Intelligent pencil sharpener assembling equipment and working method thereof

A technology for assembling equipment and pencil sharpeners, which is applied in the field of automation, can solve the problems of easy cutting of small knives, unsafe, inconvenient use, etc., and achieve the effect of reducing the number of equipment, improving processing quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

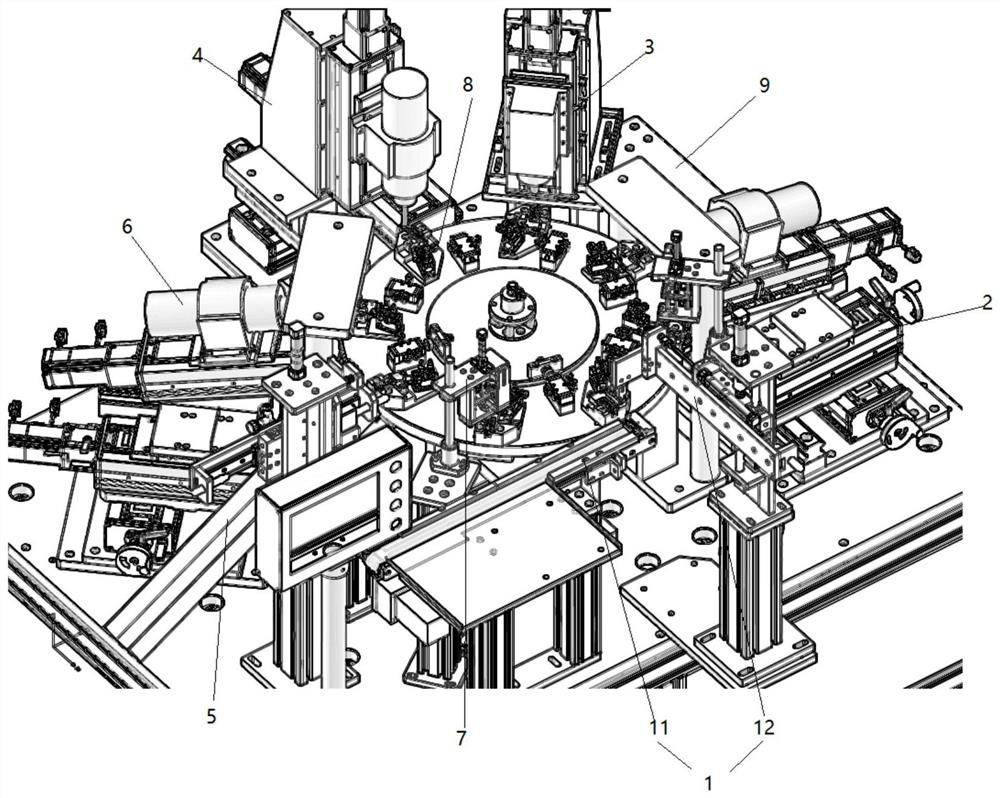

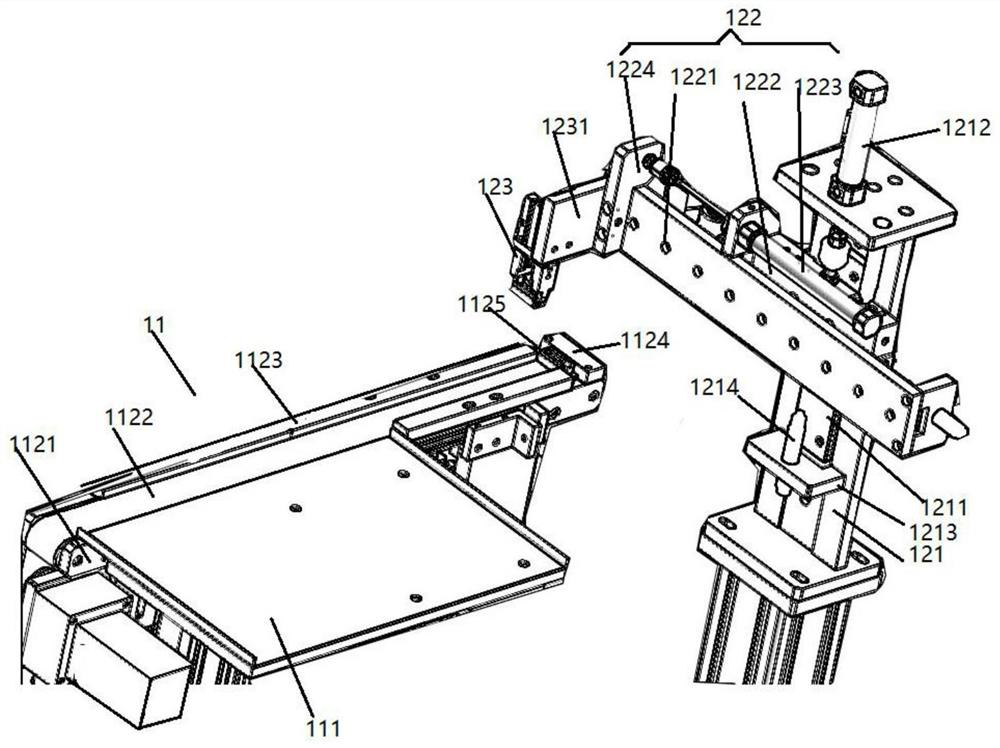

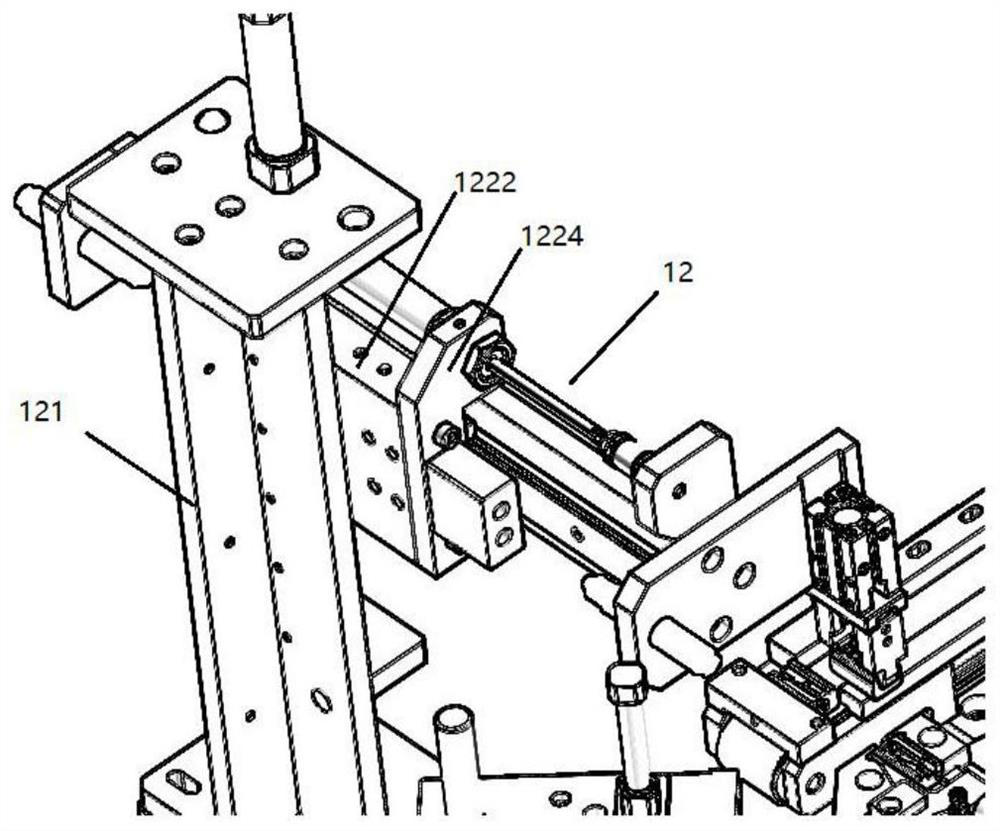

[0061] As shown in the figure, an assembly device for a pencil sharpener includes: a feeding device 1, a first punching device 2 for processing the installation hole of a pencil sharpener, and a second punching device for processing screw holes 3. Plane milling device 4, discharge device 5, third punching device 6, a set of detection devices 7 and a set of tooling 8 for placing products, the feeding device 1, the first punching device 2, the first The second punching device 3, the milling device 4, the discharge device 5, the third punching device 6 and a group of detection devices 7 are all arranged on the frame, and the frame is provided with a workbench 9, and the workbench 9 is provided with a set of tooling 8 for placing products, the feeding device 1, the first punching device 2, the second punching device 3, the plane milling device 4, the discharging device 5, the third punching device 6 And a group of detection devices 7 are all arranged on the outside of the workbenc...

Embodiment 2

[0080] As shown in the figure, an intelligent pencil sharpener assembly equipment includes: a feeding device 1, a first punching device 2 for processing the installation hole of the pencil sharpener, and a second punching device 3 for processing screw holes , milling device 4, discharge device 5, the third punching device 6, a group of detection devices 7 and a group of tooling 8 for placing products, the feeding device 1, the first punching device 2, the second The punching device 3, the plane milling device 4, the discharging device 5, the third punching device 6 and a group of detection devices 7 are all arranged on the frame, and the frame is provided with a workbench 9, and the workbench 9 There is a set of tooling 8 for placing products, the feeding device 1, the first punching device 2, the second punching device 3, the milling device 4, the discharging device 5, the third punching device 6 and A group of detection devices 7 are all arranged on the outside of the workbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com