Optical fiber device for point-ring-shaped laser output and preparation method thereof

A technology for outputting optical fibers and optical fiber devices, which is applied in the field of optical fiber devices output by point-ring laser and its preparation, can solve the problems of complex shaping structure, unfavorable high integration, poor overall reliability of spatial structure, etc., and achieves optical adaptation surface width and threshold value high power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

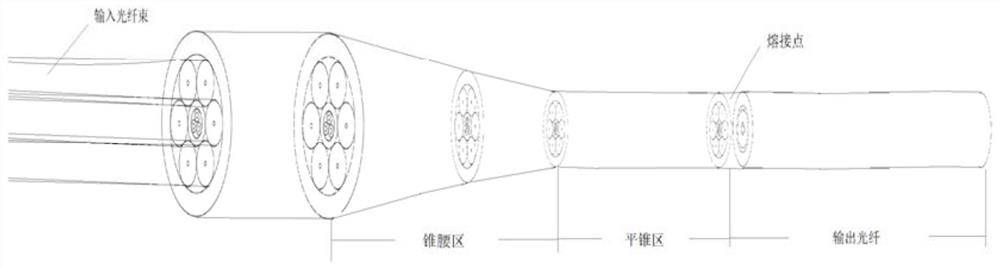

[0067] The preparation method of the optical fiber device for the above-mentioned spot ring laser output comprises the following steps:

[0068] 1) Design the size of the input fiber bundle material according to the actual size of the output fiber, and determine the parameters of the inner input fiber bundle, the inner low refractive index sleeve, the outer input fiber bundle, and the outer low refractive index sleeve, including the quantity , inner diameter, outer diameter, and length; cut off several optical fibers of a certain length, strip off the coating layer of the tail fiber by 15cm, pre-process the input fiber bundle by laser etching, chemical corrosion or other physical methods, and adjust the input fiber bundle The diameter D2 of the cladding is within the design range, and the length of the fiber after pretreatment is greater than 10cm, or directly use the fiber that meets the parameters of the core and cladding diameters prepared by the drawing tower;

[0069] 2) ...

Embodiment 1

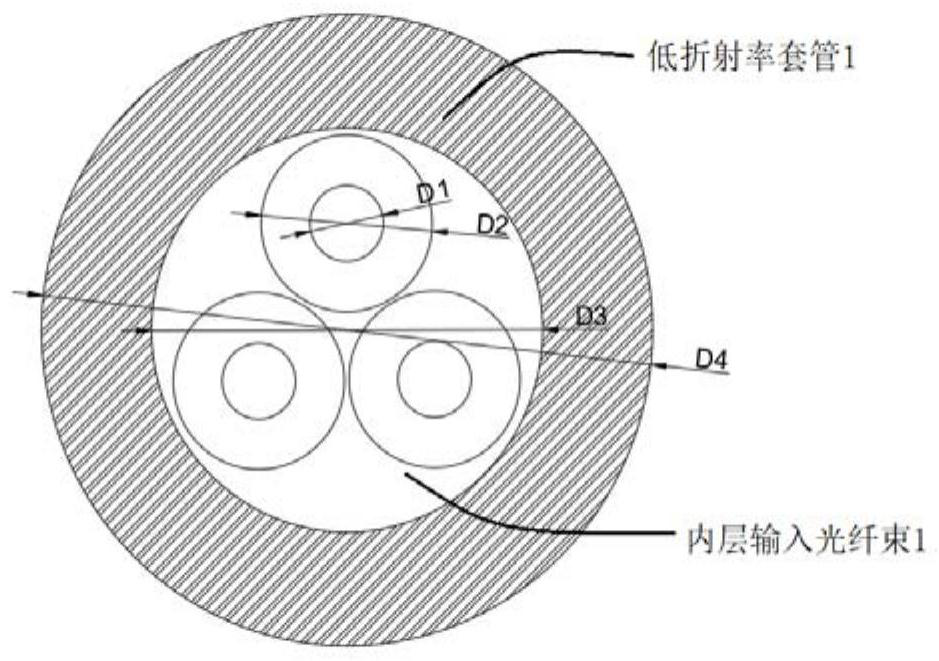

[0080] The inner layer input fiber bundle is selected as core / cladding: 20 / 400um, NA: 0.06 / 0.46 fiber double cladding; fiber pretreatment to cladding diameter D2: 70um;

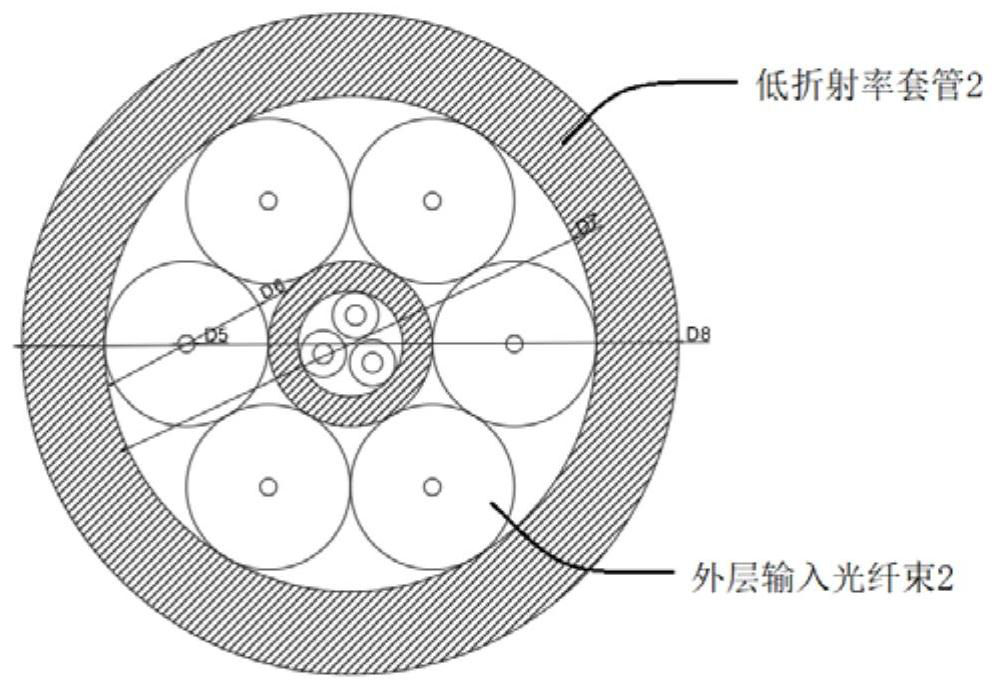

[0081] The outer layer input fiber bundle uses core / cladding: 30 / 250um, NA: 0.06 / 0.46 fiber double cladding; the outer layer input fiber bundle does not do pretreatment;

[0082] The inner diameter D3 of the inner low refractive index sleeve is 160um, the outer diameter D4 is 250um; the inner diameter of the outer low refractive index sleeve is D7 = 760um, and the outer diameter is D8 = 900um;

[0083] The core diameter of the output fiber is D.A=70um, and the cladding thicknesses are: d.B=15um, d.C=100um, d.D=20um, d.E=10um.

[0084] According to the above materials and the above-mentioned production method, the bundle tapers are assembled. Considering the collapse of the middle of the optical fiber bundle assembly during the taper process, the diameter of the sleeve flat taper after the taper is actually co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com