Wind power generation system with vacuum type lubrication grease filling robot

A wind power generation system and vacuum technology, applied in wind power generation, wind turbines, machines/engines, etc., can solve the problems of low utilization rate of grease, inability to apply grease, poor lubrication effect, etc., so as to improve the utilization rate and improve the Dispersion effect, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The following describes the present invention in further detail with reference to the accompanying drawings and specific embodiments, without limiting the scope of implementation of the present invention.

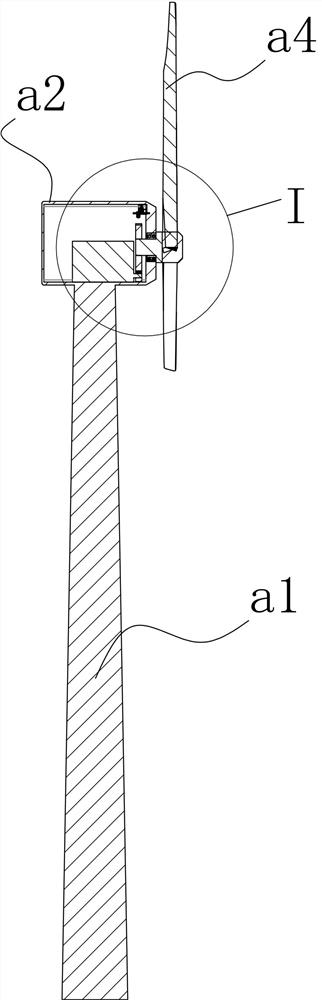

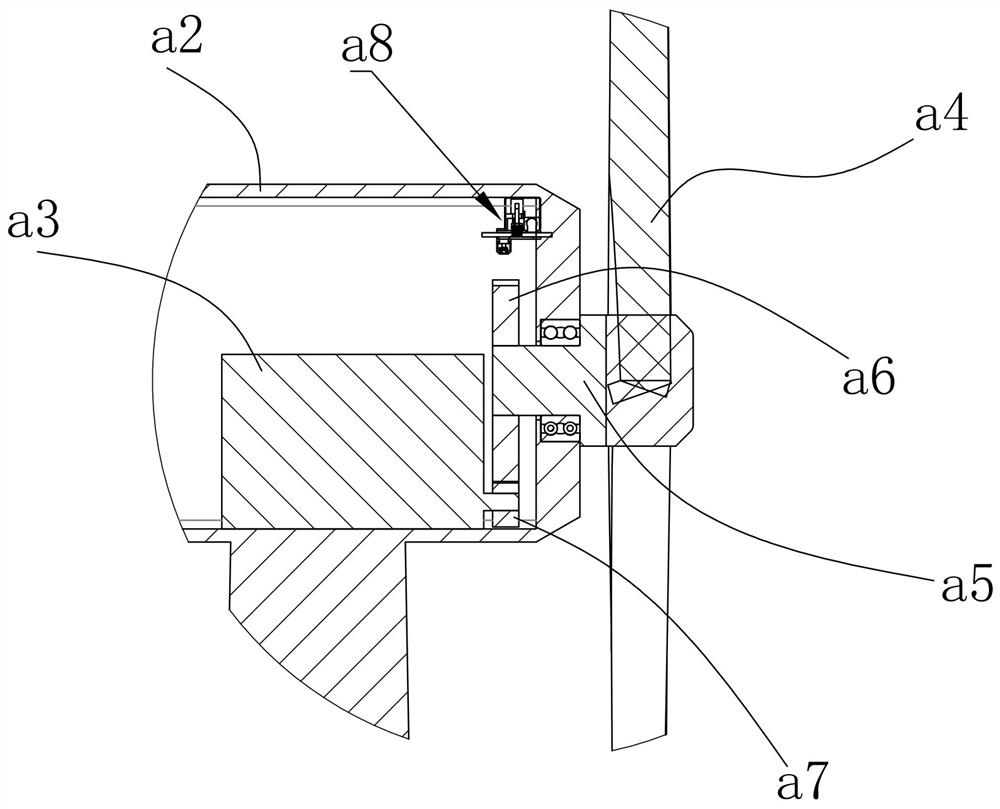

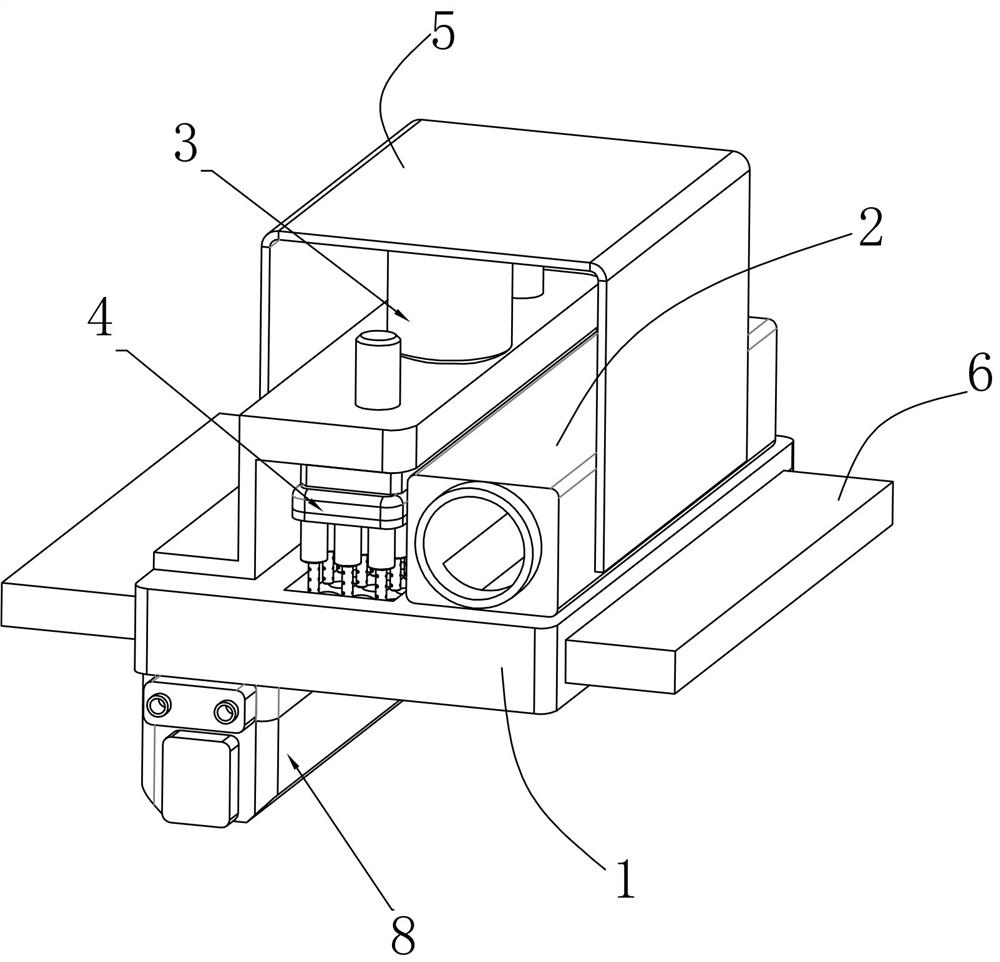

[0025]Such asFigure 1 to Figure 9As shown, the wind power generation system with its own vacuum grease filling robot in this embodiment includes a tapered column a1, a box a2, a generator a3, a blade a4, a main shaft a5, and a first gear a6 , The second gear a7 and the lubrication filling device a8; the box body a2 is integrally arranged on the top end of the tapered column a1; the generator a3 is arranged in the box body a2; the main shaft a5 is connected in rotation On one side wall of the box a2; the paddle a4 is fixed at one end of the main shaft a5, and the first gear a6 is fixedly sleeved on the other end of the main shaft a5; the second gear a7 Fixedly sleeved on the power input shaft of the generator a3 and meshed with the first gear a6, and the index circle diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com