Polymer water-based paint manufacturing process

A water-based paint and manufacturing process technology, applied in the field of paint, can solve the problems of reducing the dispersion uniformity of raw materials, the limited rotation range of the stirring rod, and shortening the service life, etc., so as to expand the range of relative motion, expand the range of relative motion, and improve the uniformity of mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

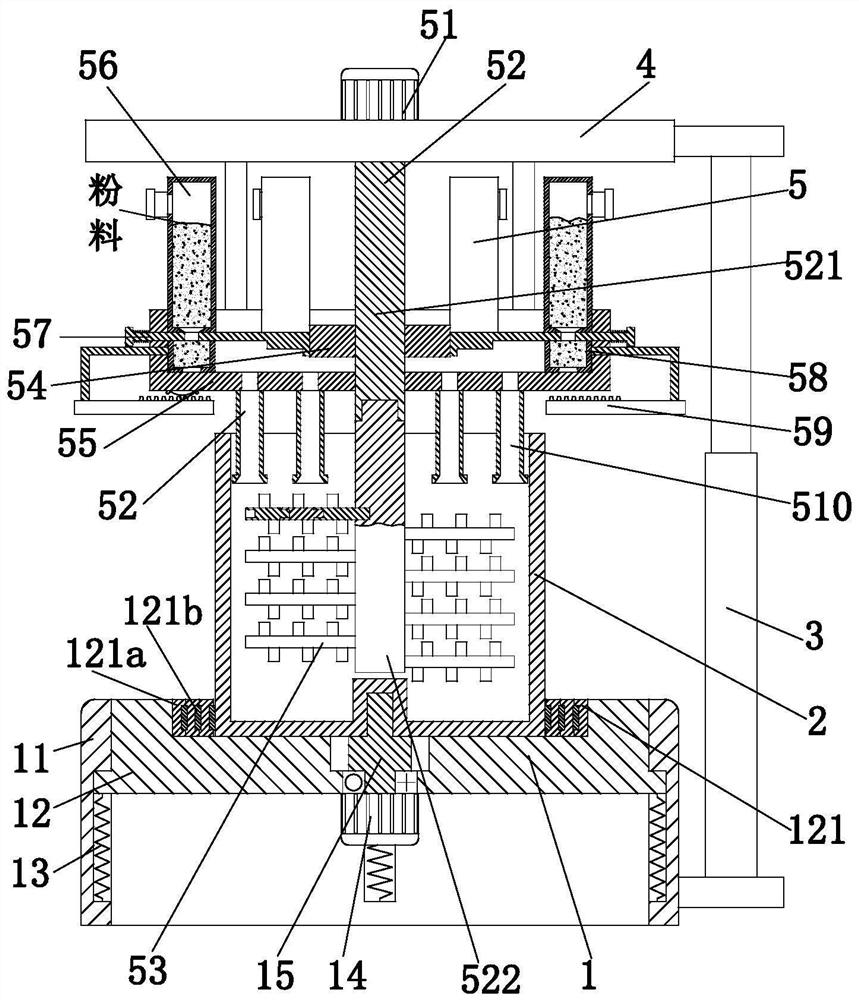

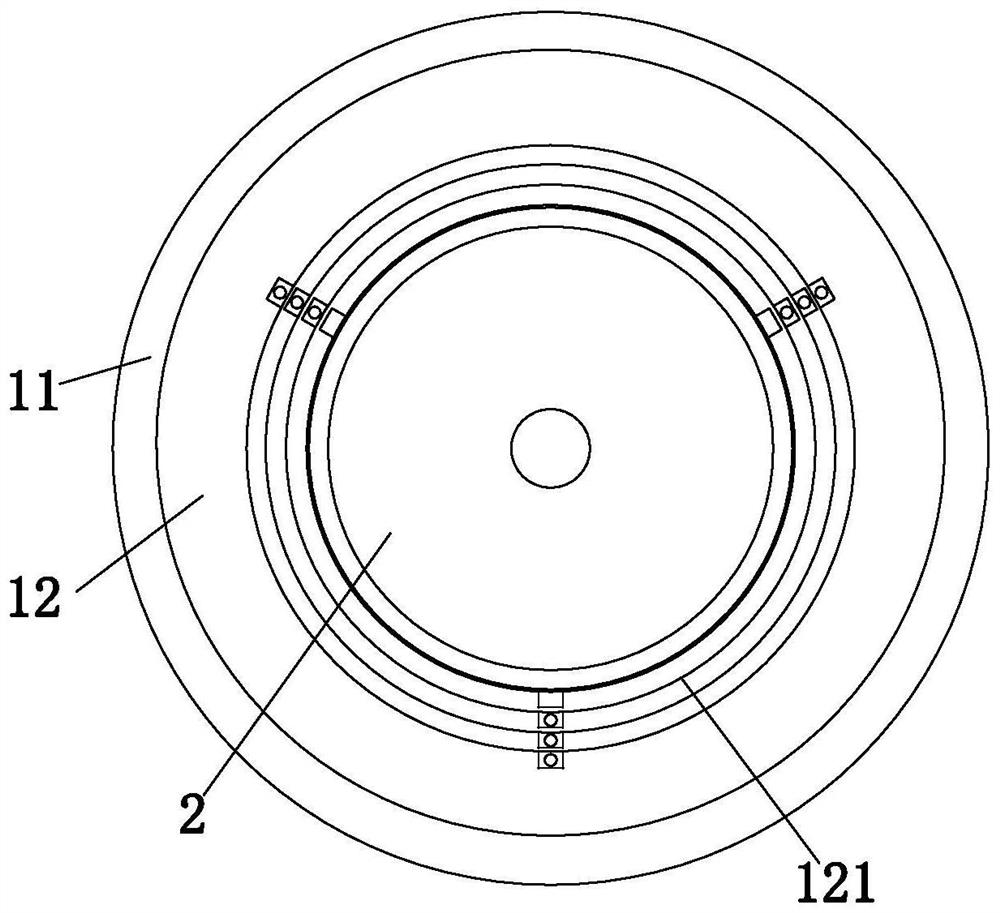

[0035] Such as Figure 1 to Figure 6 As shown, a polymer water-based paint production process uses a raw material dispersing equipment, the raw material dispersing equipment includes a supporting seat 1, a raw material barrel 2, a lifting cylinder 3, a top plate 4 and a dispersing device 5, and a supporting seat 1 A raw material barrel 2 is placed on the upper end, and a dispersing device 5 is arranged on the upper end of the raw material barrel 2. The dispersing device 5 is installed on the top plate 4, and a lifting cylinder 3 is installed between the top plate 4 and the supporting seat 1. Groove, the specific method when using the above-mentioned raw material dispersion equipment to make polymer water-based paint is as follows:

[0036] S1. Raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com