Vertical steel wire net rack insulation board forming machine

A technology for steel wire mesh frame and plate forming machine, which is applied in thermal insulation, building components, applications, etc., can solve the problems of aging of rubber rings, inability to produce, limited production size, etc., and achieves stable and stable structure, easy maintenance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] First of all, those skilled in the art should understand that the embodiments described here are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

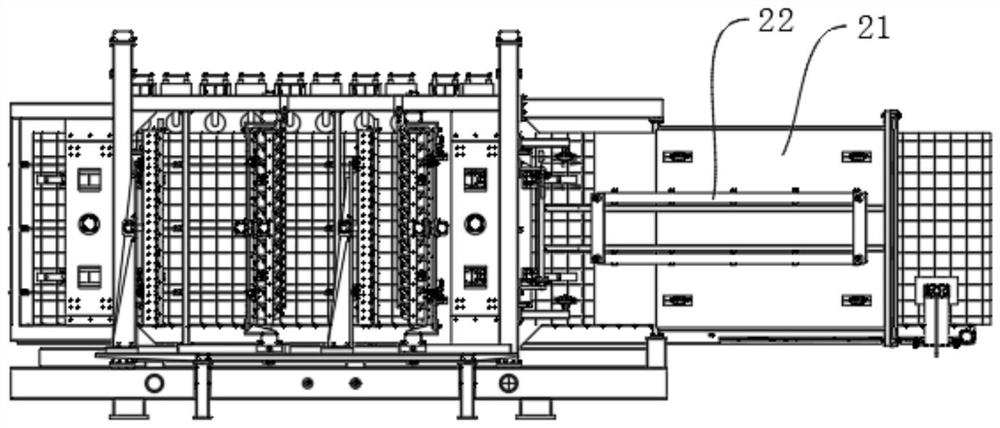

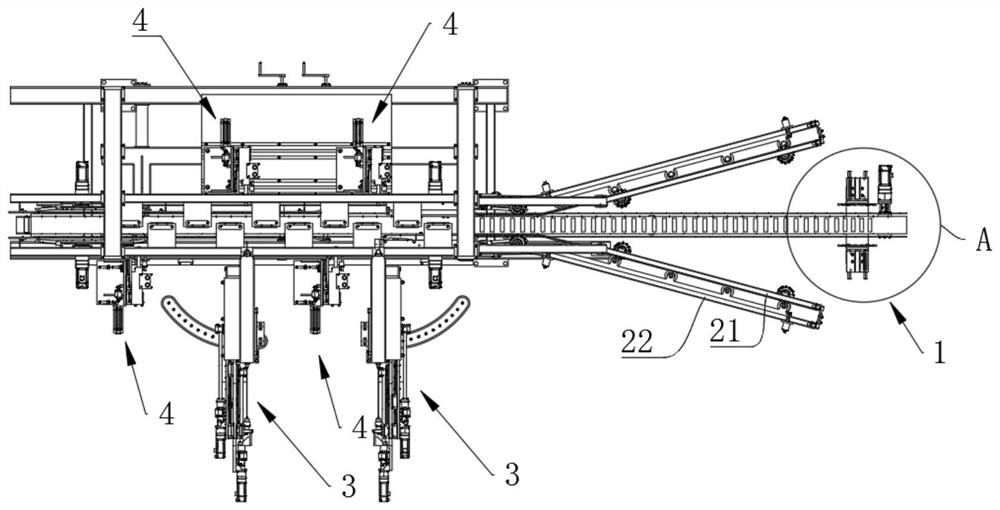

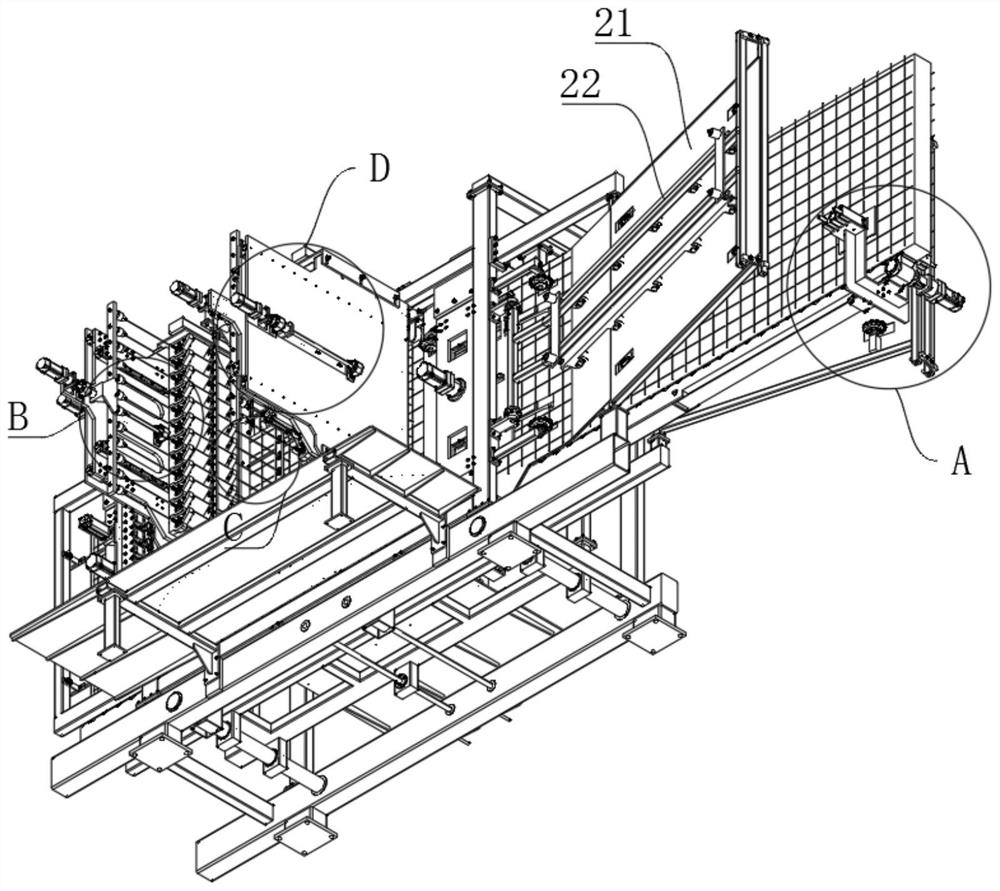

[0024] see Figure 1 to Figure 3 , image 3 It is an isometric view from the perspective of looking up. The present invention proposes a vertical steel wire grid insulation board molding machine, which is used to produce steel wire mesh insulation boards, which includes a support frame, a conveying device 1, a wire insert Device 3, welding device 4. The support frame stands on the ground and is used to connect and support various devices. The conveying device 1 , the wire inserting device 3 and the welding device 4 are all fixedly connected with the support frame. The design and structure of the support frame are completely in the prior art, and there are many structural styles and connection methods of metal plates, metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com