Industrial wireless remote control B system receiver mainboard test tool

An industrial wireless and testing tooling technology, which is applied in receiver monitoring, electronic circuit testing, signal transmission systems, etc., can solve the problems of unable to test the main board by pressing and fixing it, and it is difficult to fix multiple test main boards at the same time, so as to prevent missed detection and false detection Check and improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

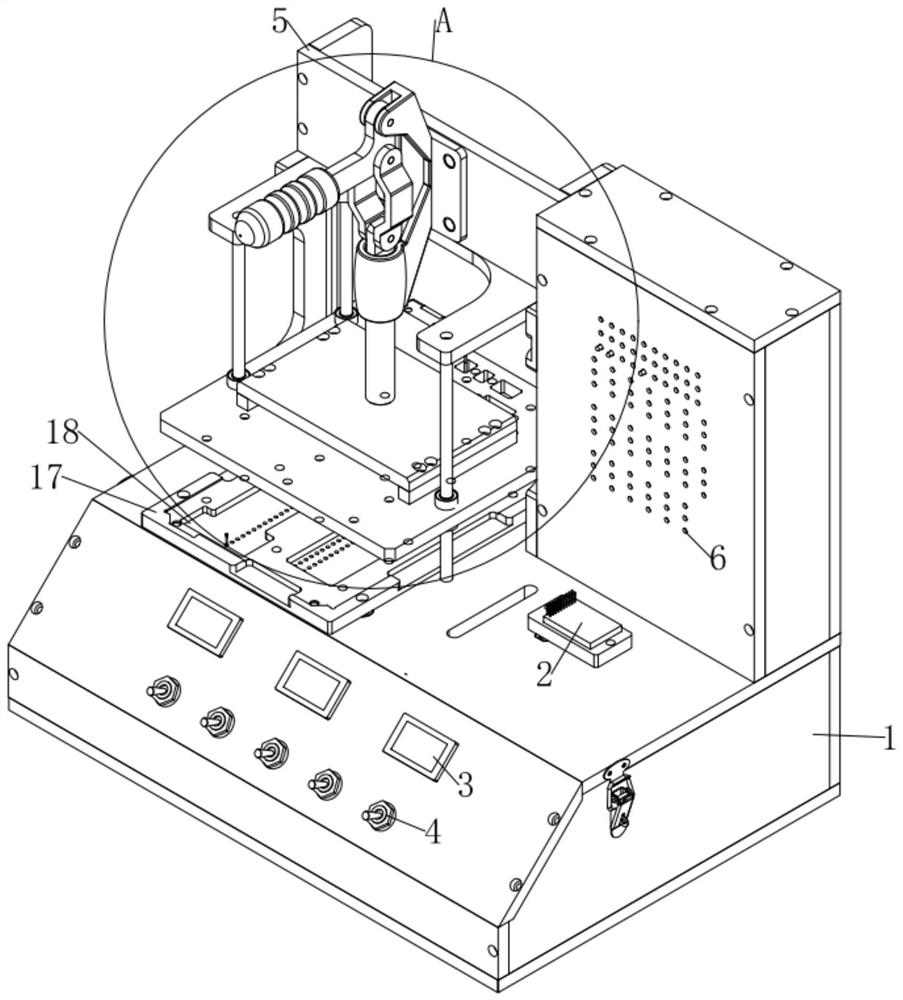

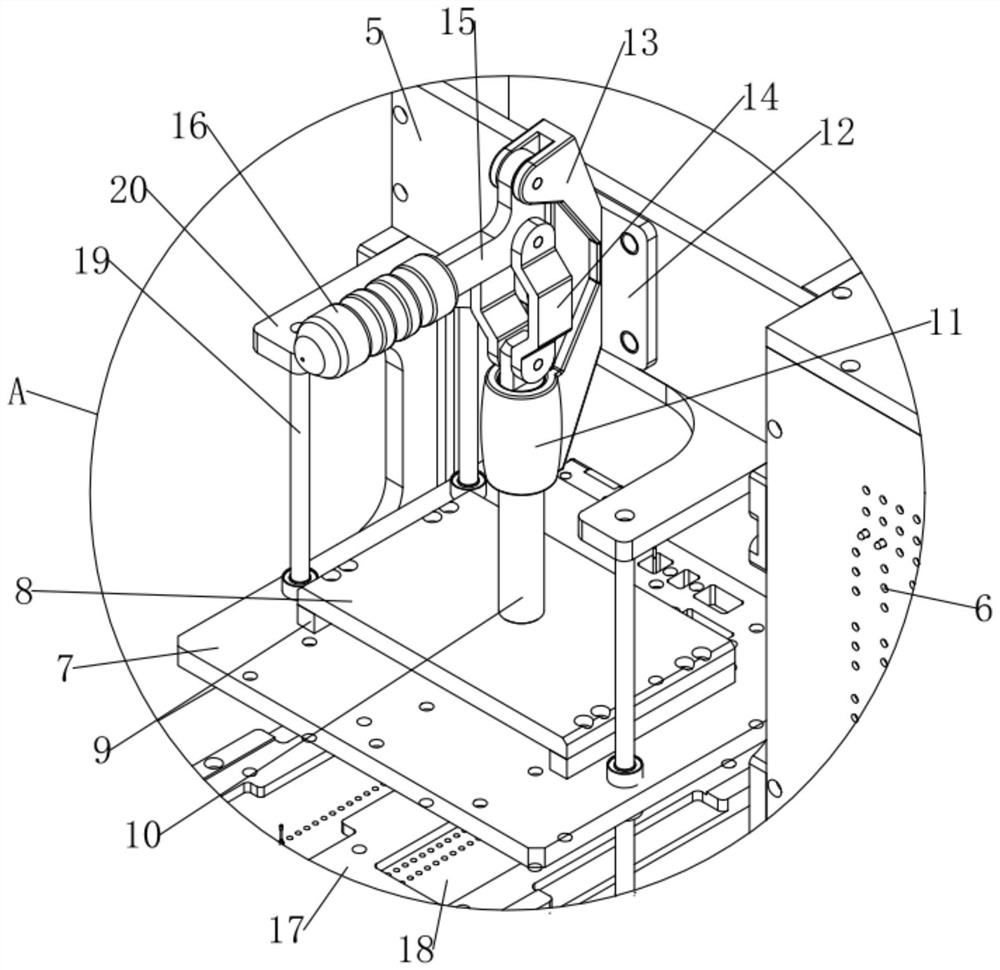

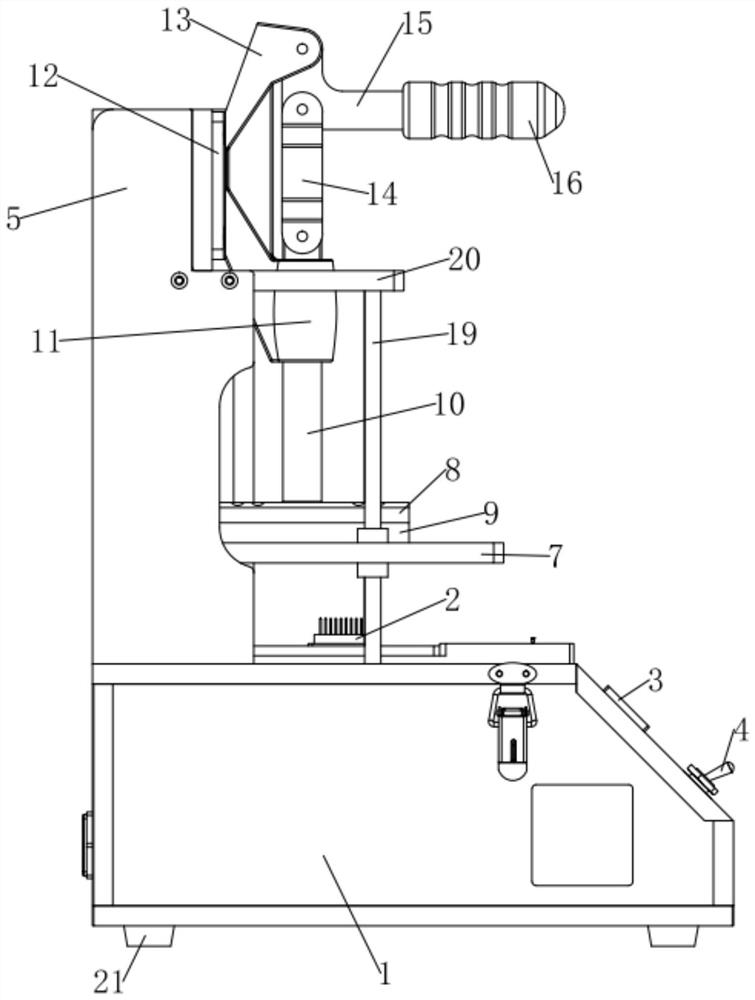

[0029] see figure 1 , a kind of industrial wireless remote control B system receiver mainboard test tooling, comprising a test machine 1, the upper end of the test machine 1 is fixedly connected with a support plate 5, the front end of the support plate 5 is fixedly connected with a first fixed plate 12, the first fixed The front end of the plate 12 is fixedly connected with a triangular connection block 13 and a casing 11, and a sliding rod 10 is movably inserted in the casing 11, and the upper part of the left and right ends of the sliding rod 10 is movably hinged with a rotating plate 14 through the first hinge shaft. The upper part of one end close to the rotating plate 14 is hinged with a triangular handle 15 through the second hinge shaft. Plate 8, two fixed blocks 9 are fixedly connected to the lower end of the clamp fixture 2, the lower ends of the two fixed blocks 9 are fixedly connected to the pressing plate 7, and the front end of the support plate 5 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com