Parameter calibration method, device and equipment and storage medium

A parameter calibration and data technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of unable to fix the working state of the engine, poor robustness of calibration results, waste of human resources and material resources, etc., to reduce the difficulty and cost of calibration, and improve the quality of calibration and the effect of calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

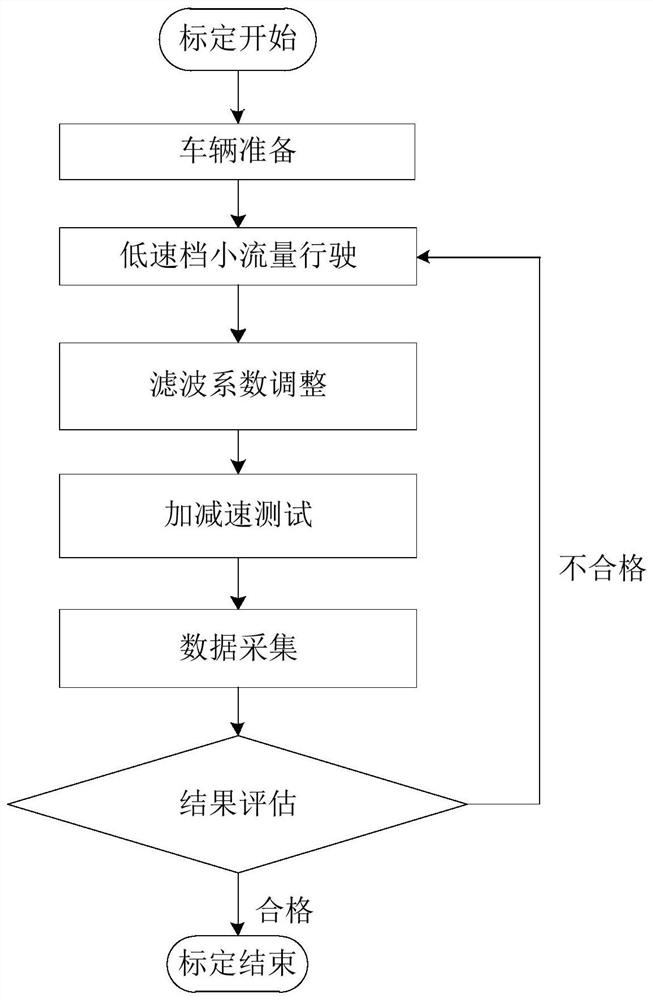

[0044] Figure 4 It is a flowchart of a parameter calibration method provided by Embodiment 1 of the present invention. This embodiment is applicable to the parameter calibration of the dynamic exhaust temperature model of the vehicle exhaust system. This method can be implemented by the parameter calibration device in the embodiment of the present invention To execute, the device may be implemented in software and / or hardware. The parameter calibration method provided in this embodiment specifically includes the following steps:

[0045] Step 110 , perform a step test of the engine intake mass flow rate by means of a chassis dynamometer.

[0046] Among them, the chassis dynamometer is an indoor bench test equipment used to test the performance of automobile power, multi-working condition emission indicators, and fuel indicators. The automobile chassis dynamometer simulates the road surface through the roller, calculates the road simulation equation, and simulates with the l...

Embodiment 2

[0071] Figure 5 It is a flow chart of an air intake mass flow step test method provided in Embodiment 2 of the present invention. This embodiment is based on the above embodiment, and specific optimization is carried out. 1. The first throttle opening threshold and the second throttle opening threshold are used to carry out the engine intake mass flow step test, which is optimized as: controlling the engine to work at a preset speed through the chassis dynamometer; controlling the throttle The pedal opening reaches the first accelerator opening threshold; if the variation range of the actual exhaust gas temperature is within the first preset temperature range, the accelerator pedal opening is controlled to reach the second accelerator opening threshold. For technical details not exhaustively described in this embodiment, reference may be made to any of the foregoing embodiments.

[0072] Specifically, refer to Figure 5 , the intake mass flow step test method specifically i...

Embodiment 3

[0089] Figure 6 It is a flow chart of a method for calibrating map parameters provided by Embodiment 3 of the present invention. This embodiment is based on the above-mentioned embodiments, and specific optimization is carried out. Based on the actual temperature data and all the input data, the Calibrate the map parameters of the dynamic exhaust temperature model, and optimize as follows: input all the input data into the dynamic exhaust temperature model; adjust the delay in the calibration map of the dynamic exhaust temperature model based on the actual temperature data filter coefficient. For technical details not exhaustively described in this embodiment, reference may be made to any of the foregoing embodiments.

[0090] Specifically, refer to Figure 6 , the map parameter calibration method specifically includes the following steps:

[0091] Step 310, input all the input data into the dynamic exhaust temperature model.

[0092] Step 320, adjusting the delay filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com