Copper wire production line and manufacturing process of copper wire

A production line and copper wire technology, which is applied in the field of copper wire manufacturing, can solve problems such as difficult post-processing, pollution, and large amount of acid solution, and achieve the effects of reducing usage, reducing pollution, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

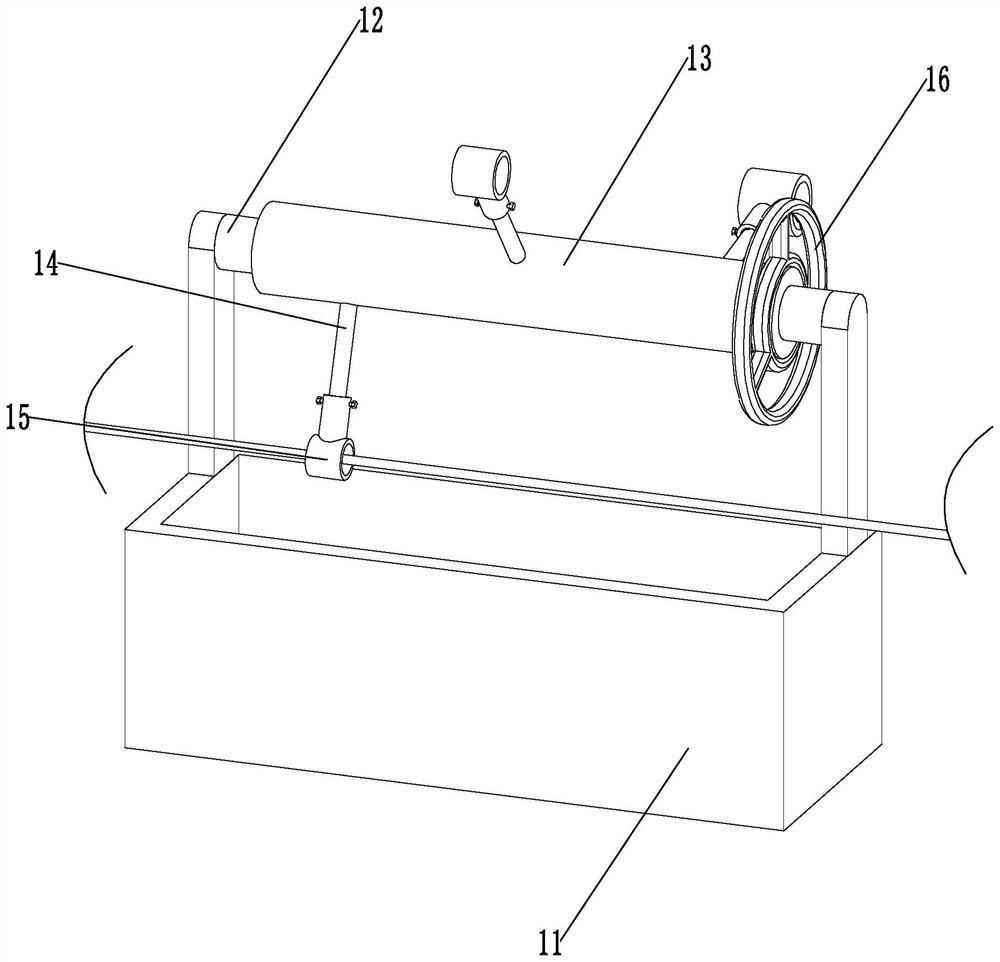

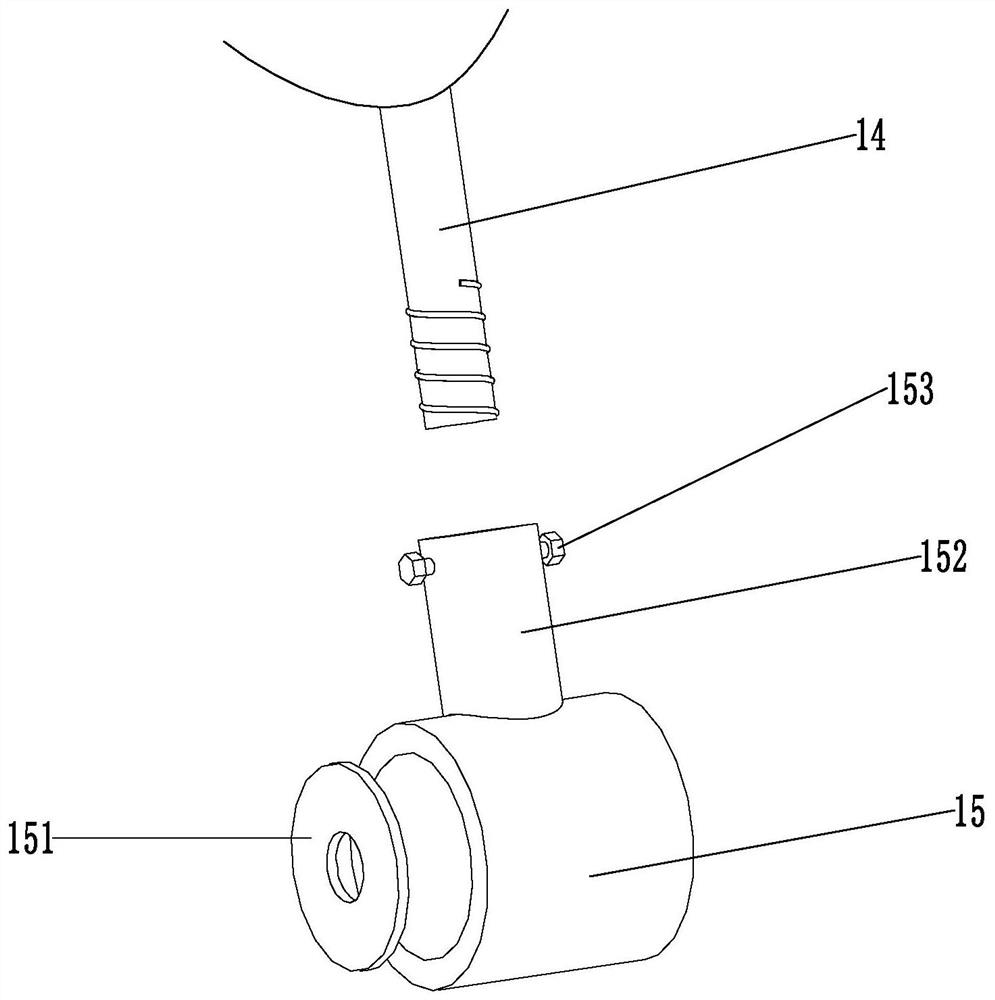

[0048] The following is attached Figure 1-4 The application is described in further detail.

[0049] The embodiment of the present application discloses a copper wire production line and a manufacturing process thereof.

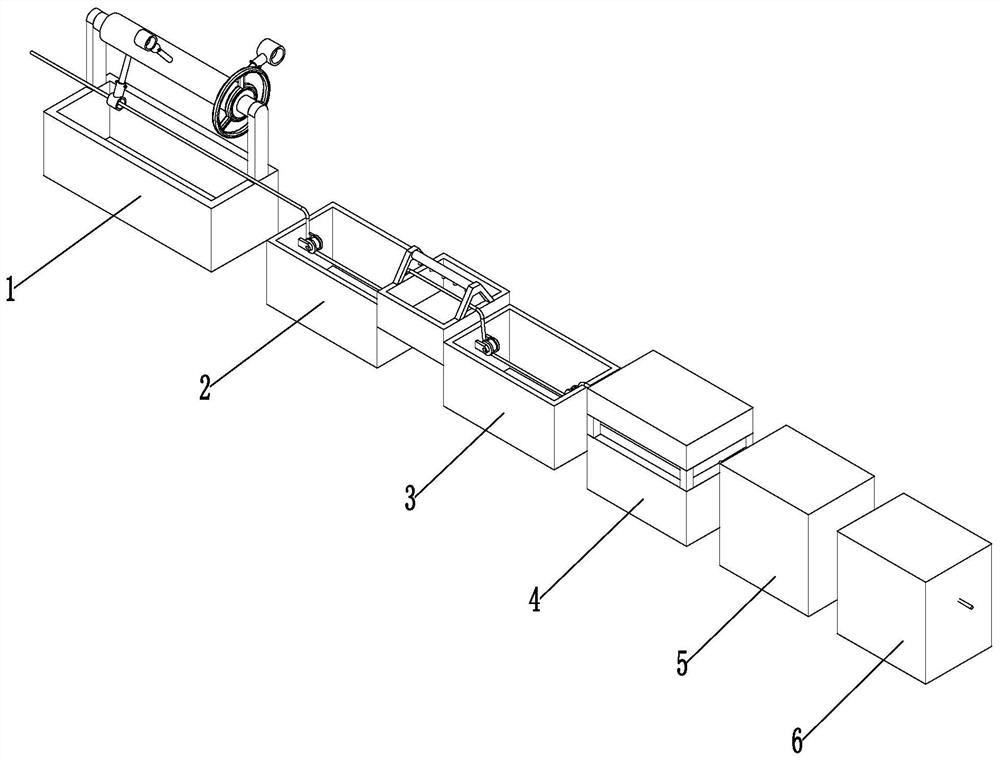

[0050] refer to figure 1A copper wire production line includes a primary scraping device 1, a pickling tank 2, a water washing tank 3, a secondary scraping device 4, a wire drawing machine 5 and an annealing furnace 6 arranged in sequence. The setting of the primary scraping device 1 can scrape off the metal oxide on the surface of the copper rod, and pretreat the surface of the copper rod; the copper rod coming out of the primary scraping device 1 enters the pickling pool 2 for cleaning. After further cleaning, most of the oxides on the surface of the copper rod after pickling have been completely removed. The copper rod after pickling enters in the washing pool 3, and the acid solution on the surface of the copper rod is cleaned. The copper rod output ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap