Large-scale structure hydrodynamic coefficient measuring device and method

A technology of hydrodynamic coefficient and large-scale structure, applied in the field of offshore oil machinery, can solve the problems such as the difficulty of combining the economy and accuracy of hydrodynamic coefficient well, the accuracy of hydrodynamic coefficient is not high, and the upflow area cannot be maintained, etc. Achieve the effect of reducing operating costs and risks, improving operating efficiency and safety factor, and reducing experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

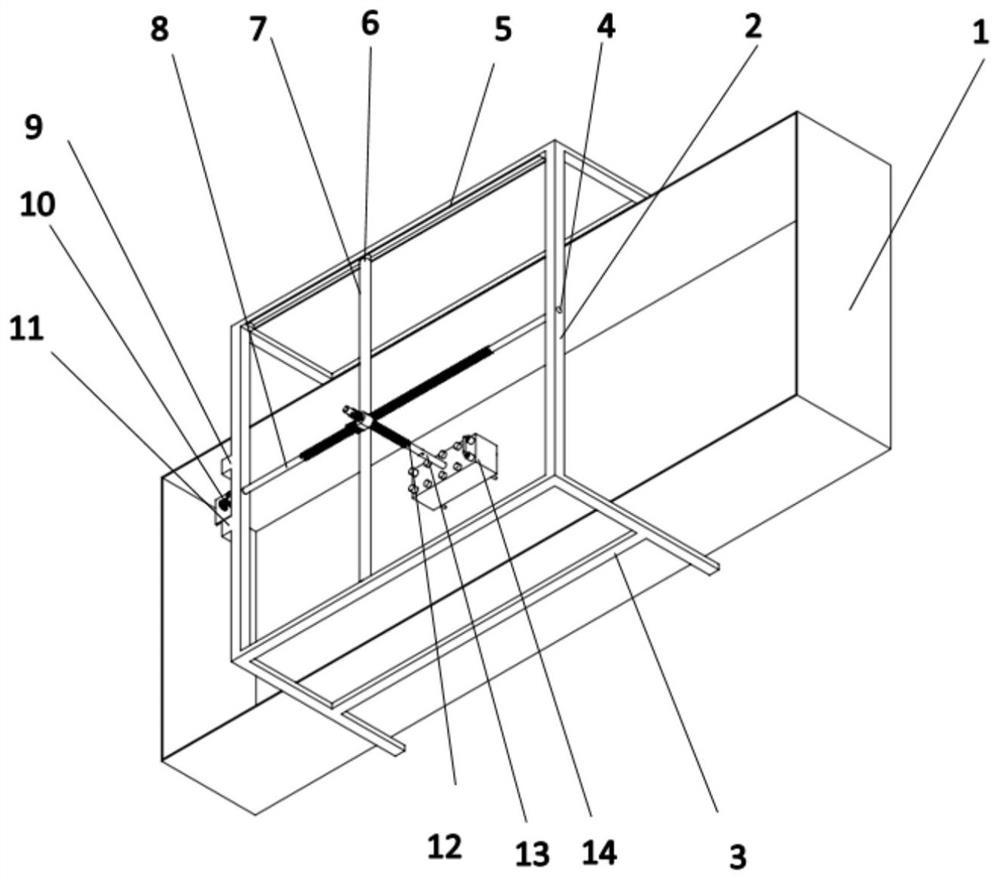

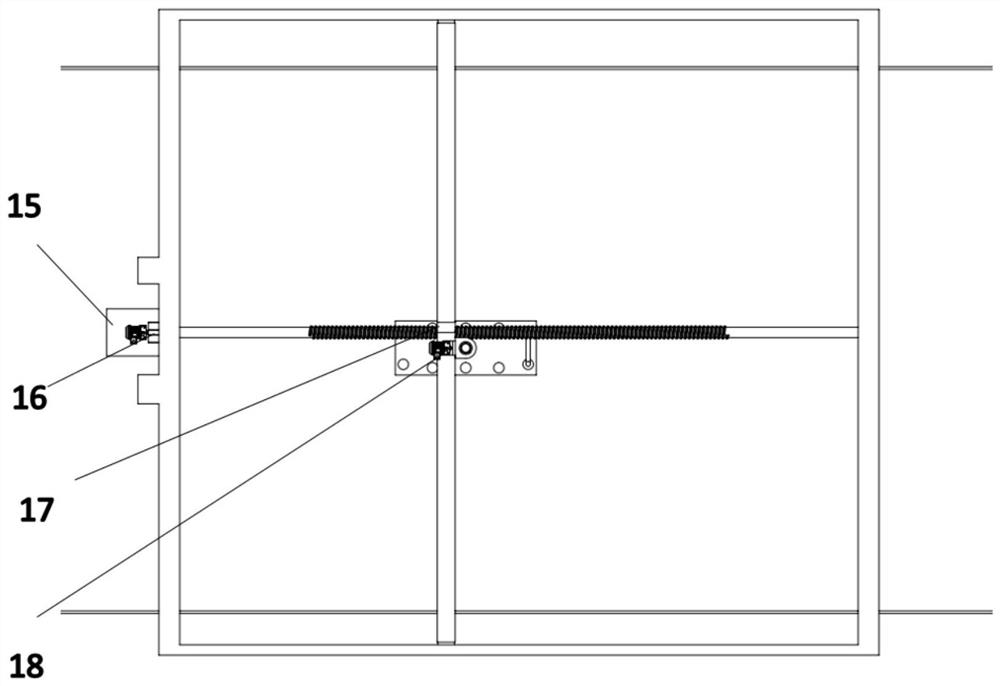

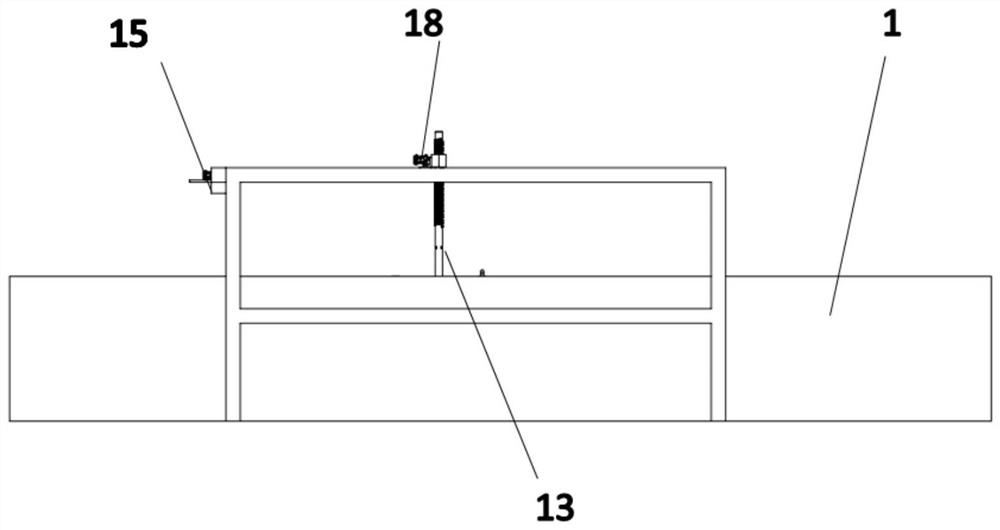

[0044] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, and are not exhaustive of all the embodiments. And in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

[0045] The inventor noticed in the course of the invention that when a small boat is used to drag the model at a fixed speed to measure the hydrodynamic coefficient, the frontal area in the water cannot be maintained, resulting in low accuracy of the measured hydrodynamic coefficient, thus affecting the actual Engineering is misleading. At present, the method of measuring the additional mass coefficient is mainly used to connect the four corners of the manifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com