Tricyclodecane dimethanol compositions and uses thereof

A technology of cyclodecane dimethanol and decane dimethanol, which is applied in the field of raw materials for manufacturing transparent optical materials, and can solve problems such as poor light transmittance or UV resistance, and difficult application of aromatic polyesters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] The following examples are not intended to limit the scope of the claims, but are intended to be illustrative of certain embodiments. Any variation in the exemplified methods that would occur to a person skilled in the art will fall within the scope of the invention.

[0084] The present invention is further explained by the following examples, which are only illustrative of the present invention and should not be considered as limiting the present invention in any way. The following examples are provided to better illustrate the invention and should not be construed as limiting the scope of the invention. Reference to specific materials is for purposes of illustration only and is not intended to be limiting of the invention. Those skilled in the art may develop equivalent means or reactants without exercising creativity and without departing from the scope of the present invention.

[0085] TCDDM-based composition

Embodiment 1

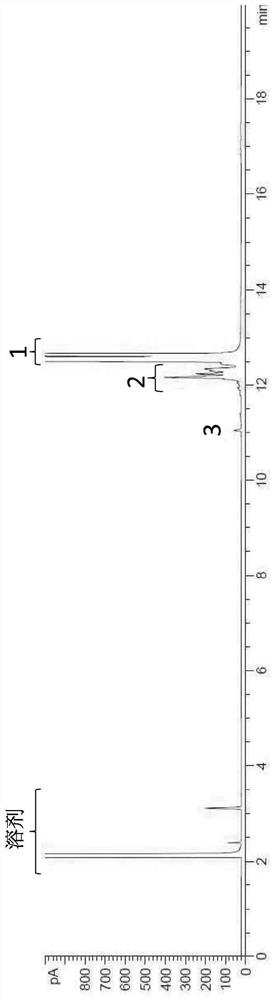

[0089] The non-aqueous hydroformylation product solution (174.5 g) obtained from the preparation example contained 2-methyl-1,3-propanediol (MPO), methanol and water in a weight ratio of 1:7:2 (MPO:methanol: Water) and aqueous extraction solvent were mixed at a mass ratio of 1:1 (non-aqueous hydroformylation product solution: aqueous extraction solvent), and stirred in a mixer whose temperature was kept at 25°C. After stirring for 1 hour, the mixture was poured into a glass extractor and allowed to stand for 2 hours to obtain a biphasic mixture (non-aqueous hydroformylation solvent layer (i.e., non-polar phase) and aqueous extraction solvent layer (i.e., polar phase). phase). The extraction temperature was maintained at 25°C. After that, 0.5g of Ni / Al 2 o 3 100 g of the aqueous phase extraction layer was added, and a hydrogen pressure of 5 MPa was introduced to carry out a hydrogenation reaction at a temperature of 60° C. for about 3 hours. Afterwards, the hydrogenated produ...

Embodiment 2

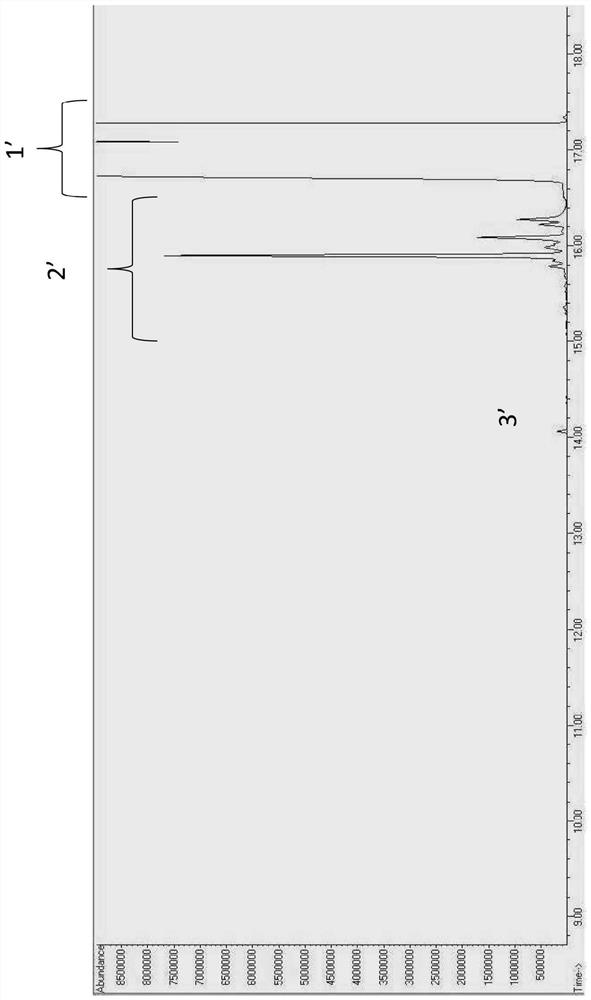

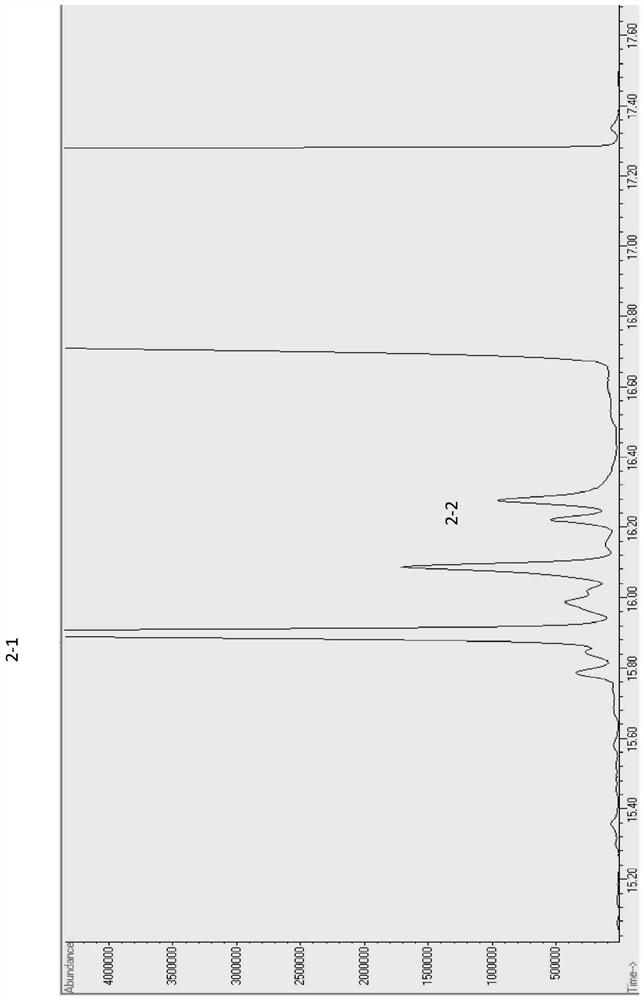

[0091] Obtained from the non-aqueous hydroformylation product solution (174.5g) of preparation example and containing tricyclic [5.2.1.0 (2,6)] decane dimethanol, methanol and water and weight ratio 1:7:2 (tricyclic [5.2.1.0 (2,6)] The aqueous extraction solvent of decane dimethanol:methanol:water) is mixed at a mass ratio of 1:1 (non-aqueous hydroformylation product solution: aqueous extraction solvent), and kept at temperature Stir in a mixer at 35°C. After stirring for 1 hour, the mixture was poured into a glass extractor and allowed to stand for 2 hours, resulting in a biphasic mixture. The extraction temperature was maintained at 35°C. After that, 0.5g of Ni / Al 2 o 3 100 g of the aqueous phase extraction layer was added, and a hydrogen pressure of 8 MPa was introduced to carry out a hydrogenation reaction at a temperature of 80° C. for about 3 hours. Afterwards, the hydrogenated product (252.4 g) was distilled at a pressure of 10 hPa in a Kirschner distillation head w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com