Lithium ion battery repeating unit, lithium ion battery, using method of lithium ion battery, battery module and automobile

A lithium-ion battery, repeating unit technology, applied in the direction of secondary battery charging/discharging, battery pack components, non-aqueous electrolyte battery electrodes, etc., can solve safety problems, low battery energy density and other problems, achieve energy improvement, overcome Poor rate performance, the effect of overcoming the risk of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0073] In a specific embodiment, the metal body with surface pores may have micropores. For example, in one embodiment, the metal body with surface pores may have two main surfaces perpendicular to the stacking direction, wherein at least one of the main surfaces may be formed There are micropores. Among them, micropores of a certain depth can be formed on the non-porous base metal by methods such as in-situ generation, chemical and physical deposition, and corrosion formation, so as to obtain a metal body with surface pores. For example, use micron copper or copper alloy foil, and use physical vapor deposition (PVD) or chemical vapor deposition (CVD) to deposit a certain thickness of porous metal copper or carbon on the two sides of the foil; or, micron copper or copper The alloy foil is placed in an acidic or alkaline chemical corrosion solution and corroded for a certain period of time to form corrosion holes on both sides.

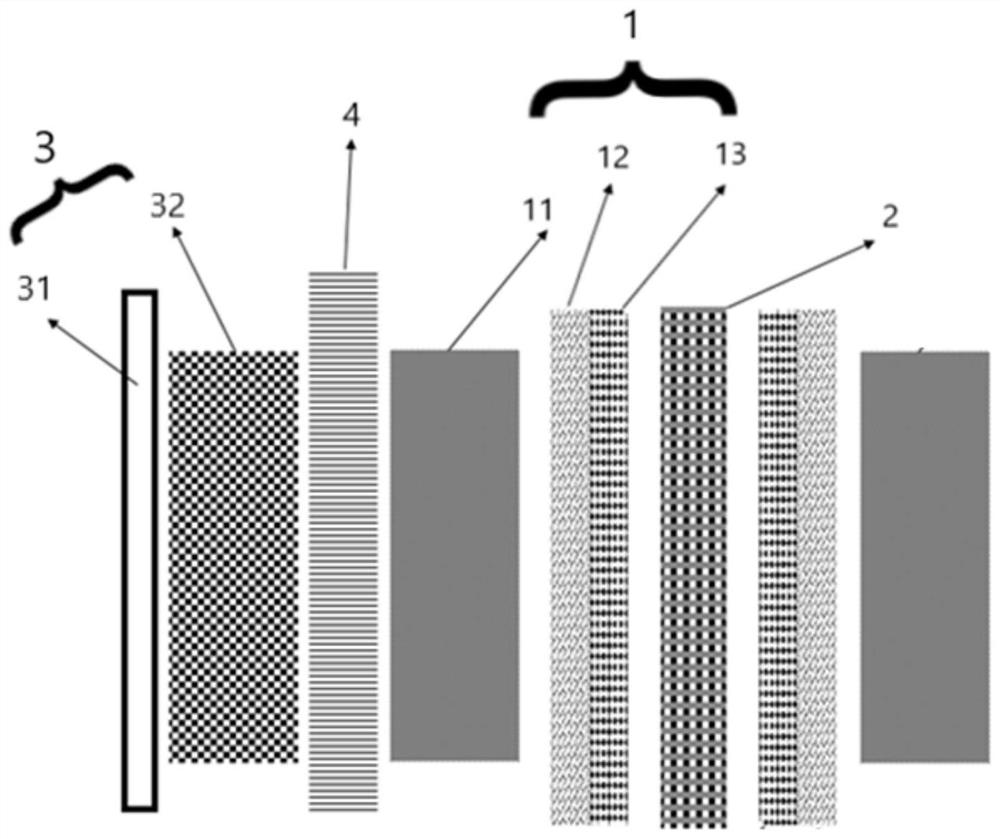

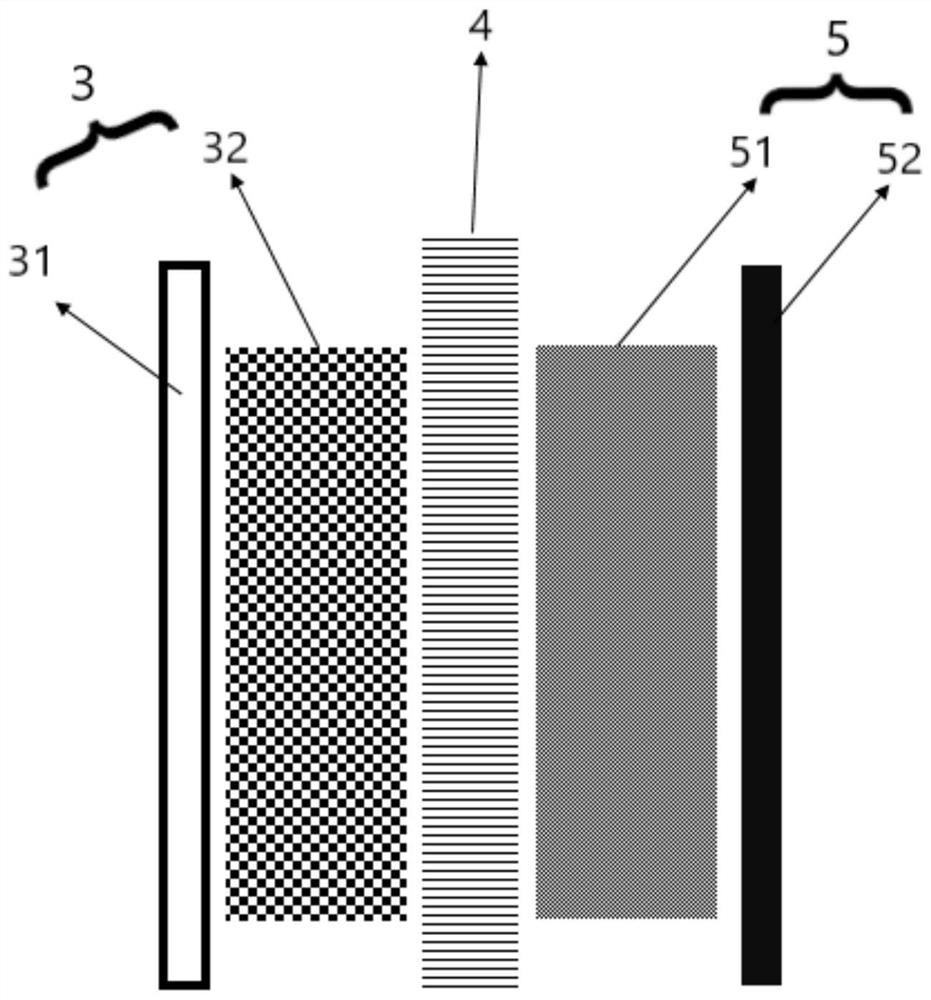

[0074] In another preferred embodiment, refer t...

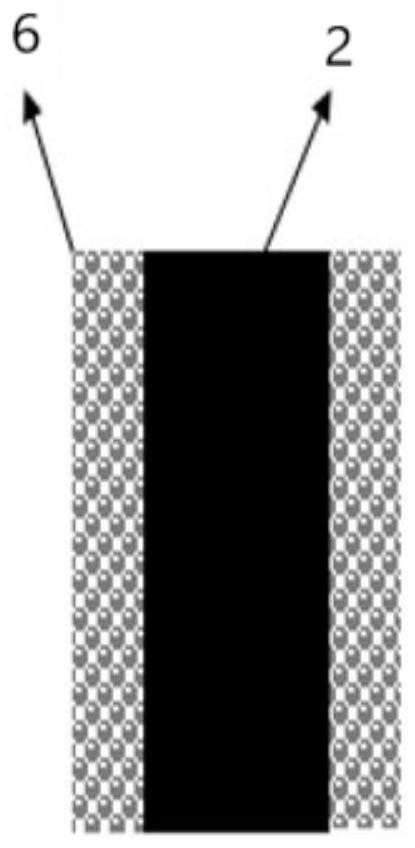

Embodiment approach

[0075] Further, the solid metal part 22 may be a solid metal body (such as metal foil, metal sheet, metal cloth, etc.). The thickness of the solid metal part 22 may be 1-50 μm, preferably 5-15 μm. The first porous part 21 and the second porous part 23 can be respectively porous metal material, porous carbon material or porous oxide material, such as copper mesh or copper foam. The thicknesses of the first porous portion 21 and the second porous portion 23 may each be 1 to 50 μm, preferably 5 to 15 μm. In this embodiment, the first porous part 21, the solid metal part 22 and the second porous part 23 can be stacked in sequence and then connected into a whole through physical pressing, or bonded and fired into a whole, so as to obtain a Porous metal body. For example, in one embodiment, copper mesh (or copper foam), copper foil, and copper mesh (or copper foam) can be welded together with superimposed current in sequence to obtain a metal body with surface pores.

[0076] Fur...

Embodiment 1

[0096] 1. Preparation of positive electrode: Weigh the positive active material (LiCoO 2 ) 1kg, conductive agent carbon nanotube 20g and binding agent polyvinylidene fluoride (PVDF) 20g join in the N-methylpyrrolidone of 1kg, then stir 30min in the stirrer, form stable and uniform slurry; The slurry Coat evenly on aluminum foil, transfer to an oven to dry at 80°C; press the dried pole pieces under 2MPa pressure, cut them into 50mm×75mm pole pieces, and spot-weld the positive lugs, surface density 30mg / cm 2 .

[0097] 2. Preparation of the separator: take a common commercial 11 μm PVDF-coated lithium battery PE separator and cut it into 77 mm wide.

[0098] 3. Preparation of the first negative electrode: take a common commercial 11 μm PVDF-coated lithium battery PE separator (insulating layer), and hot-press it with a 20 μm thick copper mesh (conductor layer) at 120 ° C for 30 seconds at a pressure of 1 MPa. The copper mesh porosity is 50%, the aperture is 1mm. Weigh 1 kg o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com