Intelligent machining bed for intelligent manufacturing industry and machining process

A manufacturing and intelligent technology, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of slow manual feeding efficiency and inaccurate control of the ratio, achieving high collection efficiency and solving problems. Technical problems, accurate proportioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

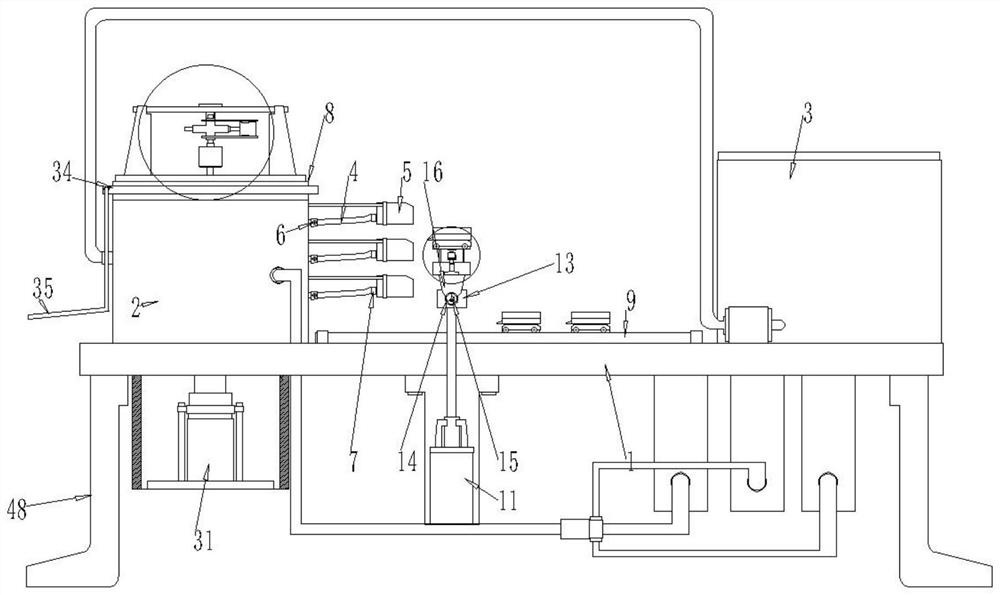

[0041] The technical solution provides an intelligent processing bed for intelligent manufacturing, including a machine base 1, a mixing tank 2, a material collection tank 3, a number of liquid storage tanks and a number of powder storage tanks, characterized in that the mixing tank 2 Set on the machine base 1, the material collection tank 3 is located on the machine base 1, and is located on the side of the mixing tank 2, and communicated with the mixing tank 2, and several liquid storage tanks are located inside the machine base 1, and communicated with the mixing tank 2, several The powder storage tank is set on the top of the base 1 through a lifting structure, and is located on one side of the mixing tank 2. The outer wall of the mixing tank 2 is provided with a number of intake pipes 4 from top to bottom, and the other end of the intake tube 4 is connected to a storage chamber 5. The pipe 4 is provided with a solenoid valve 6 and a flow control valve 7;

[0042] The end ...

Embodiment 2

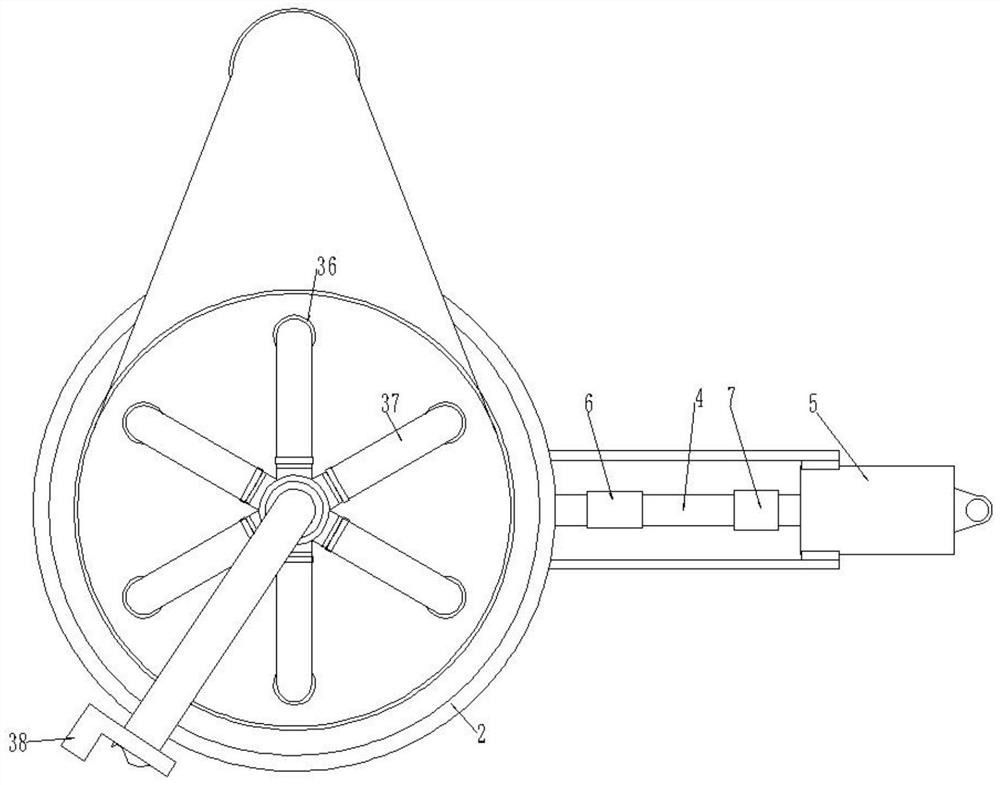

[0046] The lifting structure includes: a pair of slide rails 9, a number of sliding body components, a lifting platform 10, a main electric push rod 11, an auxiliary electric push rod 12, a turret 13, a rotating motor 14, a rotating shaft 15, a connecting frame 16, a motor 17, Locking bar 18, several groups of positioning pin rods 19;

[0047] A pair of slide rails 9 is laid on the machine base 1, several slide body assemblies are arranged on the pair of slide rails 9 in sequence, the powder storage tank is arranged on the slide body assembly, the main electric push rod 11 is arranged inside the machine base 1, Frame 13 is connected with the telescoping end of main electric push rod 11, and rotating motor 14 is arranged on the outer wall of rotating frame 13, and rotating shaft 15 is inserted on rotating frame 13, and connecting frame 16 is connected with rotating shaft 15, and rotating motor 14 and The rotating shaft 15 is connected, the lifting table 10 is embedded on the tu...

Embodiment 3

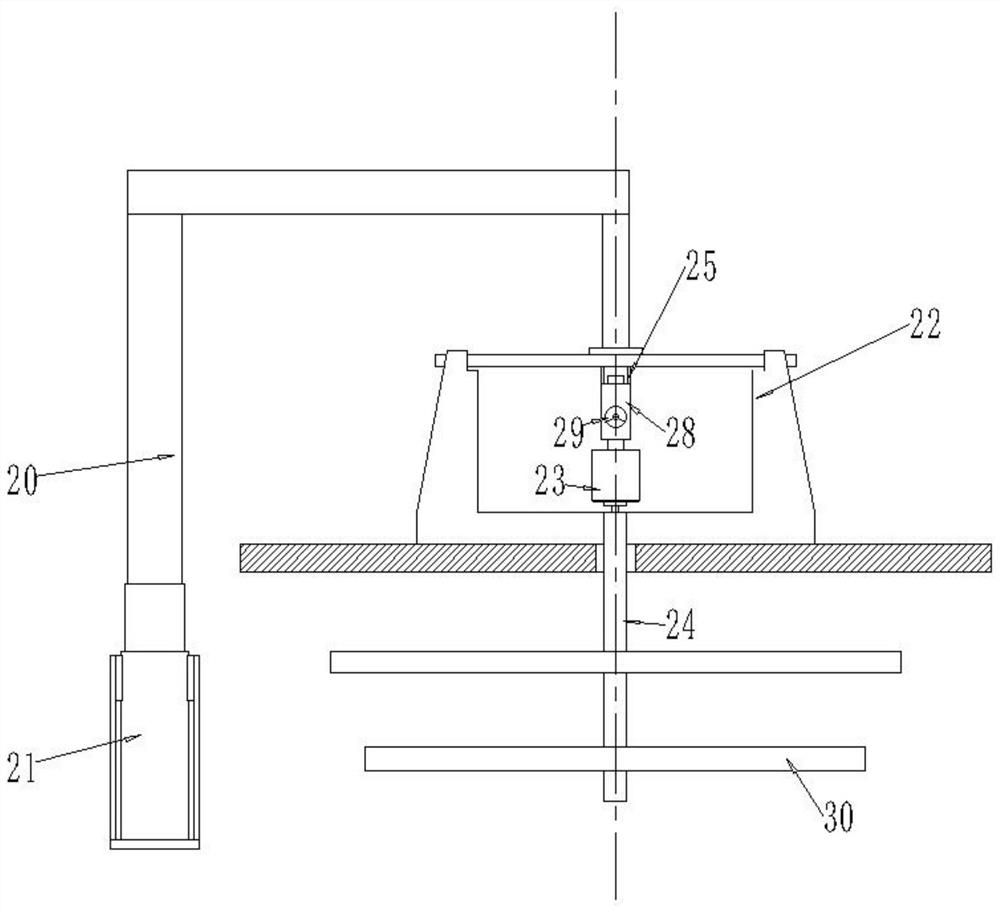

[0050] The stirring structure includes lifting rod 20, hydraulic cylinder 21, connector 22, stirring motor 23, stirring shaft 24, lifting frame 25, main screw 26, auxiliary screw 27, meshing box 28, screw motor 29 and stirring blade 30;

[0051] The hydraulic cylinder 21 is arranged on the machine base 1, the lifting rod 20 is connected with the piston end of the hydraulic cylinder 21, the end cover 8 is fixed with one end of the lifting rod 20 through the connecting piece 22, and the lifting frame 25 is arranged on the end cover 8, engaging The box is located at the center of the lift, the main screw 26 and the auxiliary screw 27 cross through the meshing box and mesh with each other, the auxiliary screw 27 can extend into the mixing tank 2, the end of the auxiliary screw 27 is connected with the lifting frame 25, the auxiliary screw 27 is connected to the stirring motor 23 after penetrating the bottom of the end cover 8, the stirring shaft 24 is connected to the driving end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com