Additive Manufacturing Technology and Equipment of Rolling Composite Selective Laser Melting

A selective laser melting and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problem of high porosity, and achieve the effects of reducing porosity, inhibiting the formation of microcracks, and refining the microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The additive manufacturing process of rolling-rolling composite selective laser melting includes the following steps:

[0035] S1. Import the 3D model of the parts to be processed into the process planning and slicing software, and then perform model pre-processing such as model restoration and adding supports; then set the process parameters, including powder spreading parameters, rolling parameters, laser parameters and environmental parameters; Rolling parameters include rolling speed, rolling reduction and rolling times; finally, slicing is performed to obtain processing files;

[0036] S2. The forming platform moves to the Z-axis origin of the platform; the processing file is imported into the industrial computer of the additive manufacturing equipment, and the control software in the industrial computer reads the processing file, and then controls the powder feeding device, powder spreading device, laser system, and rolling The device and the forming platform move...

Embodiment 2

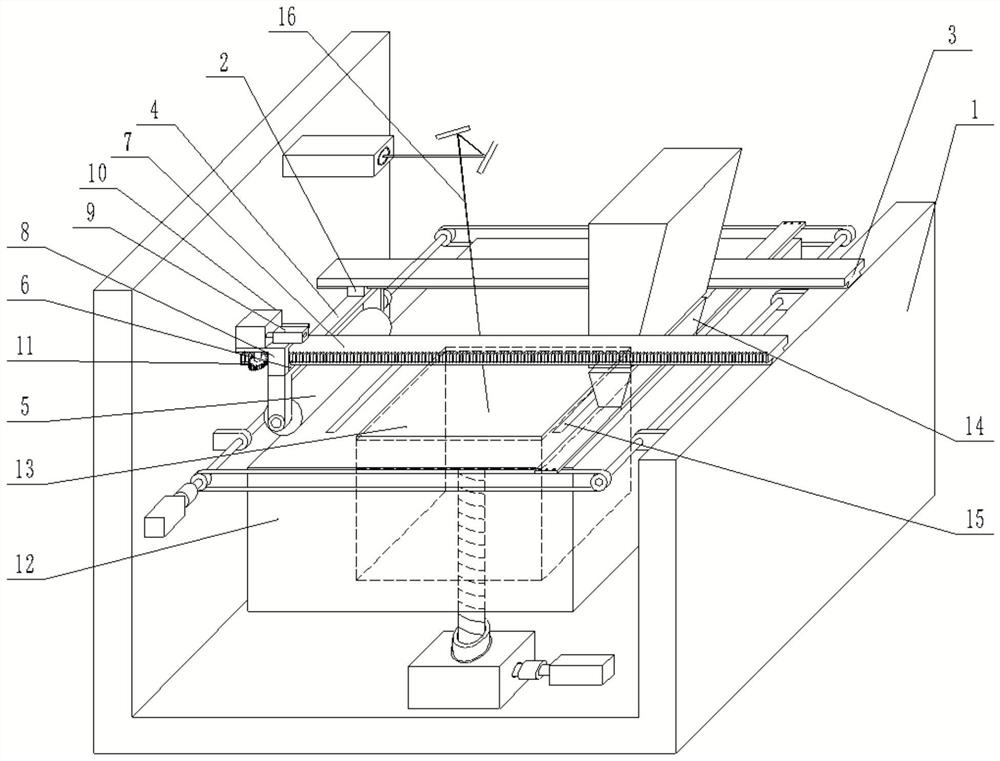

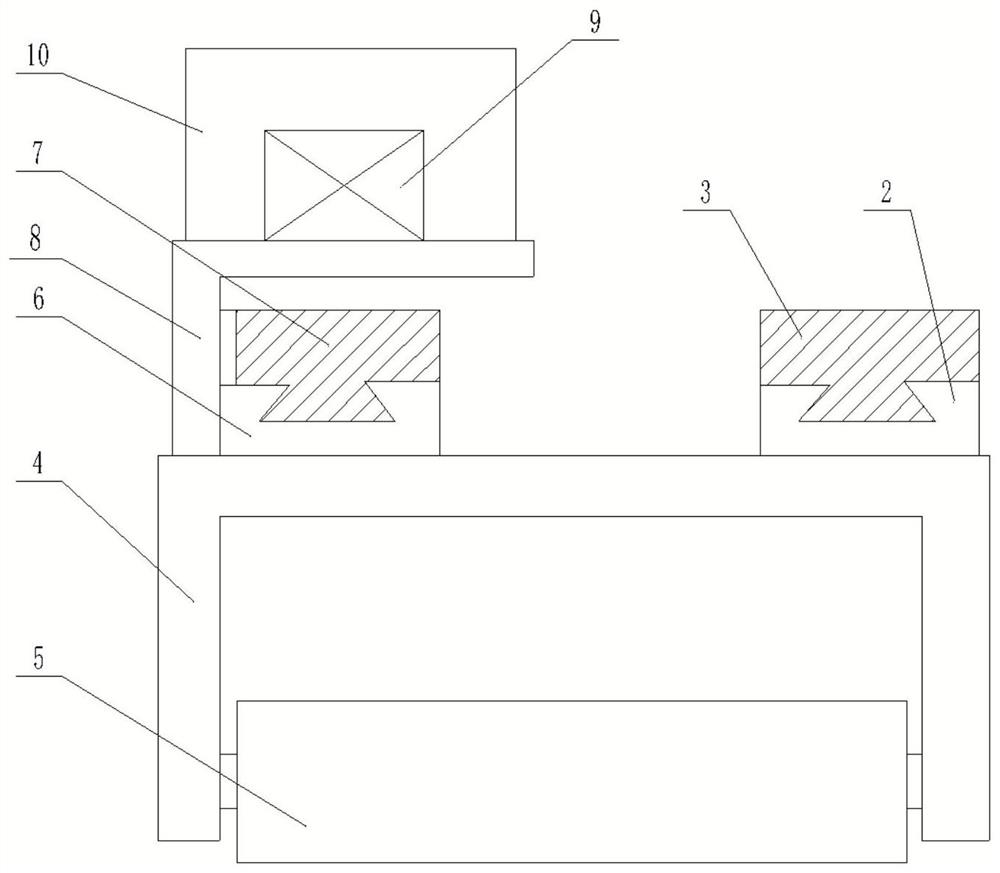

[0047] Such as Figure 1-2As shown, a kind of additive manufacturing equipment for rolling compound selective laser melting includes a frame 1, a forming cylinder 12, a forming platform 13 and a powder spreading device 14, and the forming platform 13 can slide up and down in the forming cylinder 12. It is characterized in that : also comprise rolling device; Rolling device comprises support frame 4, roll 5, the first dovetail slider 6, the first dovetail guide rail 7, motor 9, speed reducer 10 and gear 11; The section of support frame 4 is inverted " U ” shape; the opening of the support frame 4 is hinged with a roll 5; the roll 5 is in contact with the upper surface of the forming cylinder 12; the upper surface of the support frame 4 is fixedly connected with the first dovetail slider 6; The guide rail 7 is slidingly fitted; the first dovetail guide rail 7 is fixedly connected with the frame 1; the side wall of the first dovetail guide rail 7 is processed with a tooth shape; ...

Embodiment 3

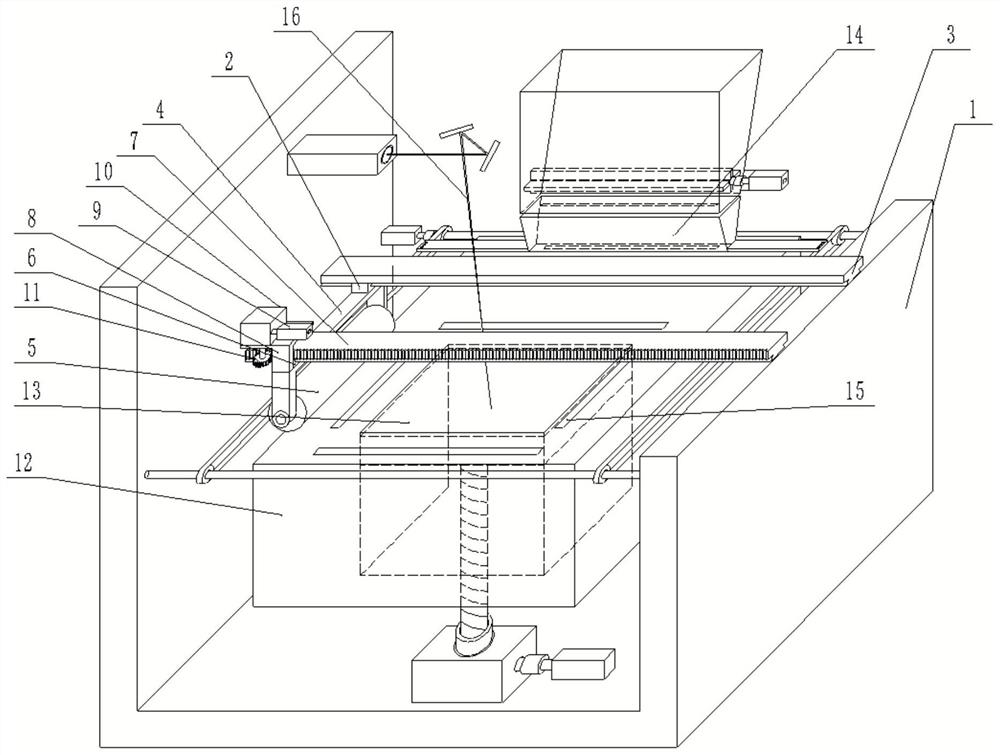

[0051] Such as image 3 As shown, a kind of additive manufacturing equipment for rolling compound selective laser melting includes a frame 1, a forming cylinder 12, a forming platform 13 and a powder spreading device 14, and the forming platform 13 can slide up and down in the forming cylinder 12. It is characterized in that : also comprise rolling device; Rolling device comprises support frame 4, roll 5, the first dovetail slider 6, the first dovetail guide rail 7, motor 9, speed reducer 10 and gear 11; The section of support frame 4 is inverted " U ” shape; the opening of the support frame 4 is hinged with a roll 5; the roll 5 is in contact with the upper surface of the forming cylinder 12; the upper surface of the support frame 4 is fixedly connected with the first dovetail slider 6; The guide rail 7 is slidingly fitted; the first dovetail guide rail 7 is fixedly connected with the frame 1; the side wall of the first dovetail guide rail 7 is processed with a tooth shape; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com