Waste plastic bottle treatment device capable of cleaning interior and suitable for different shapes

A processing device and plastic bottle technology, applied in the field of plastics, can solve problems such as difficult cleaning, heavy dirt, and high manual cleaning work intensity, and achieve the effect of reducing work intensity, reducing clamping area, and improving cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

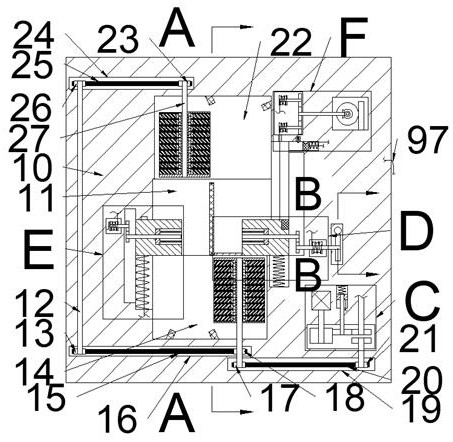

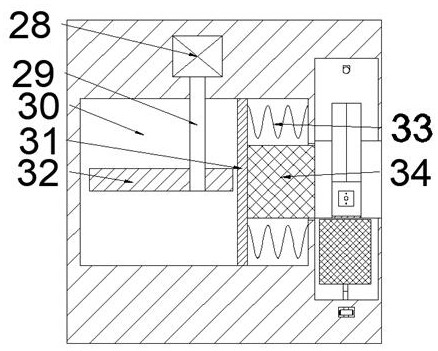

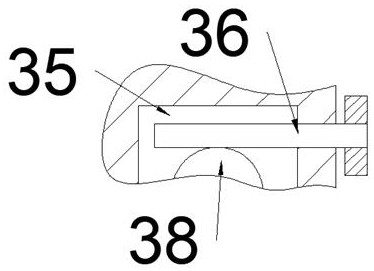

[0022] Combine below Figure 1-7 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0023] A waste plastic bottle processing device that can clean the interior and is suitable for different shapes described in conjunction with accompanying drawings 1-7 includes a main box body 10, and a cutting cavity 11 is arranged inside the main box body 10. On the cutting cavity 11 The side is connected with an upper cleaning chamber 22, and the lower side of the cutting chamber 11 is connected with a lower cleaning chamber 14. The lower side of the lower cleaning chamber 14 is provided with a linkage belt chamber 16, and the lower side of the linkage belt chamber 16 is provided with a cleaning chamber. Belt cavity 19, the upper end wall of the cleaning belt cavity 19 is rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com