Energy-saving and environment-friendly isolated heat dissipation charging pile

An energy saving, environmental protection, charging pile technology, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems affecting the normal use of charging piles, energy consumption, etc., and achieve the effect of strong adaptability and accelerated heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

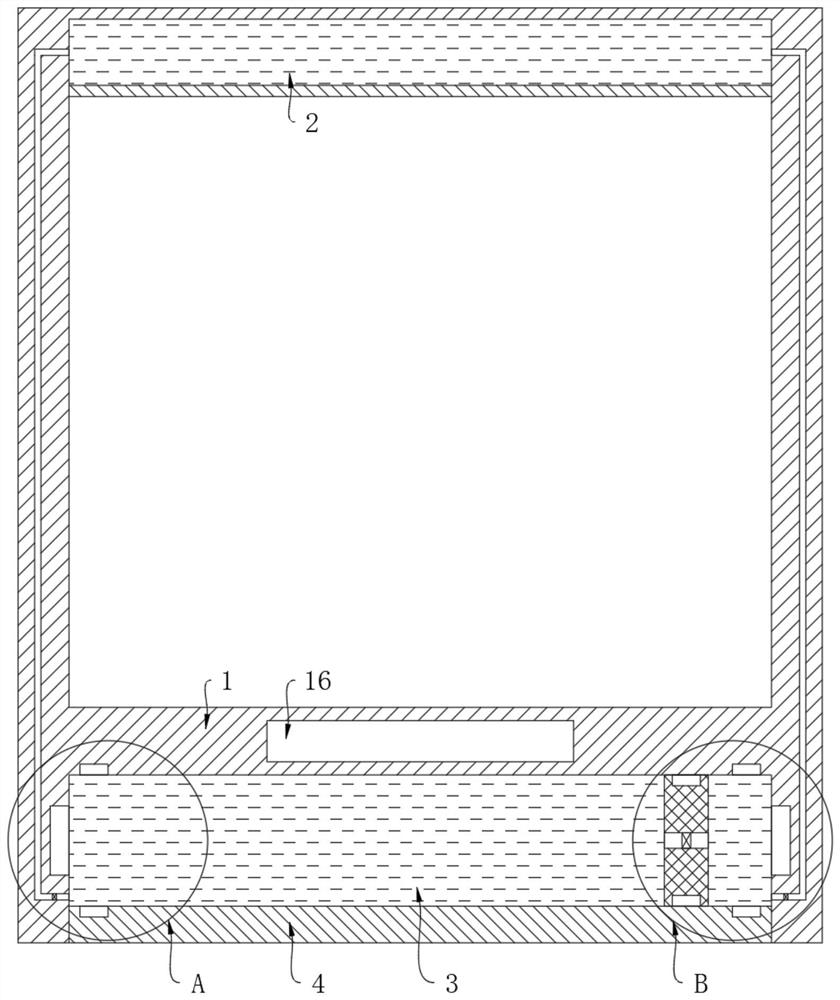

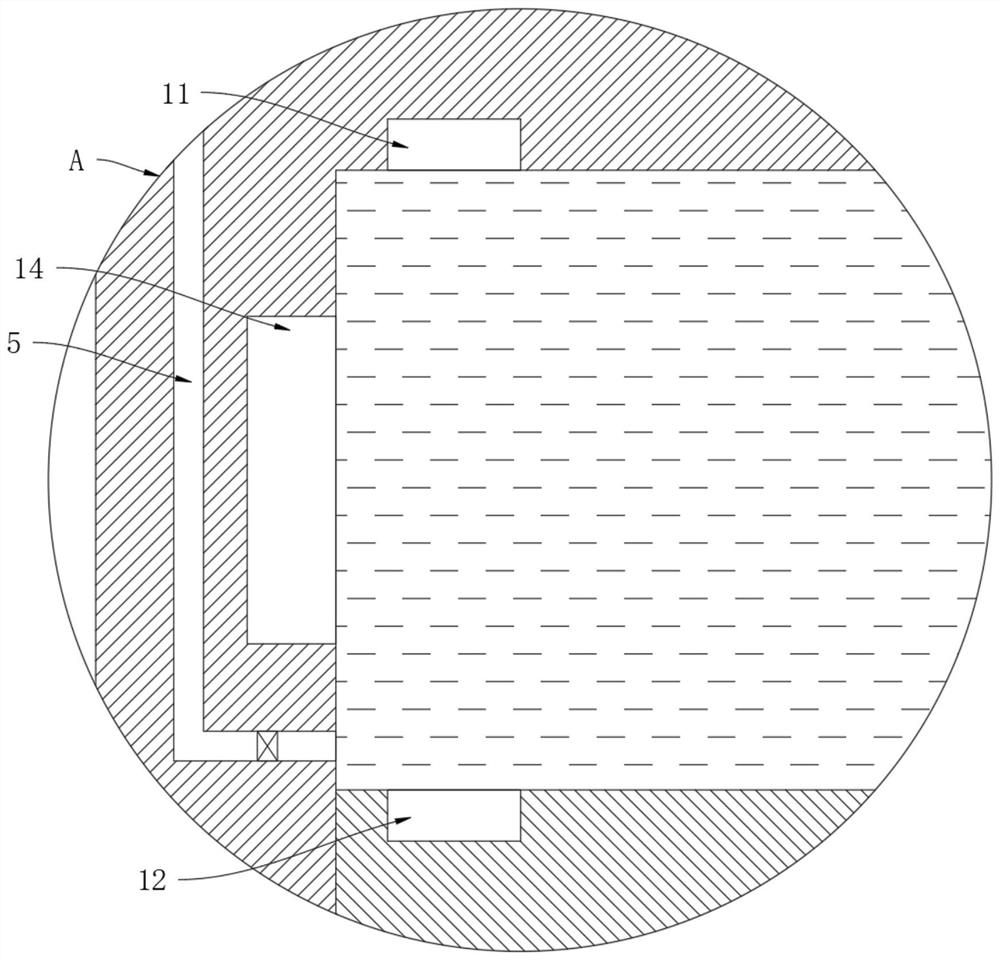

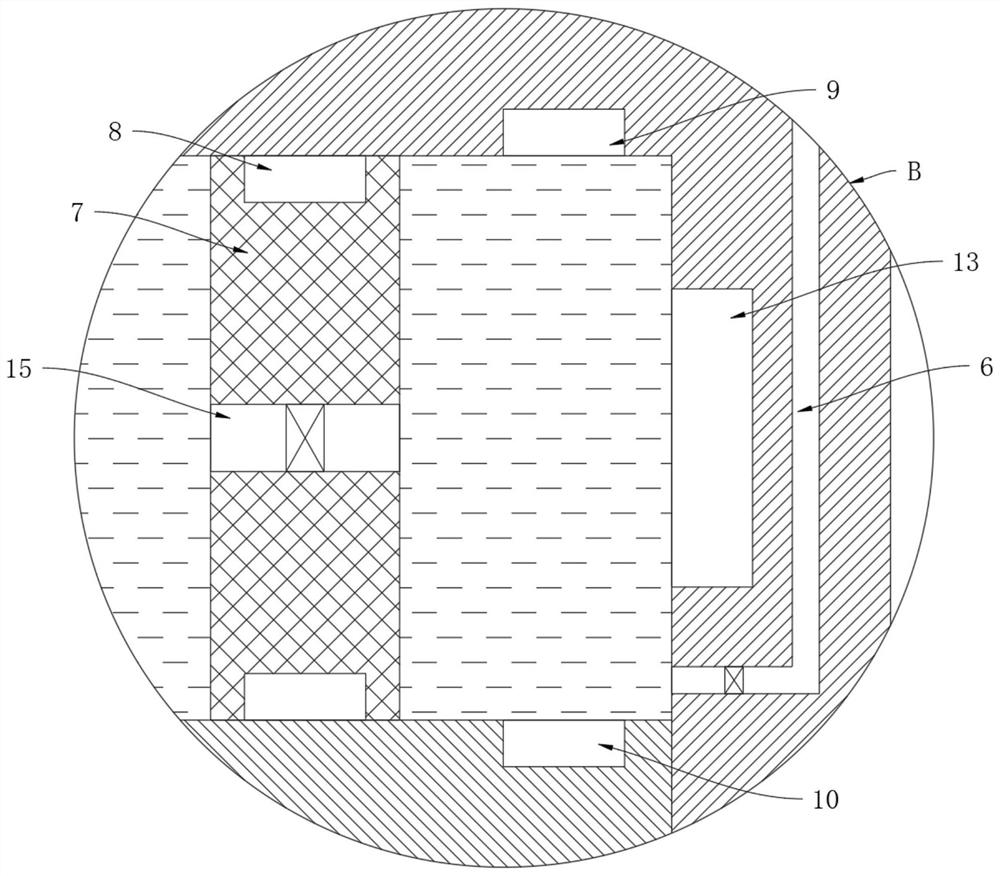

[0024] refer to Figure 1-4 , an energy-saving and environment-friendly isolated heat dissipation charging pile, comprising a hollow charging pile body 1, the inner top wall and the lower end surface of the charging pile body 1 are respectively provided with a heat absorption groove 2 and a cooling groove 3, and the heat absorption groove 2 and the cooling groove The notches of the groove 3 are sealed and fixedly connected with the heat conducting plate 4, the heat-absorbing groove 2 and the cooling groove 3 are filled with cooling liquid, and the cooling groove 3 is vertically sealed and slidingly connected with a magnetic piston 7, and the magnetic piston 7 moves the cooling groove 3. It is divided into a driving area and a driven area. A connecting pipe 15 connecting the driving area and the driven area is provided on the magnetic piston 7. A first one-way valve is installed in the connecting pipe 15. The first one-way valve only allows the driving area to The internal gas ...

Embodiment 2

[0030] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that the lower end surface of the heat conduction plate 4 at the lower end surface of the charging pile body 1 is symmetrically provided with placement grooves 17, and each placement groove 17 is installed with a plurality of Fan blades 18, and coil springs are elastically connected between each rotating shaft and the placement groove 17, winding rollers 19 are interference-fitted on the rotating shafts, and traction wires are fixedly connected between both sides of the magnetic piston 7 and the winding rollers 19 , The charging pile body 1 is provided with a slideway for the traction line to slide, and a sealing rubber is provided between the slideway and the traction line, so as to avoid leakage of the coolant in the cooling tank 3 .

[0031]This embodiment can illustrate its functional principle through the following operation mode: when the magnetic piston 7 in the cooling tank 3 moves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com