Effective magnetic potential calculation method for permanent magnet magnetic coupler

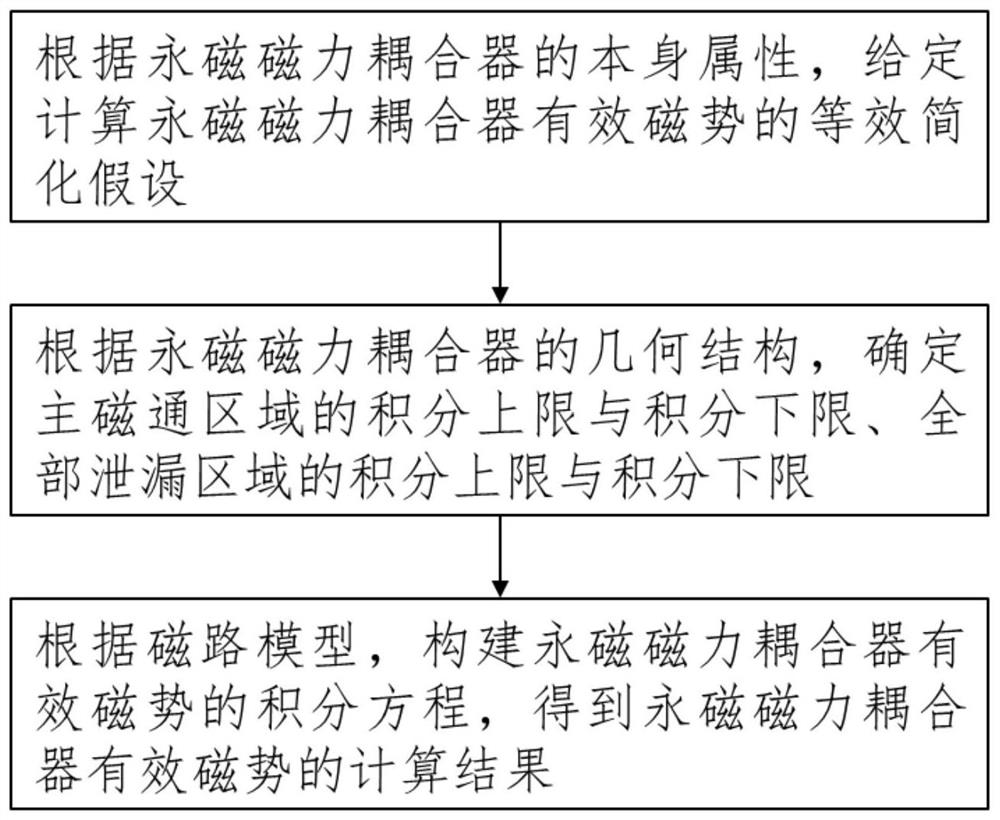

A magnetic coupling and calculation method technology, applied in the direction of permanent magnetic clutch/brake, electric brake/clutch, design optimization/simulation, etc., can solve the application constraints of rapid optimization, and the effective magnetic potential of permanent magnetic coupling cannot be quantified Given calculation results, long calculation time and other problems, to achieve rapid and accurate calculation and prediction, simple and effective calculation method, and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and technical solutions.

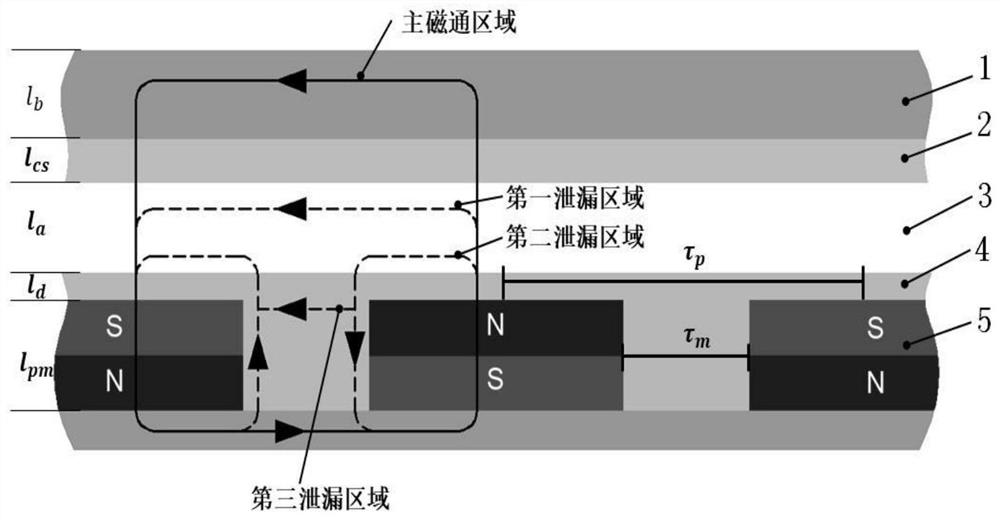

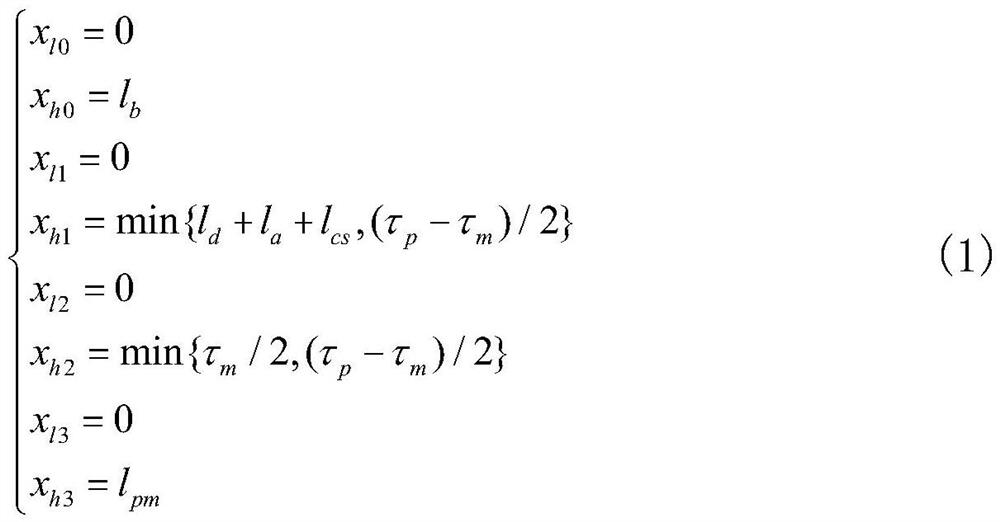

[0040] In this embodiment, the transmission torque of a permanent magnet magnetic coupling with an input speed of 1500 r / min and a single-disc structure with 6 magnetic pole pairs is selected for calculation. Among them, the basic size of the permanent magnet magnetic coupler with an input speed of 1500r / min and a single-disc structure with 6 pole pairs is: the magnetic induction of the permanent magnet H pm =890×10 3 A / m, permanent magnet thickness l pm =25mm, permanent magnet width w pm =50mm, conductor back iron thickness l b =10mm, vacuum permeability μ 0 =4π×10 -7 H / m, conductor rotor thickness l cs =6mm, air gap thickness l a =5mm, permanent magnet rotor thickness l d =1mm, the distance between the centers of adjacent permanent magnets τ p =78.5mm, distance between adjacent permanent magnets τ m =28.5mm

[0041] attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com