A multi-variable equalization control method for power battery

A technology of equalization control and power battery, which is applied in the direction of charge equalization circuit, battery circuit device, arrangement of multiple synchronous batteries, etc. It can solve the problems of difficult to meet the rapidly changing working conditions, high cost of the equalization system, and low equalization speed. Achieve the effects of high balanced energy transfer efficiency, increased capacity utilization, and improved remaining life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

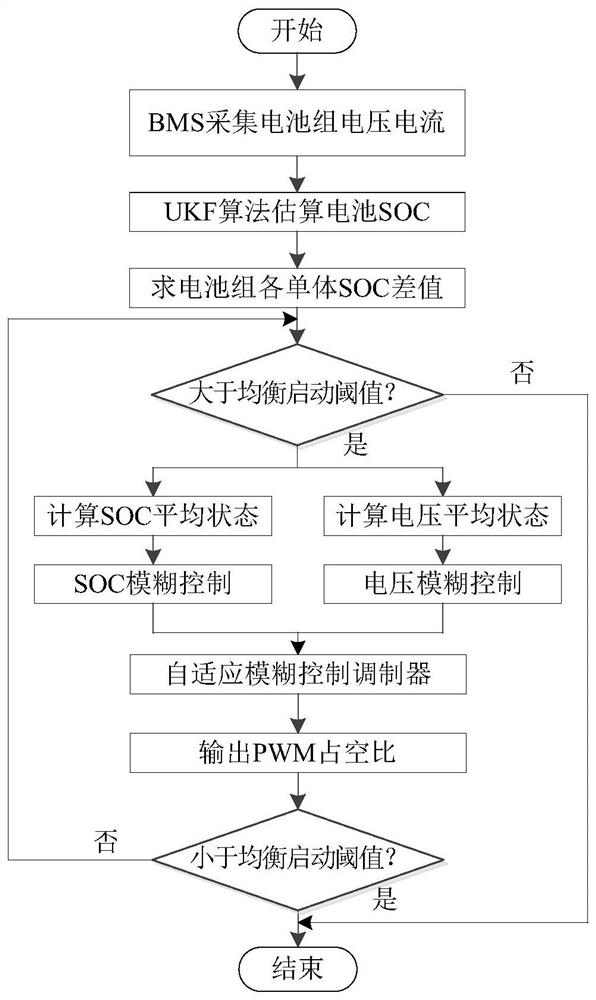

[0050] refer to Figures 1 to 10 , which is the first embodiment of the present invention, which provides a multi-variable equalization control method for a power battery, including:

[0051] S1: Establish a balanced circuit topology, and use BMS to collect the voltage and current of the battery pack. It should be noted that establishing a balanced circuit topology includes:

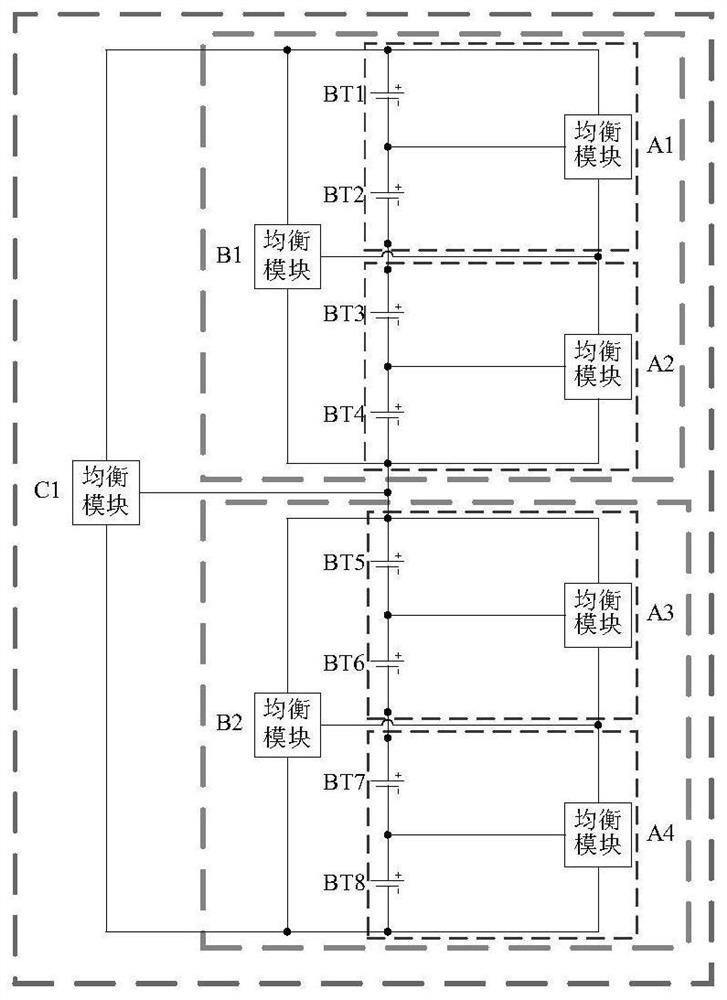

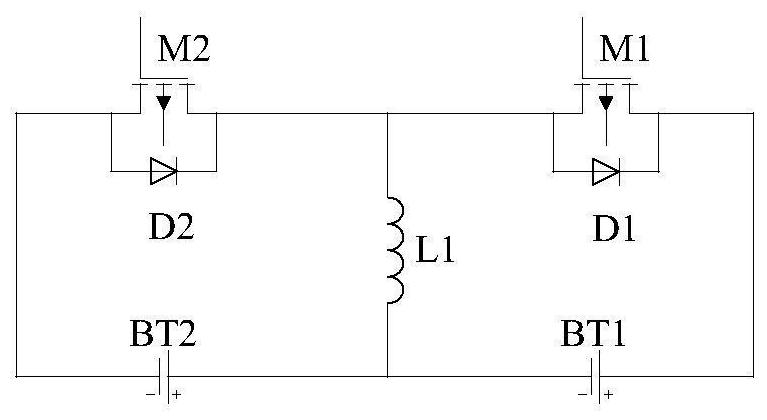

[0052] Divide the single cells in the battery pack into several equalization groups and arrange them into a pyramid structure for hierarchical equalization control; carry out parameter design and energy analysis of the equalization circuit and calculate the influence of stray parameters on the equalization circuit;

[0053] Further, referring to Figure 2(a), the single cells in the battery pack are divided into several equalization groups, and every two adjacent battery cells and the equalization sub-module installed between them form the first-layer equalization group, A1, A2... An is the first level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com