Grass-proof cloth and preparation method thereof

A grass-proof cloth and fiber cloth technology, applied in the field of grass-proof cloth, can solve the problems of poor weather resistance of the grass-proof cloth, influence of the strength and service life of the grass-proof cloth, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

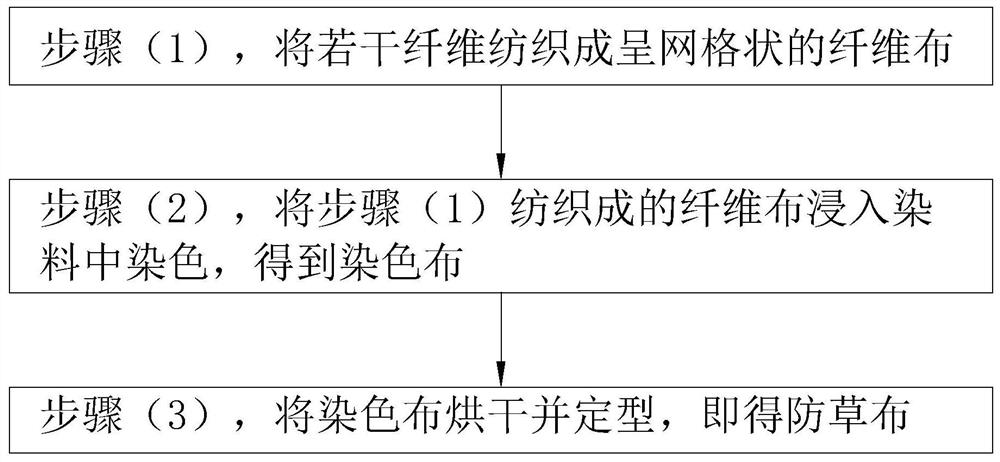

[0052] refer to figure 1 , the application discloses a preparation method of grass-proof cloth, comprising the following steps:

[0053]In step (1), a number of polyester fibers are arranged in parallel and wound on the I-shaped wheel, and then a number of polyester fibers are woven into a fiber cloth with a grid structure with triangular holes through a loom, and the weed-proof cloth is controlled. The fabric cover factor is 75%, and the thickness of the control grass-proof cloth is 0.5mm.

[0054] In step (2), the dyeing agent, polyvinyl acetate emulsion, anti-ultraviolet agent and water are stirred and mixed uniformly to form a dye, and then the fiber cloth prepared in step (1) is dipped in the dye for dyeing to obtain a dyed cloth.

[0055] In step (3), the dyed cloth is heated, dried and shaped by a dryer, and the heating temperature is controlled at 200° C. to obtain the weed-proof cloth.

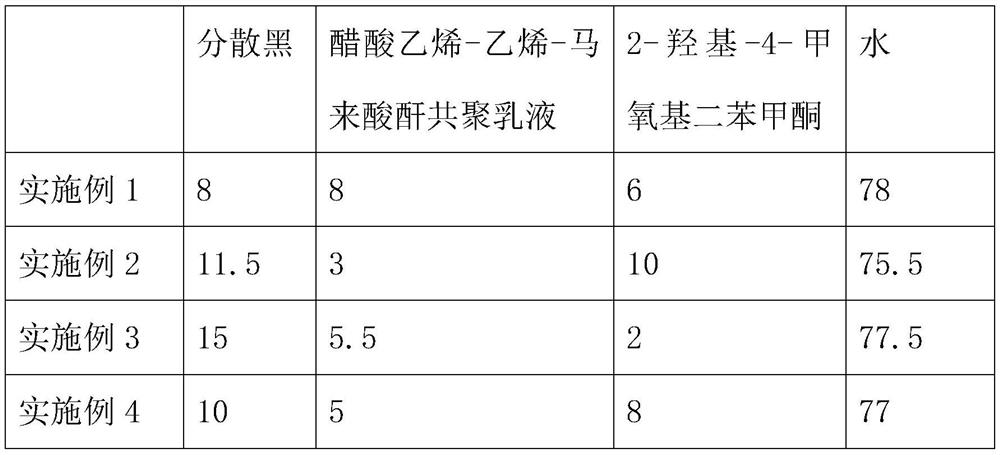

[0056] In this embodiment, the dyeing agent is disperse black; the polyvinyl ac...

Embodiment 2

[0059] The difference with embodiment 1 only lies in:

[0060] In the step (1), the fabric coverage factor of the grass-proof cloth is controlled to be 83%, and the thickness of the grass-proof cloth is controlled to be 1.0 mm.

[0061] Wherein, the addition amount of each component of the dye is shown in Table 1, and the dosage unit of each component in Table 1 is kg.

Embodiment 3

[0063] The difference with embodiment 1 only lies in:

[0064] In the step (1), the fabric coverage factor of the grass-proof cloth is controlled to be 90%, and the thickness of the grass-proof cloth is controlled to be 1.5 mm.

[0065] Wherein, the addition amount of each component of the dye is shown in Table 1, and the dosage unit of each component in Table 1 is kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com