Self-resetting single-valve main and auxiliary piston hydraulic drive device and method for pushrod engine

A driving device and self-resetting technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of reduced reliability, system complexity, and the inability to take into account the automatic adjustment function of the engine driving function at the same time. The effect of simplifying the overall installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

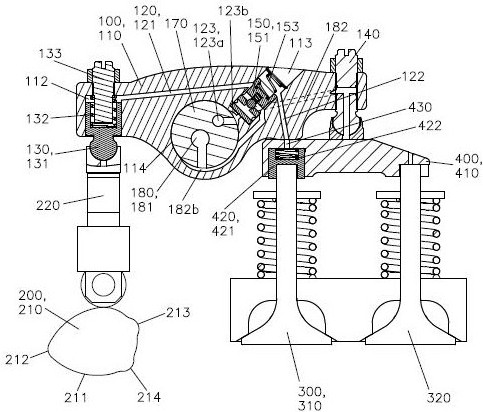

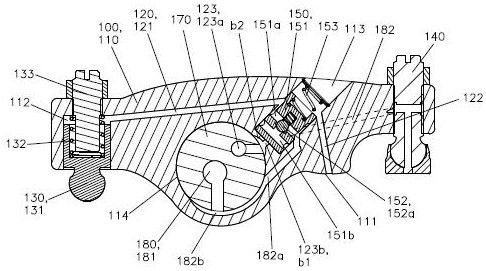

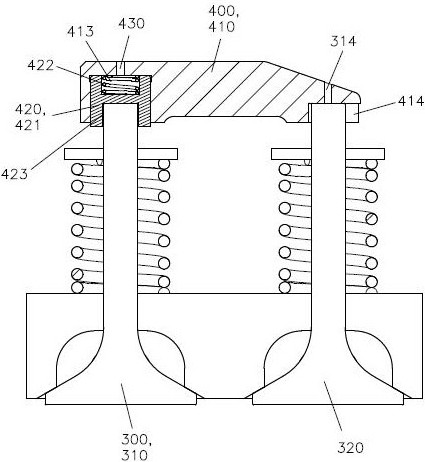

[0092] Such as Figure 1-10 The hydraulic drive device for a self-resetting single-valve main and auxiliary piston for a push rod engine shown includes a rocker arm assembly 100, an integrated cam and push rod assembly 200, an exhaust valve group 300, a valve bridge assembly 400 and a limit assembly 500, The rocker arm assembly 100 includes a rocker arm shaft 170, a rocker arm body 110 and a drive oil circuit 120, the rocker arm shaft 170 is arranged in the rocker arm shaft hole 114, the rocker arm body 110 is rotatably mounted on the rocker arm shaft 170, and the rocker arm body 110 One end is provided with driving main piston 130, and the other end is provided with first elephant foot assembly 140, and driving main piston 130 comprises main piston body 131, and one end of rocking arm body 110 is provided with main piston hole 112, and main piston hole 112 is connected with main piston. The oil passage 121 communicates, and the main piston body 131 is coaxially and slidably a...

Embodiment 2

[0113] Such as Figure 11 Compared with Embodiment 1, the illustrated embodiment 2 differs only in that the auxiliary piston oil passage 122 communicates with the first elephant foot assembly 140, and the valve bridge body 410 is provided with an inner connection passage 411, and the first elephant foot assembly 140 communicates with the driving auxiliary piston 420 through the inner connecting channel 411 , and when the limiting surface 111 is set in contact with the valve bridge body 410 , the limiting surface 111 seals the oil drain channel 430 .

[0114] When the auxiliary piston oil passage 122 passes through the first elephant foot assembly 140, the lubricating oil passage 180 includes a rocker shaft lubricating oil passage 181 and a spray lubricating oil passage 183, and the rocker shaft lubricating oil passage 181 is opened on the rocker shaft 170 , the spray lubricating oil passage 183 is opened on the rocker arm body 110, which includes a spray lubricating section 183a...

Embodiment 3

[0116] In order to reduce the height of the rocker arm assembly 100 on the side of the integrated cam and push rod assembly 200, as Figure 12 Compared with Embodiment 1, the illustrated embodiment 3 differs only in that: the auxiliary piston oil passage 122 is communicated with a second elephant foot assembly 160, and the second elephant foot assembly 160 is arranged on the rocker arm body 110, and Located directly above the oil drain passage 430, the second elephant foot assembly 160 can be threaded or fixedly arranged on the rocker arm body 110 in the present invention. When the lower end of the second elephant foot assembly 160 contacts the valve bridge body 410, the second elephant foot assembly 160 Two elephant foot assemblies 160 are communicated with the oil drain passage 430, and the second elephant foot assembly 160 used in the present embodiment is an existing rocking arm elephant foot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com