High-transparency easy-to-open barrier film

An easy-to-open and barrier film technology, which is applied in the field of polymers, can solve the problems of transparency and easy-to-open, surface sticking and melting, etc., achieve good transparency and easy-to-open, reduce friction coefficient and bond Resistance, effect of increasing affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

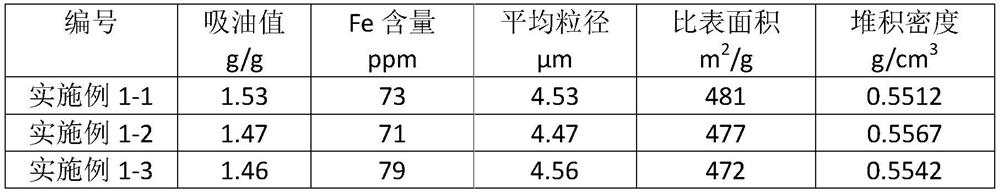

Embodiment 1

[0031] A highly transparent and easy-to-open barrier film, including a first PE film layer, a first adhesive layer, a PEN film layer, a second adhesive layer, a barrier layer, and a third adhesive layer arranged sequentially from inside to outside in a co-extruded manner. Layer, PEI film layer, the fourth adhesive layer and the second PE film layer, the first PE film layer is composed of low-density polyethylene, metallocene linear low-density polyethylene, Composed of high-density polyethylene, silicon-aluminum film opening agent; the second PE film layer is composed of low-density polyethylene, medium-density polyethylene, and silicon-aluminum film opening agent with a mass ratio of 17:2:1.

[0032] Wherein, the silicon-aluminum film opening agent is prepared by the following method:

[0033] At a temperature of 30°C, inject 50L of bottom water and 45 moles of aluminum sulfate into the stirred reaction vessel. After the aluminum sulfate is completely dissolved, add sulfuric ...

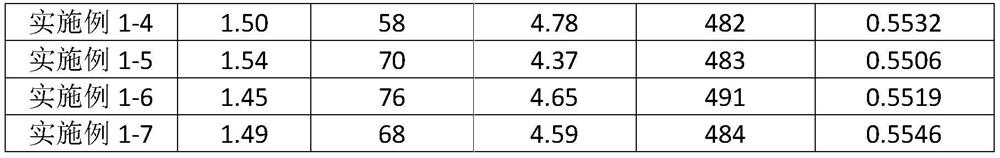

Embodiment 2

[0039] A highly transparent and easy-to-open barrier film, including a first PE film layer, a first adhesive layer, a PEN film layer, a second adhesive layer, a barrier layer, and a third adhesive layer arranged sequentially from inside to outside in a co-extruded manner. Layer, PEI film layer, the fourth adhesive layer and the second PE film layer, the first PE film layer is composed of low-density polyethylene, metallocene linear low-density polyethylene, Composed of high-density polyethylene, silicon-aluminum film opening agent; the second PE film layer is composed of low-density polyethylene, medium-density polyethylene, and silicon-aluminum film opening agent with a mass ratio of 17:2:1.

[0040] Wherein, the silicon-aluminum film opening agent is prepared by the following method:

[0041]At a temperature of 60°C, inject 50L of bottom water and 15 moles of aluminum nitrate into the stirred reaction vessel. After the aluminum nitrate is completely dissolved, add sulfuric a...

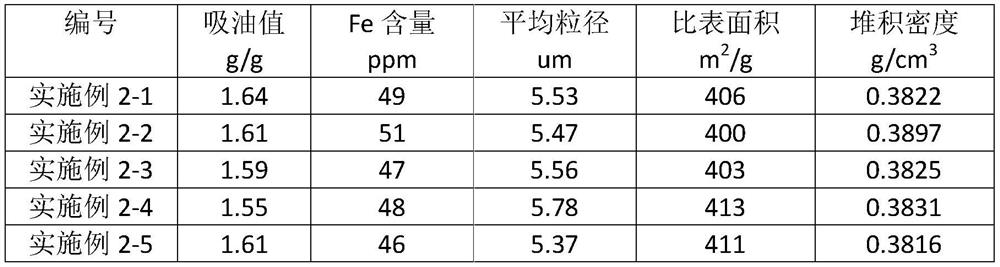

Embodiment 3

[0046] A highly transparent and easy-to-open barrier film, including a first PE film layer, a first adhesive layer, a PEN film layer, a second adhesive layer, a barrier layer, and a third adhesive layer arranged sequentially from inside to outside in a co-extruded manner. Layer, PEI film layer, the fourth adhesive layer and the second PE film layer, the first PE film layer is composed of low-density polyethylene, metallocene linear low-density polyethylene, Composed of high-density polyethylene, silicon-aluminum film opening agent; the second PE film layer is composed of low-density polyethylene, medium-density polyethylene, and silicon-aluminum film opening agent with a mass ratio of 17:2:1.

[0047] Wherein, the silicon-aluminum film opening agent is prepared by the following method:

[0048] At a temperature of 40°C, inject 50L of bottom water and 30 moles of aluminum chloride into the stirred reaction vessel, and after the aluminum chloride is completely dissolved, add sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com