Cement-free pervious concrete brick

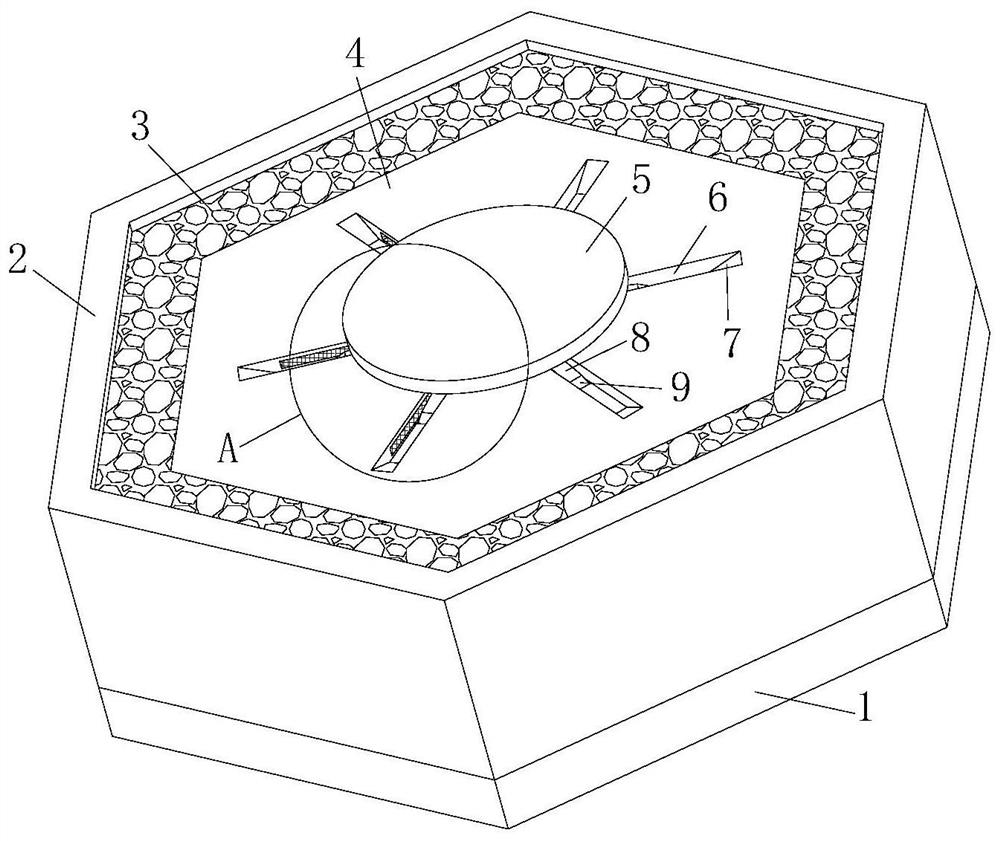

A permeable concrete, cement-free technology, used in climate change adaptation, roads, pavements paved with prefabricated blocks, etc., can solve the problem that the urban heat island effect cannot be effectively reduced, the rainwater cannot be trapped on the road surface, and the permeable bricks can penetrate quickly. problems, to reduce the urban heat island effect, avoid excessive pressure damage, and reduce the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

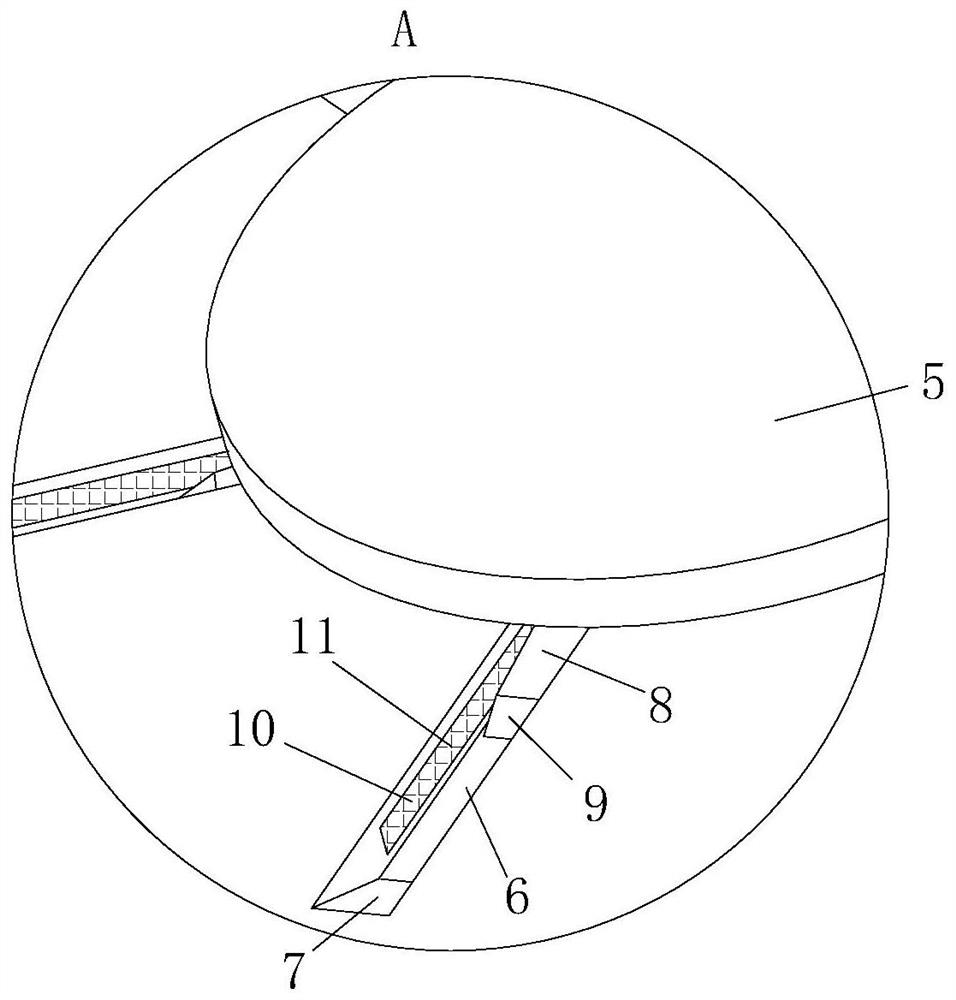

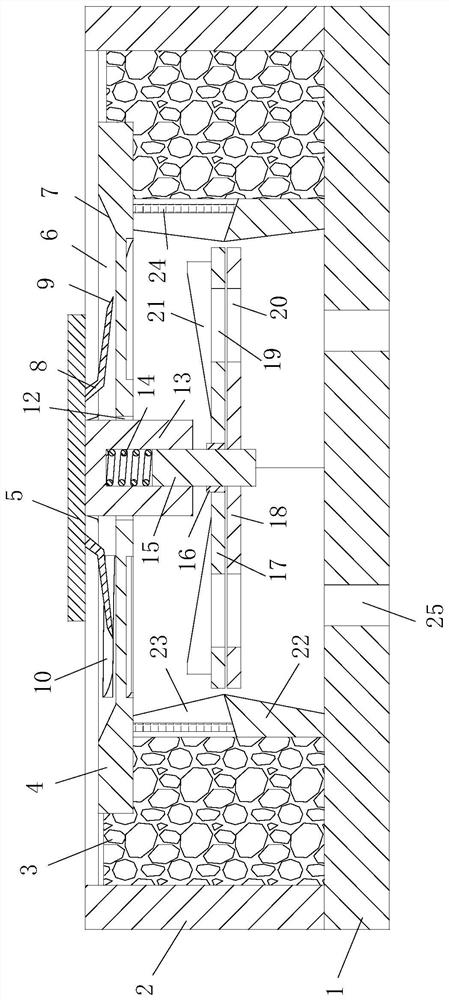

[0034] As a specific embodiment of the present invention, the side wall of the strip groove 6 is provided with a downward spirally extending water inlet hole 10, and the water inlet hole 10 communicates with the strip groove 6 and the inner cavity of the annular support cylinder 22 , the first filter screen 11 matching the water inlet hole 10 is arranged in the strip groove 6 . Since the permeable concrete block 3 is permeable drainage, when the rainfall is large, it will not be able to drain water in time and cause water accumulation on the panel 4. Therefore, through the setting of the water inlet 10, the accumulation of water on the panel 4 can be reduced. It is collected through the strip groove 6 and enters the inner cavity of the annular support cylinder 22 from the water inlet 10, and finally discharged through the drainage hole 25, so that there will be no water accumulation on the road and the risk of urban waterlogging is reduced; the first filter screen 11 is set , ...

specific Embodiment approach

[0038] As a specific embodiment of the present invention, the vertical rod 15 at the upper end of the second disc 18 is provided with a shaft sleeve 16 that can rotate around the vertical rod 15, and the outer side of the shaft sleeve 16 is fixed with the first disc 17 , the radius of the first disc 17 is the same as that of the second disc 18 , and the lower end surface of the first disc 17 is in contact with the upper end surface of the second disc 18 . Since the water inlet hole 10 is helically arranged, the water flow entering from the water inlet hole 10 can impact the first disk 17 and make the first disk 17 rotate around the vertical rod 15 through the shaft sleeve 16, and then the first disk 17 will be rotated by the action of centrifugal force. The accumulated water on the disc 17 is thrown out so that it can better enter the overflow tank 23, which is beneficial to the collection of rainwater.

[0039] As a specific embodiment of the present invention, a torsion spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com