Efficient high-capacity soybean milk machine

A large-capacity soymilk maker technology, applied in milk substitutes, dairy products, food science, etc., can solve the problems that have not been deeply studied on the impact of the filter cartridge and the mixing cavity on the crushing efficiency and effect, so as to improve the crushing efficiency and effect, The effect of reducing the load and reducing the size of the shrinkage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

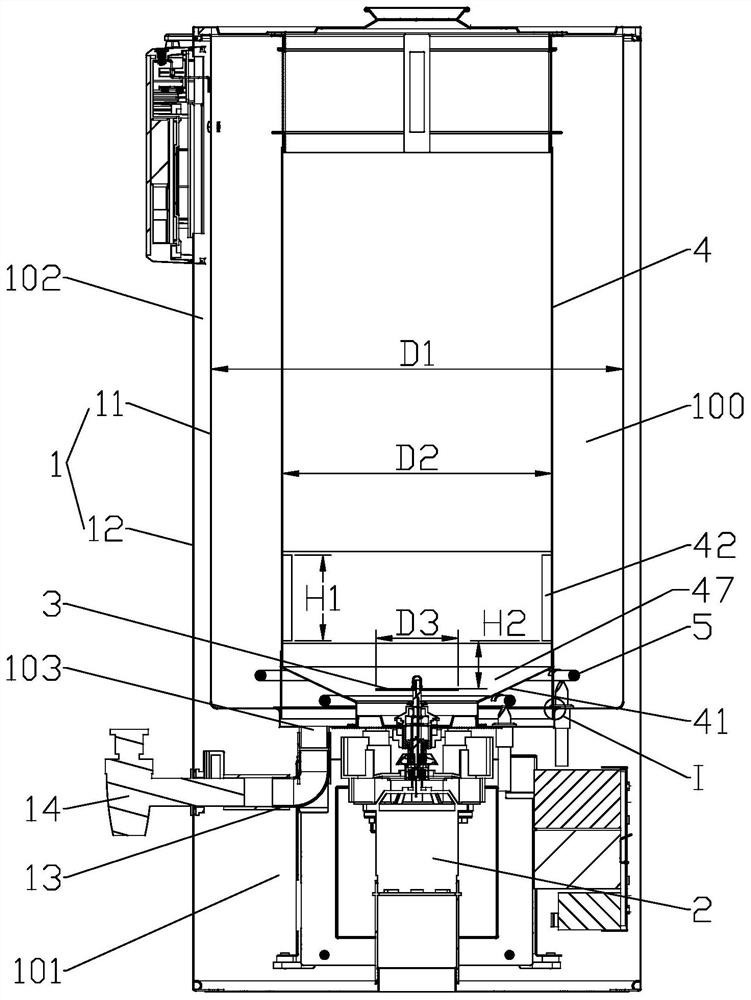

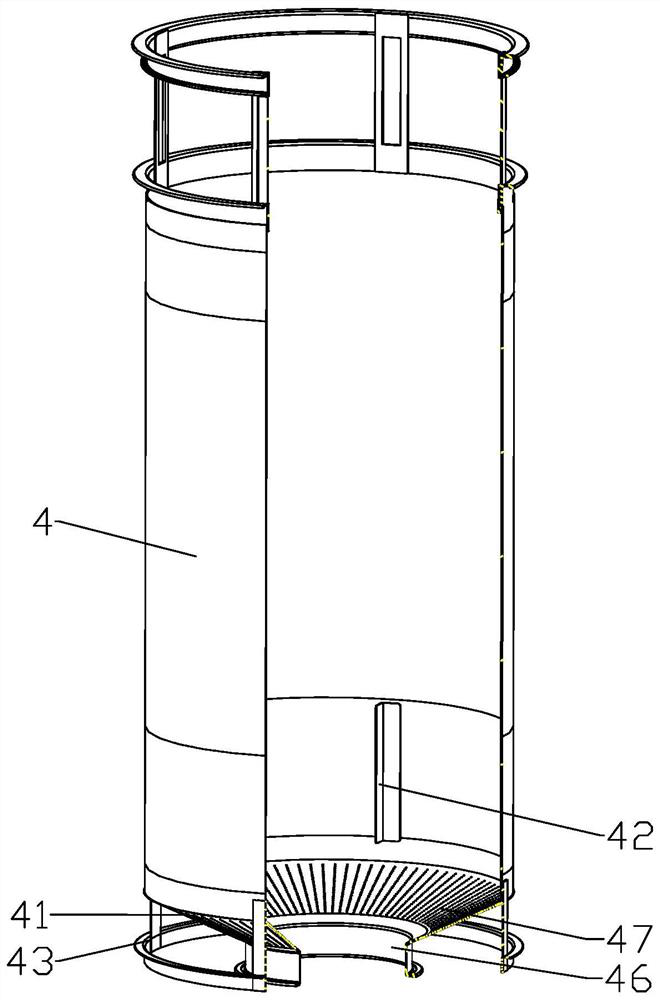

[0024] Such as figure 1 As shown, the present invention provides a large-capacity soybean milk machine, comprising a mixing tank 1, a grinding motor 2 and a grinding blade 3, the mixing tank 1 has a stirring inner chamber 100, the grinding motor 2 is located at the bottom of the mixing tank 1, and the output of the grinding motor 2 The shaft extends into the stirring inner cavity 100, the crushing blade 3 is located in the stirring inner cavity 100 and is installed on the output shaft of the pulverizing motor 2, the stirring inner cavity 100 is provided with a filter cartridge 4, and the bottom end of the filter cartridge 4 is connected to the stirring inner cavity 100 connected to the inner bottom surface of the filter cartridge 4, the crushing blade 3 is located in the filter cartridge 4, the rated capacity of the stirring inner chamber 100 is 40L-50L, the diameter of the stirring inner chamber 100 is D1, the inner diameter of the filter cartridge 4 is D2, the bottom of the f...

Embodiment 2

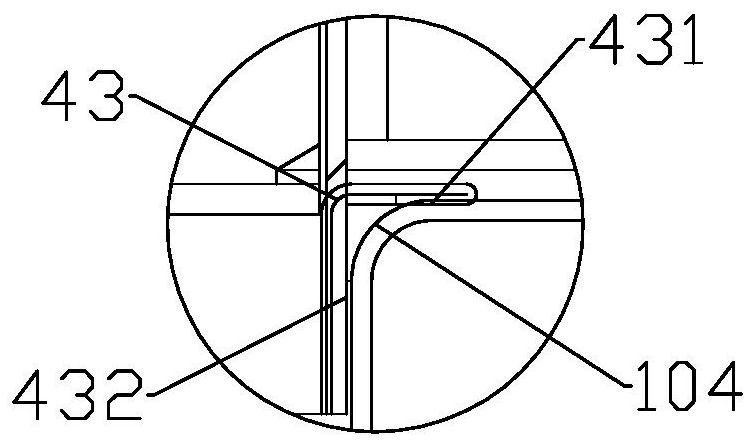

[0037] In addition to the positioning mode of the bottom of a pair of filter cartridges in the embodiment, it can also be as Figure 4 and Figure 5 As shown, the bottom surface of the stirring inner cavity is provided with a mounting frame 5, the mounting frame 5 is provided with an axial positioning surface 51 and a radial limit surface 52, the bottom end of the filter cartridge 4 is provided with a positioning rib 44, and the positioning rib 44 It is clamped under the axial positioning surface 51 , and the radial limiting surface 52 is attached to the outer peripheral side of the filter cartridge 4 . In order to snap the positioning rib 44 under the axial positioning surface 51, it can be mounted in a rotating manner. The axial positioning surface 51 adopts a segmented structure, and a positioning protrusion is arranged between adjacent axial positioning surfaces 51. The ribs 44 pass through the notches 53 , and then the filter cartridge 4 is rotated so that the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com