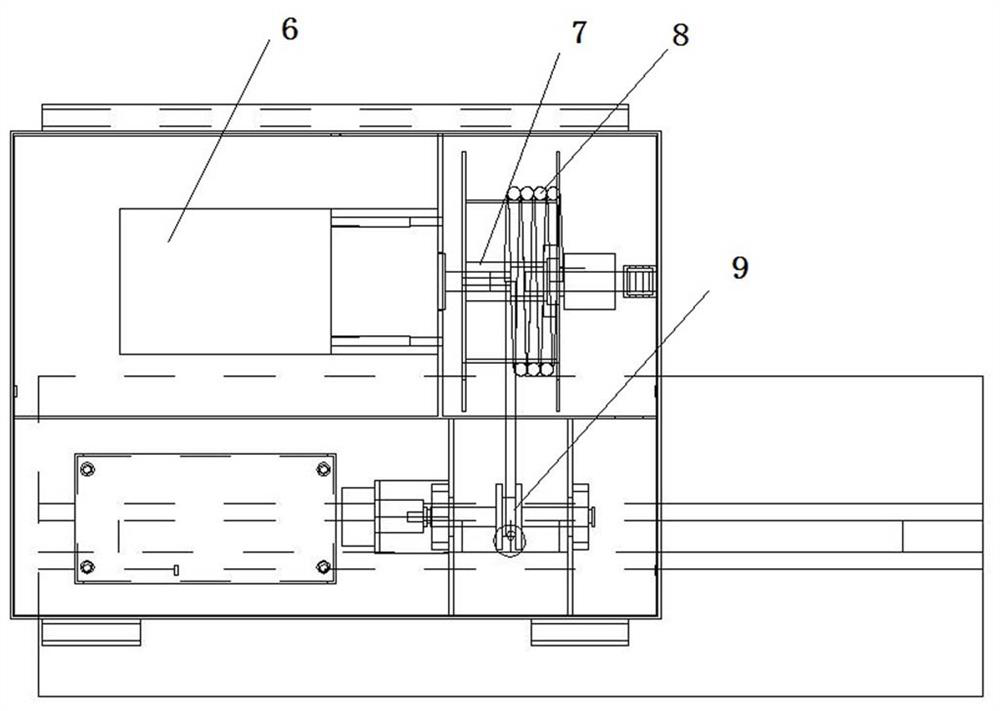

[0042]During use, the system disclosed by the present invention is used for real-time multi-point automatic measurement and early warning of channel section flow velocity, water level and silting conditions. When in use, it can realize vertical multi-point measurement, connect with the cloud through the communication structure, control the main body and the cloud computing center to realize the precise calculation of edge and cloud integration. When idle, the measuring device can be moved to the hidden box in time for hidden protection, reducing its long-term exposure in the field environment, prolonging its service life and reducing the difficulty of maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com