Preparation method of dienogest

A technology for dienogest and compounds, which is applied in the field of preparation of dienogest, can solve the problems of dark color and low purity of crude products, and achieves the effects of cheap and easy-to-obtain raw materials and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

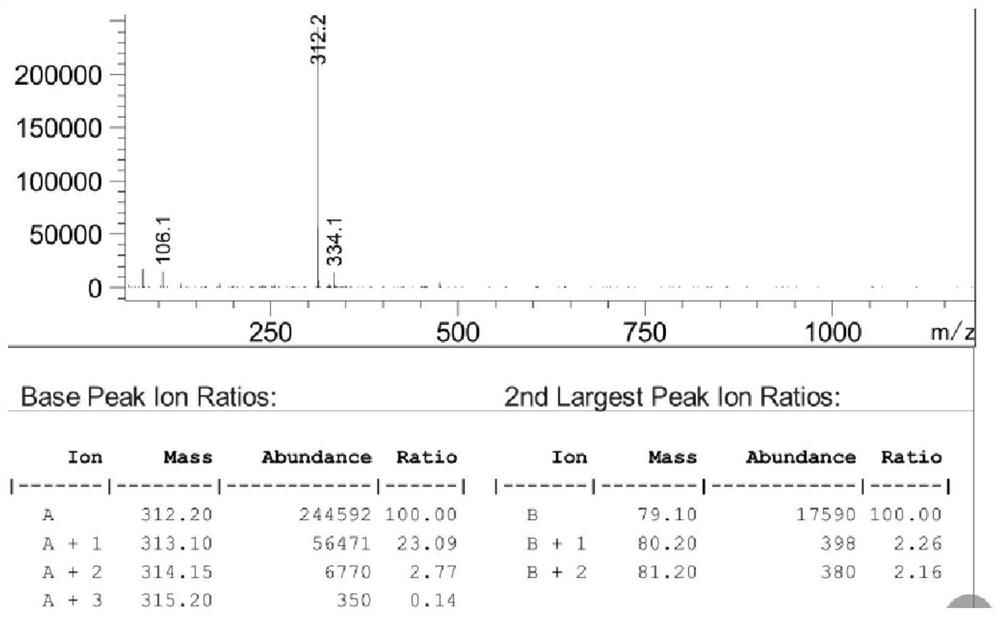

Image

Examples

preparation example Construction

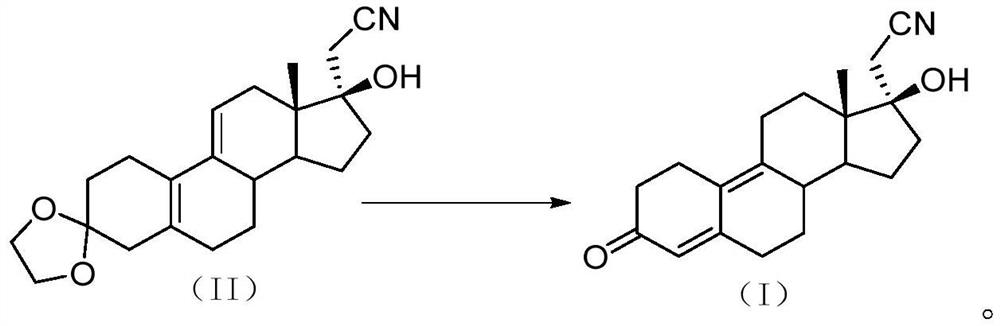

[0036] One embodiment of the present invention provides a method for preparing dienogest, comprising the following steps:

[0037] S101: providing a compound of the structure shown in formula (II);

[0038]

[0039] Can adopt existing method to prepare the compound shown in formula (II), do not carry out special limitation here, should be understood as all within the scope of protection of the present invention, preferably adopt following method to make the compound shown in structure of formula (II):

[0040] S1011: providing a compound represented by formula (III);

[0041]

[0042] Existing methods can be used to prepare the compound represented by formula (III), which is not particularly limited here, and should be understood as being within the protection scope of the present invention.

[0043] S1012: reacting the compound represented by the formula (III) with lithium cyanide to prepare the compound with the structure represented by the formula (II);

[0044] ...

Embodiment 1

[0080] (1) Preparation of the compound shown in formula (II), i.e. 17α-cyanomethyl-17β-hydroxyl-5,9-androstadiene-3,17-dione-3,3-ethylene ketal

[0081]

[0082] In the reaction flask, add 120ml of 2.5mol / L n-butyllithium, lower the temperature to below -50°C, add 240ml of tetrahydrofuran, continue to cool down to below -50°C, and start to drop the mixed solution of acetonitrile and tetrahydrofuran (8.0g / 20ml ), the dropwise addition was completed, stirred for 5 minutes, and 17β-hydroxyl-5,9-androstadiene-3,7-dione-3,3-ethylene ketal was added dropwise (source: Hunan Xinhe Xinbio Pharmaceutical Co., Ltd., purity ≥ 99.30%, mono-hetero<0.10%) tetrahydrofuran solution (30g / 100ml), dropwise, temperature control -50 ℃ ~ -90 ℃ for 30 minutes, the reaction is complete, drop dilute hydrochloric acid to terminate the reaction, separate layer, and the organic phase was concentrated under reduced pressure to a pale yellow oil with a weight of 32 g, a yield of 106%, and a purity of 98....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com