A kind of butyl tape primer for roofing tpo waterproof coiled material and its application

A technology of butyl tape and waterproof membrane, which is applied in the direction of roofing, adhesives, roof coverings, etc., can solve the problems of butyl tape performance degradation, reduce impact, improve durability and waterproof sealing effect, and improve bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

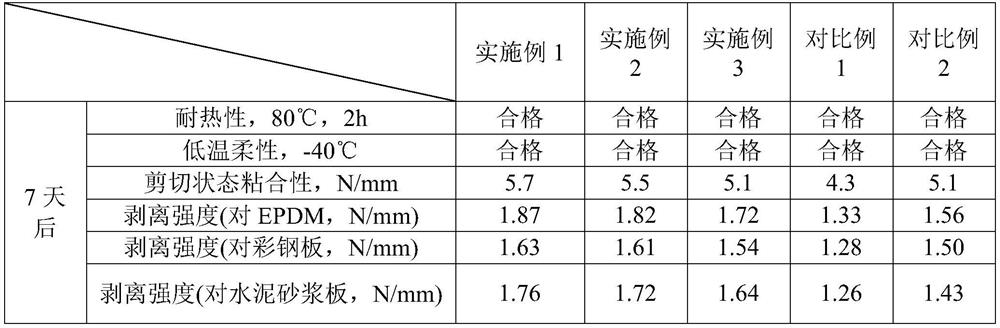

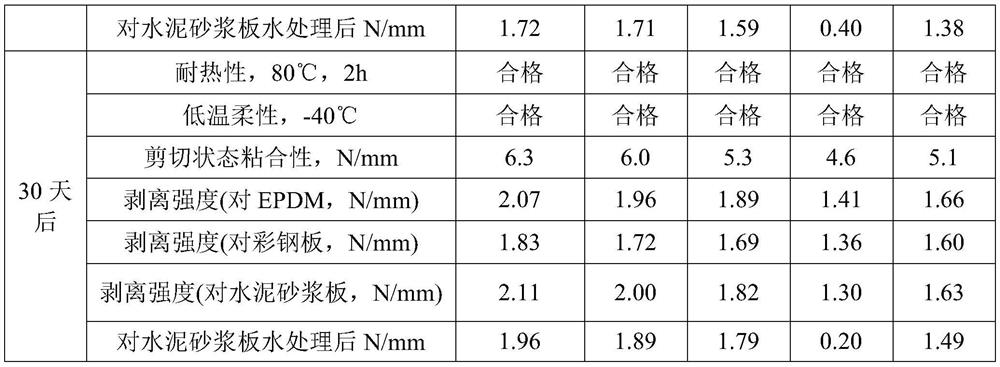

Embodiment 1

[0043] This example provides a kind of butyl tape primer and its application in the butyl tape waterproof sealing that TPO waterproof roll material is used, by weight percentage, the content of each component of described primer is as follows: Bromine Butyl rubber 12.7%; terpene resin 6.3%; p-benzoquinone dioxime 1%; xylene 80%.

[0044] The preparation method of the primer is as follows: cut bromobutyl rubber into small pieces and put them into a reaction kettle, add terpene resin, p-benzoquinone dioxime, and xylene to mix, dissolve and stir at a temperature of 30°C, After homogenizing for 120 minutes, the finished product was obtained.

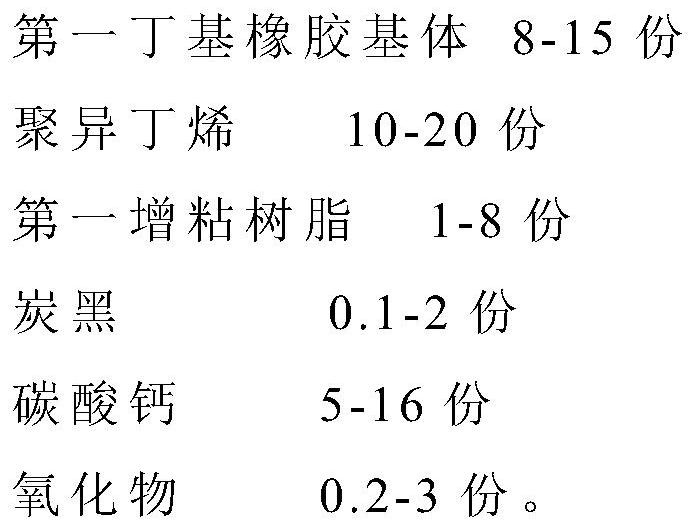

[0045] In parts by mass, the content of each component of the butyl tape in this example is as follows: 3 parts of butyl rubber; 7 parts of bromobutyl rubber; 14 parts of polyisobutylene; 4 parts of terpene resin; 1 part of carbon black ; 10 parts of calcium carbonate; 0.5 parts of zinc oxide; 0.5 parts of lead dioxide.

[0046] The prepar...

Embodiment 2

[0049] This example provides a kind of butyl tape primer and its application in the butyl tape waterproof sealing that TPO waterproof roll material is used, by weight percentage, the content of each component of described primer is as follows: Bromine Butyl rubber 13.3%; terpene resin 6.7%; p-benzoquinone dioxime 1%; xylene 79%.

[0050] The preparation method of the primer is as follows: cut bromobutyl rubber into small pieces and put them into a reaction kettle, add terpene resin, p-benzoquinone dioxime, and xylene to mix, dissolve and stir at a temperature of 30°C, After homogenizing for 120 minutes, the finished product was obtained.

[0051] In parts by mass, the content of each component of the butyl tape in this example is as follows: 3 parts of butyl rubber; 7 parts of bromobutyl rubber; 14 parts of polyisobutylene; 4 parts of terpene resin; 1 part of carbon black ; 10 parts of calcium carbonate; 0.5 parts of zinc oxide; 0.5 parts of lead dioxide.

[0052] The prepar...

Embodiment 3

[0055] This example provides a kind of butyl tape primer and its application in the butyl tape waterproof sealing that TPO waterproof roll material is used, by weight percentage, the content of each component of described primer is as follows: Bromine Butyl rubber 15.0%; terpene resin 5.0%; p-benzoquinone dioxime 1%; xylene 79%.

[0056] The preparation method of the primer is as follows: cut bromobutyl rubber into small pieces and put them into a reaction kettle, add terpene resin, p-benzoquinone dioxime, and xylene to mix, dissolve and stir at a temperature of 30°C, After homogenizing for 120 minutes, the finished product was obtained.

[0057] In parts by mass, the content of each component of the butyl tape in this example is as follows: 3 parts of butyl rubber; 7 parts of bromobutyl rubber; 14 parts of polyisobutylene; 4 parts of terpene resin; 1 part of carbon black ; 10 parts of calcium carbonate; 0.5 parts of zinc oxide; 0.5 parts of lead dioxide.

[0058] The prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com