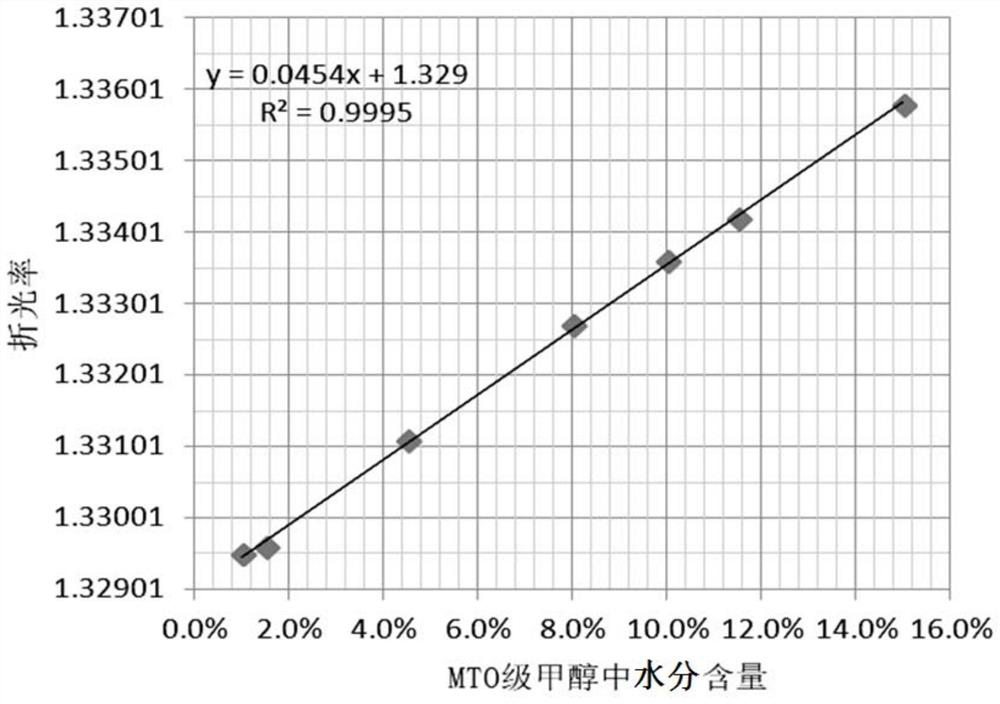

Method for rapidly determining moisture content in MTO-grade methanol by using refraction method

A technology of refraction and methanol, which is applied to the measurement of phase influence characteristics, etc., can solve problems such as difficulty in moisture content, and achieve the effects of reducing energy consumption, shortening analysis time, and simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0060] Example 1 spike experiment

[0061] Instrument: Anton Paar Abbemat 650 refractometer;

[0062] Sample and experimental operation:

[0063] 1) Add 2g of high-purity water to the prepared MTO grade methanol (methanol-water mixed solution) with a water content of 1.5%, so that the theoretical water content is 3.43%, and the result measured with a refractometer is 1.3307, calculated according to the standard curve The moisture content is 3.40%;

[0064] 2) Add 2g of high-purity water to the prepared MTO grade methanol (methanol-water mixed solution) with a water content of 8.0%, so that the theoretical moisture content is 9.80%, and the result measured with a refractometer is 1.3335, calculated according to the standard curve The moisture content is 9.78%.

example 2

[0065] Example 2: Comparative test of MTO grade methanol and superior grade pure methanol

[0066] 1) Take the prepared MTO grade methanol solution with a theoretical moisture content of 3.43% and 9.80% as a comparison sample; take superior grade pure methanol (see Table 4), and prepare a mixed solution with a water content of 3.43% and 9.80% respectively , the data measured with a refractometer are shown in Table 3:

[0067] Table 3. Refractive Index Measured Using MTO Grade Methanol and Premium Pure Methanol

[0068] Water content 3.43% Water content 9.80% MTO grade methanol solution 1.3307 1.3335 Premium pure methanol solution 1.3307 1.3336

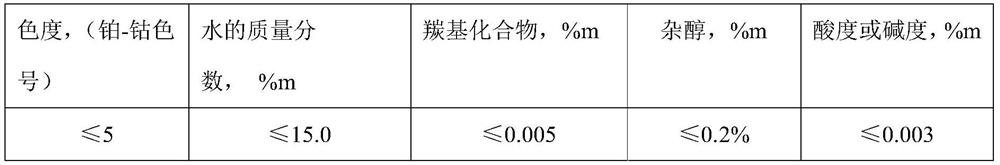

[0069] Table 4. Physical and chemical indicators of superior pure methanol

[0070] Chroma, (platinum-cobalt color number) Mass fraction of water, %m Carbonyl compounds, %m Acidity or Alkalinity, %m ≤5 <0.01 ≤0.0005 ≤0.0004

example 3

[0071] Example 3: Determination of Moisture Content in MTO Grade Methanol Using a Karl Fischer Moisture Analyzer

[0072] 1) Instruments and samples

[0073] Instrument: Mettler V20 volumetric moisture meter;

[0074] Reagent: Tianjin Siyou volumetric Karl Fischer reagent;

[0075] Sample: Take prepared MTO grade methanol with water content of 1.5% and 8.0%.

[0076] 2) Measurement steps

[0077] The above samples and reagents were added to the Karl Fischer moisture meter, and the measurement results are shown in Table 5:

[0078] Table 5. Determination results using volumetric Karl Fischer moisture meter

[0079] 1.5% water sample 8.0% water sample Measured moisture content, %m 1.508% 8.011%

[0080] 6. Analysis of experimental results

[0081] For instance 1

[0082] The invention adds a known amount of water to the MTO grade methanol, calculates the theoretical water content, and compares the water content measured by a refractometer with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com