Remote automatic core changing and sealing real-time monitoring coiled tubing blowout prevention box

A real-time monitoring and coiled tubing technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problem of too few sealing structures of the blowout preventer, and protect the blowout preventer and operators, The effect of convenient maintenance and replacement and simplified replacement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to following description:

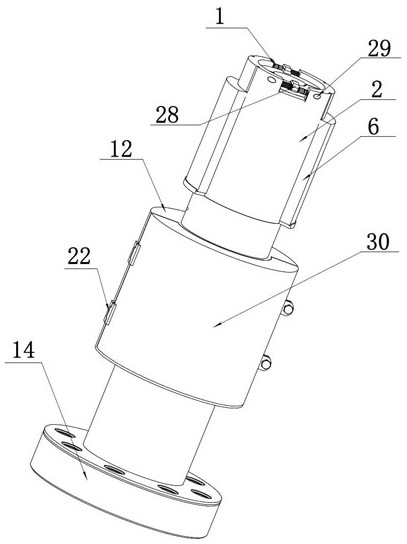

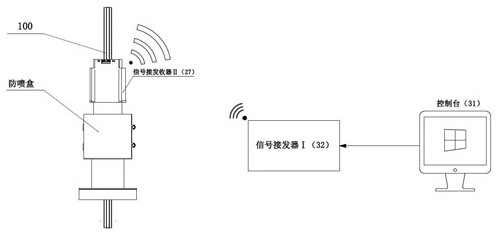

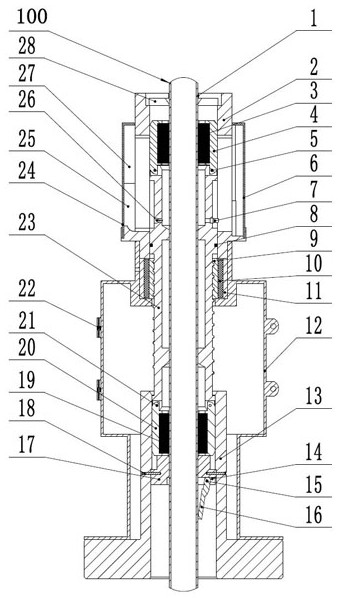

[0039] Such as Figure 1-Figure 13 Shown: a coiled tube blowout preventer with remote automatic core replacement and sealing real-time monitoring consists of an upper casing 2, a torsion spring I1, an upper cover 28, a pin I29, a baffle I6, a baffle II 24, a pressure sensor 26, and an upper plug Mechanism, wireless electromagnetic wave control system, stepping servo hollow shaft motor, coaxial drive sliding sleeve 23, sealing ring 8, pressurized gas nozzle 7, lower sealing mechanism, outer shell I12, outer shell II30, connecting flange 13, inside the well It consists of a fluid blocking mechanism; the upper blocking mechanism is composed of an upper extrusion block 4, a pin II 5, and a sealing rubber core I 3; the wireless electromagnetic wave control system consists of a console 31, a signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com