Construction method of a prefabricated steel structure building

A construction method and technology for building construction, applied in building construction, infrastructure engineering, architecture, etc., can solve the problems of large thermal energy loss, complex use requirements, complex construction, and unsatisfactory related functions, so as to reduce thermal energy loss and increase The effect of energy supply methods and building use functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

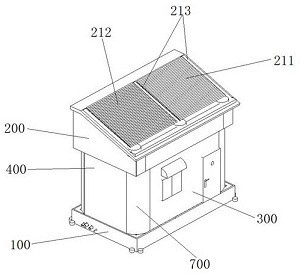

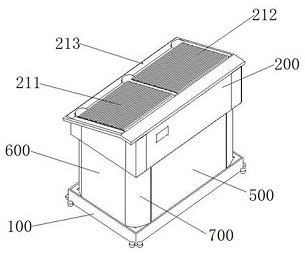

[0058] see Figure 1-Figure 19 , the present invention provides a technical solution: a prefabricated steel structure building includes a building foundation 100, four walls set on the building foundation 100, and a roof 200 set on the top of the wall, between two adjacent walls There is a corner positioning wall 700 between them, and the four walls include at least one door and window integrated wall 300, at least one pipeline integrated wall 400, at least one information energy control integrated wall 500 and at most one ordinary wall 600;

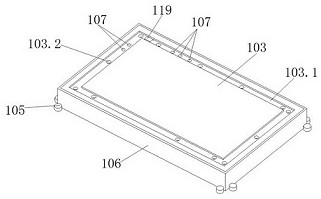

[0059] The building foundation 100 includes a rectangular basic steel frame 101, the bottom of the basic steel frame 101 is provided with a counterweight pad 102, and the top of the basic steel frame 101 is provided with a building floor 103, and the basic steel frame 101 The inner wall of the inner wall is welded with a plurality of vertically arranged basic wall fixing sleeves 104 along its perimeter direction, and the four corners of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com