Light, thin and breathable paper diaper elastic part and production process

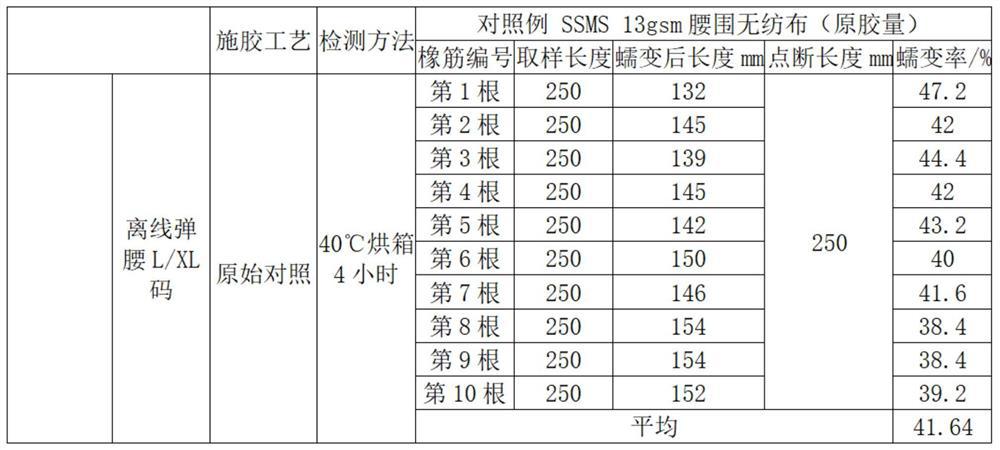

A technology of elastic parts and air-permeable paper, which is applied in the fields of medical science, clothing, underwear, etc., can solve the problems of poor adsorption, uneven distribution of non-woven fabric fibers, and high cost, so as to ensure process stability, reduce the risk of falling pieces, and rubber The effect of low tendon creep rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

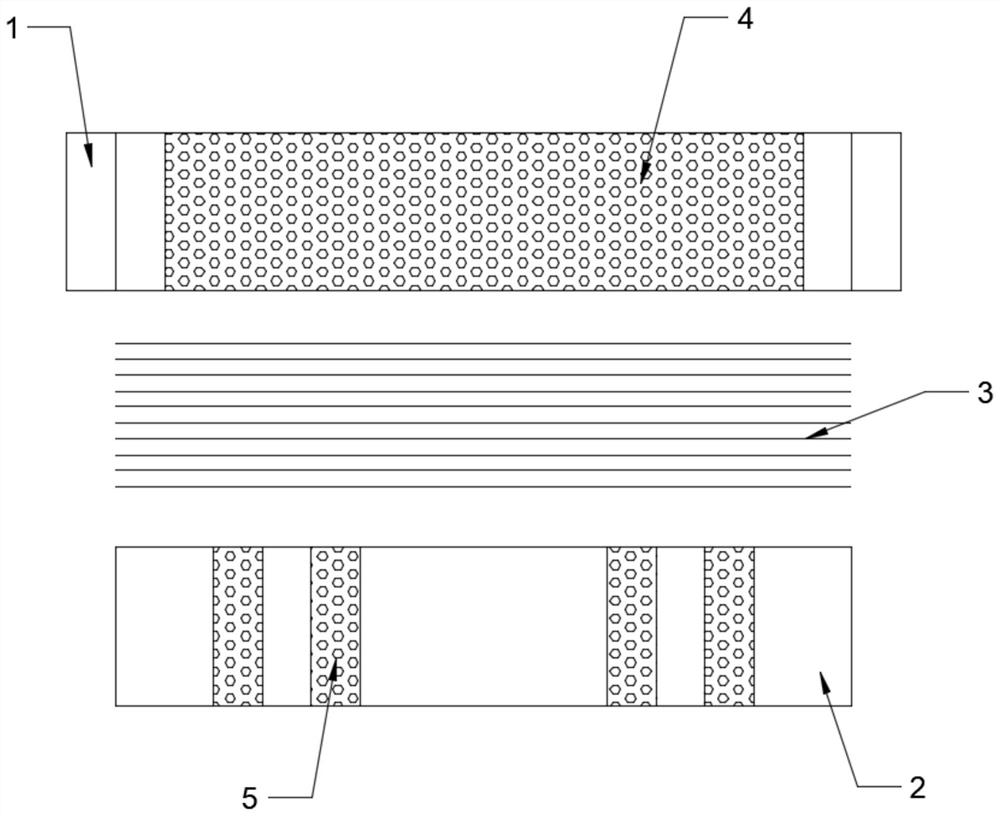

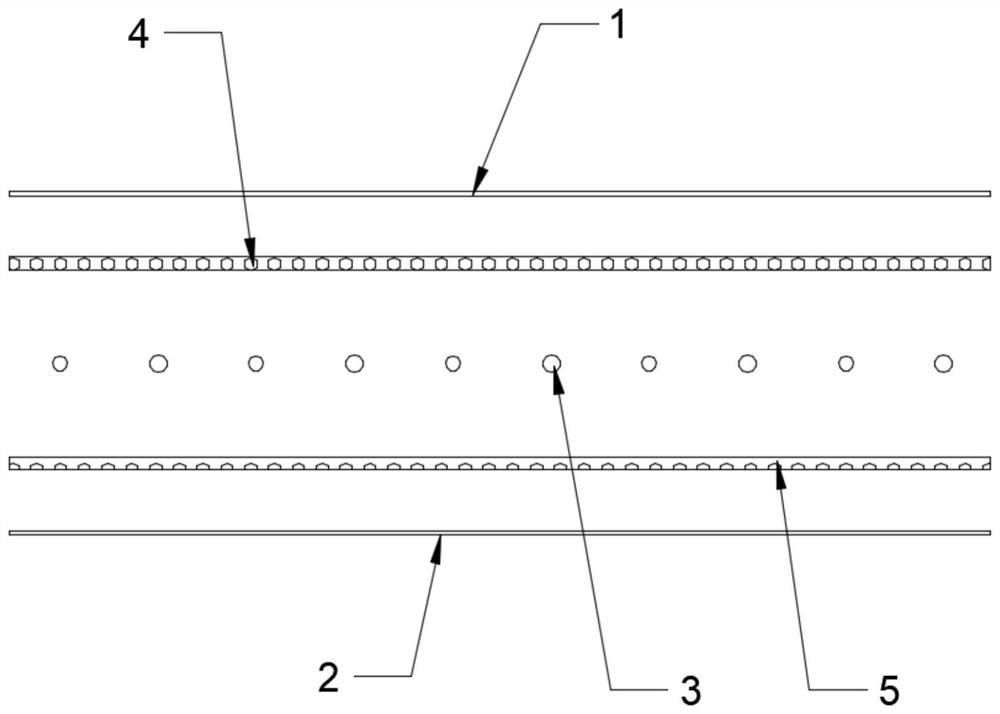

[0027] S1. The upper waistline non-woven fabric is unrolled, and the upper waistline non-woven fabric adhesive machine is used to apply the upper waistline fixing glue through the gap-type coating gun, using a more uniform dot-shaped glue type, and the distance between two adjacent glue points Set it at 2-3mm, the overlapping degree of the glue is 0, the upper waist fixing glue is a continuous squeegee with a width of 250-260mm, and the distance between the squeegee and the two ends of the waist non-woven fabric is about 35-45mm;

[0028] S2. The two ends of the upper waist non-woven fabric are folded by the folding plate at both ends of the upper waist non-woven fabric;

[0029] S3, spandex yarn unwinding, spandex yarn spacing is set to 6.0 ~ 6.5mm, through the spandex yarn tension control mechanism, adjust the spandex yarn stretching ratio, so that the stretching ratio is set at 1.9 ~ 2.1;

[0030] S4. The non-woven fabric for the lower waistline is unrolled, fixed and reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com