Finite element modeling method for ultrasonic detection of additive manufacturing microstructure

A technology of additive manufacturing and microstructure, applied in instrumentation, geometric CAD, design optimization/simulation, etc., can solve problems such as uneven grain size distribution, scattering attenuation, and structural noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with specific embodiment the present invention is described in further detail:

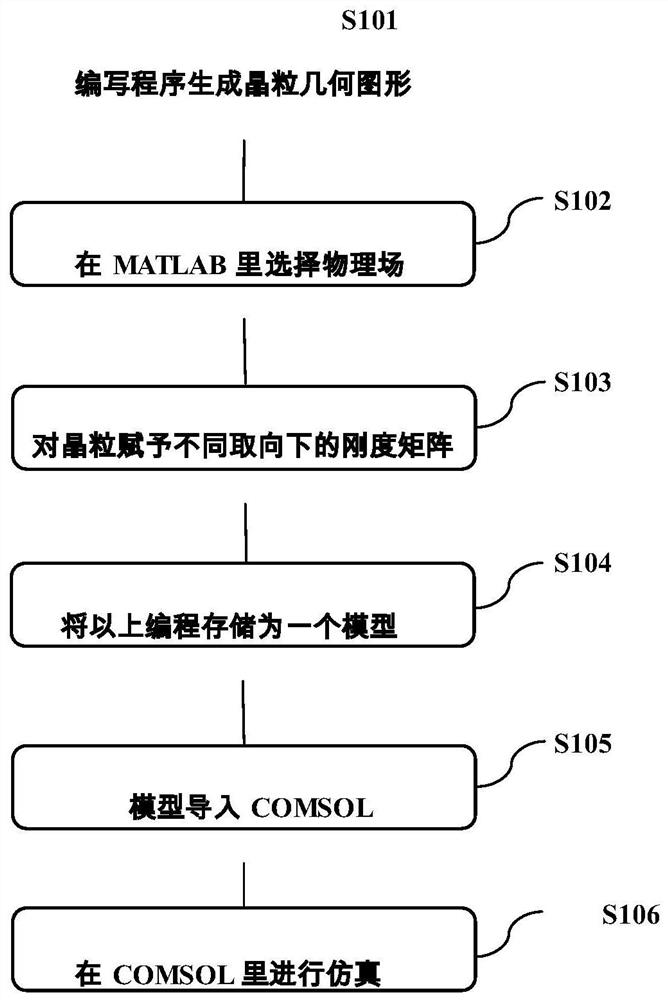

[0040] The present invention aims to propose a finite element model modeling method for ultrasonic detection of microstructures in additive manufacturing. Such as figure 1 As shown, the modeling method includes the following steps:

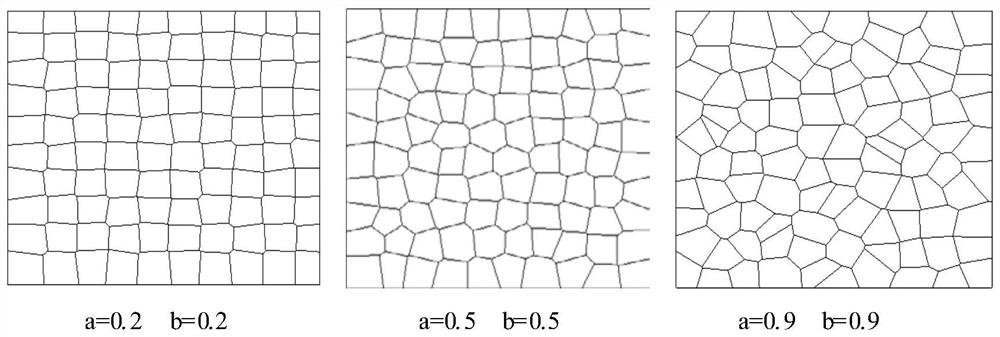

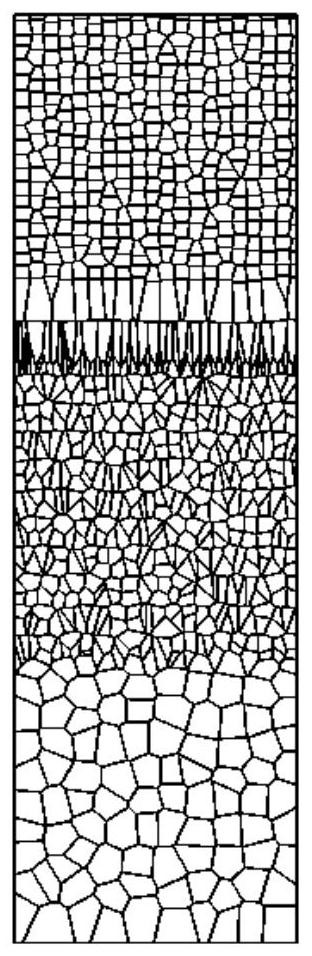

[0041] S101. Establish a geometric model of the microstructure of additive manufacturing, write a program in MATLAB to generate geometric model diagrams of grains in each region, form an overall model through matrix series, and adjust parameters to change the number of grains.

[0042] S102. Select an appropriate physical field, write a program in MATLAB to set the physical field of COMSOL, this time select the physical field interface of solid mechanics.

[0043] S103. Choose different crystal grains as one orientation, select 10 grains in MATLAB, and set the specific orientation information in COMSOL, set according to the above formula,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com