A method and system for implementing acoustic tweezers based on spatial Fourier transform

A technology of Fourier transform and implementation method, which is applied in the field of acoustic tweezers based on spatial Fourier transform, can solve the problem of not being able to independently manipulate multiple target objects, and achieve improved flexibility, good effect, and low implementation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

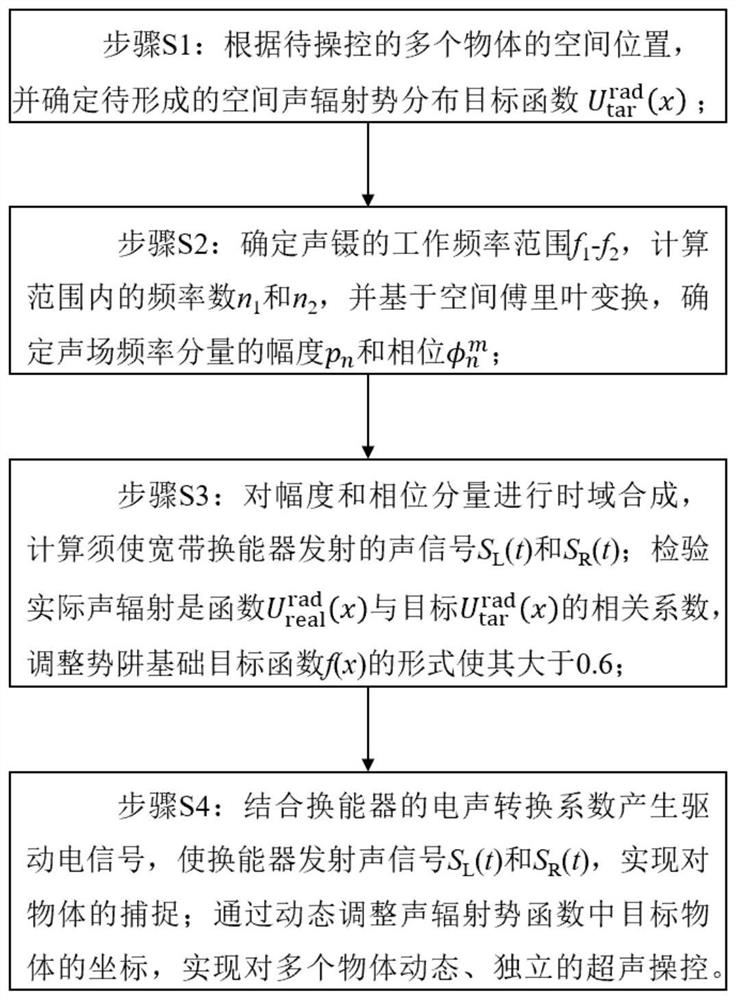

Method used

Image

Examples

Embodiment 1

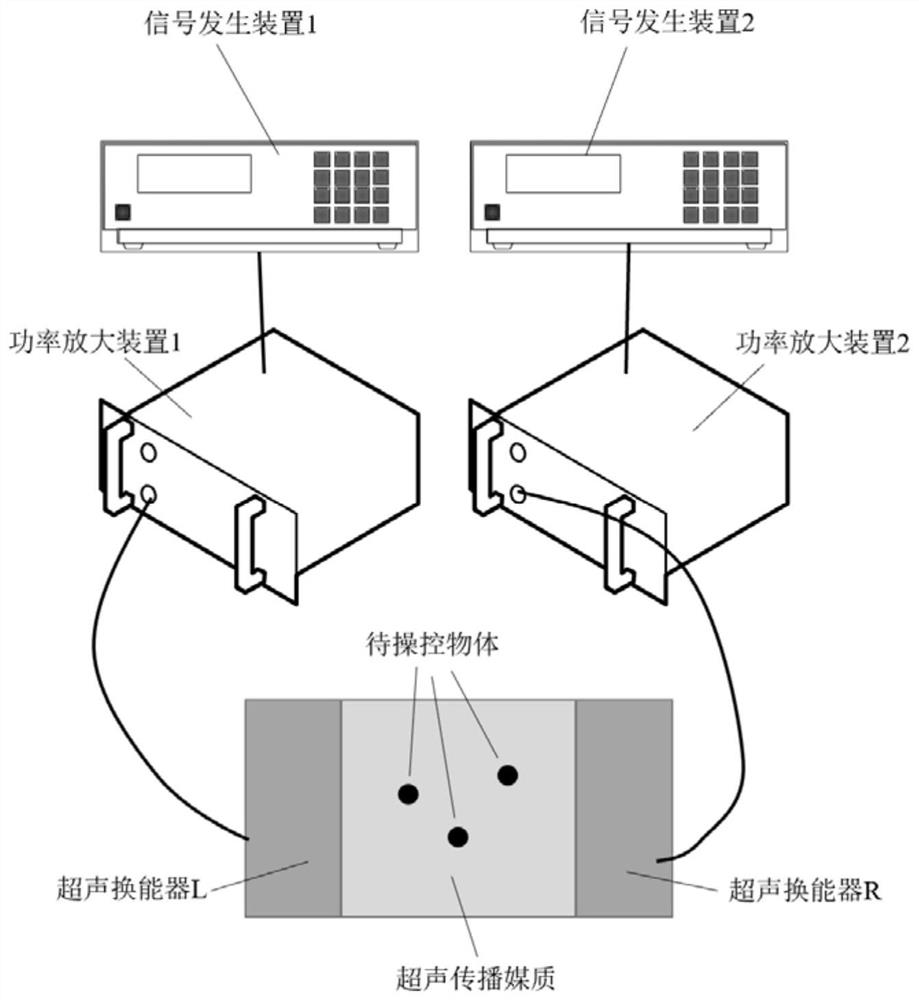

[0060] An acoustic tweezers system based on spatial Fourier transform such as figure 2 As shown, it includes a transducer, an ultrasonic propagation medium and a drive module; the transducer is an ultrasonic transducer, and the two ultrasonic transducers in the system are placed opposite and parallel, and are divided into ultrasonic transducer L and ultrasonic transducer R, the working bandwidth of the two ultrasonic transducers is located at f 1 and f 2 Among them, it is required that within the working bandwidth, the sensitivity of the ultrasonic transducer is not lower than 25% of the highest sensitivity. The ultrasonic propagation medium is arranged between the two ultrasonic transducers, and the ultrasonic propagation medium is fluid, which can be any gas or liquid, such as air or water.

[0061] Ultrasonic transducers can be of different types, including but not limited to piezoelectric ceramic transducers, piezoelectric composite transducers, magnetostrictive transdu...

Embodiment 2

[0102] The content of this embodiment is basically the same as that of Embodiment 1, the difference is that this embodiment implements two independent acoustic potential wells at any designated position, so as to achieve the purpose of capturing the target object at any designated position.

[0103] A pair of parallel broadband interdigital transducers prepared on a Y-X 128° substrate with a thickness of 0.5 mm was selected as the acoustic wave excitation device, and a microfluidic fluid was prepared on the substrate with polydimethylsiloxane (PDMS) as the material. The cavity is filled with water as the fluid medium, and mixed with polystyrene plastic particles with a radius of 5 microns as the object to be manipulated.

[0104] The width of the prepared microfluidic chamber is 2mm, so take l=1mm=1000μm, and the proposed capture position x 1 = 0 μm and x 2 = Polystyrene microparticles around 600 μm so that they form a band respectively.

[0105] In this embodiment, two pote...

Embodiment 3

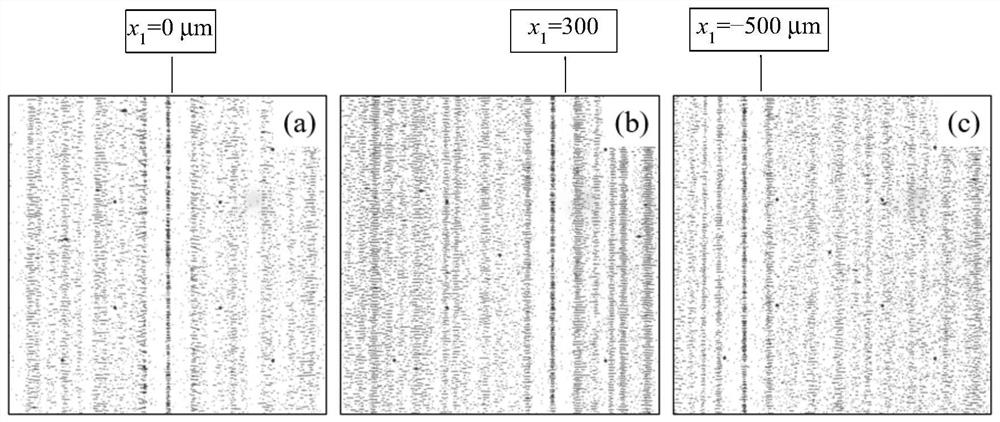

[0111] The content of this embodiment is basically the same as that of Embodiment 1, the difference is that this embodiment implements three independent acoustic potential wells at any designated position, so as to achieve the purpose of capturing the target object at any designated position.

[0112]In this embodiment, a pair of parallel broadband interdigital transducers prepared on a Y-X 128° substrate with a thickness of 0.5 mm is selected as the acoustic wave excitation device, and polydimethylsiloxane (PDMS) is used as the material on the substrate to prepare A microfluidic chamber is filled with water as the fluid medium, and polystyrene plastic particles with a radius of 5 microns are mixed as objects to be manipulated.

[0113] The width of the prepared microfluidic chamber is 2mm, so take l=1mm=1000μm, and the proposed capture position x 1 = -180μm, x 2 = 0 μm, x 3 = Polystyrene particles around 180μm, so that they form a strip respectively, and move x 2 = 0, whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com