Cooking method of food processing device

A technology of food processing device and cooking method, which is applied in household appliances, applications, kitchen utensils, etc., can solve the problems of slurry splashing, and achieve the effects of avoiding slurry overflow, reducing the risk of slurry overflow, and avoiding slurry splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to explain the overall concept of the present application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

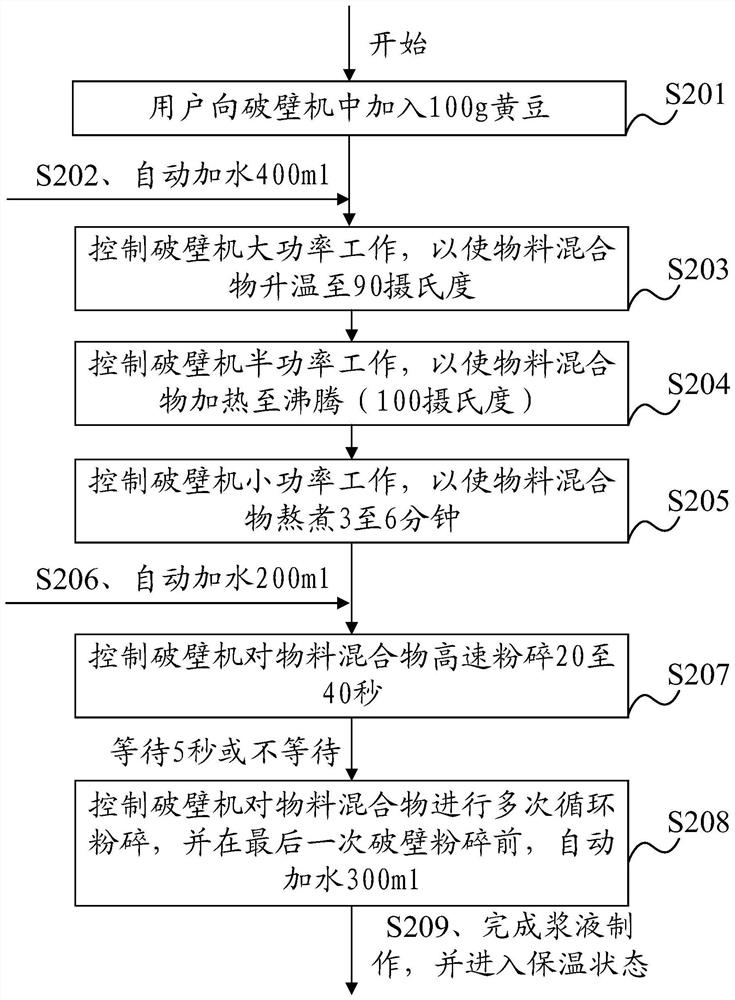

[0039] In the embodiment of the present application, the technical problems existing in the prior art are effectively solved by adding the amount of water required to be added during the cooking process in multiple times at the right time. It should be noted that, either according to user needs or in order to achieve a better cooking effect, the sum of the actual amount of water added in multiple times can be appropriately adjusted so as to be the same as the required amount of water as much as possible.

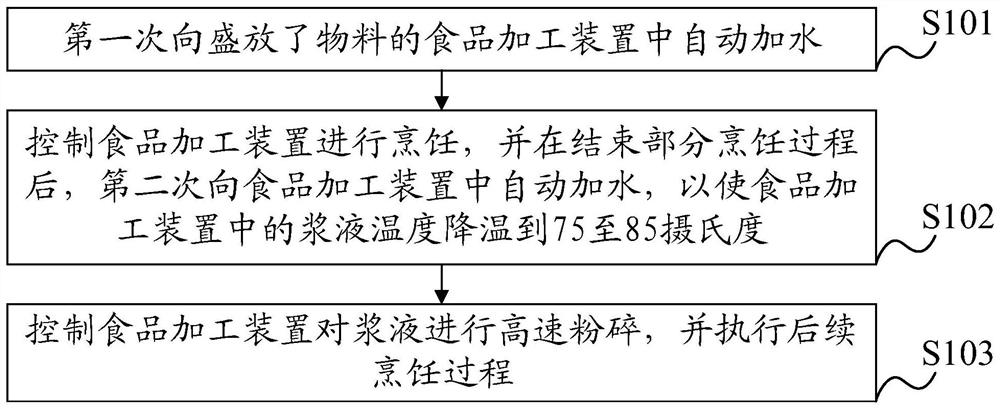

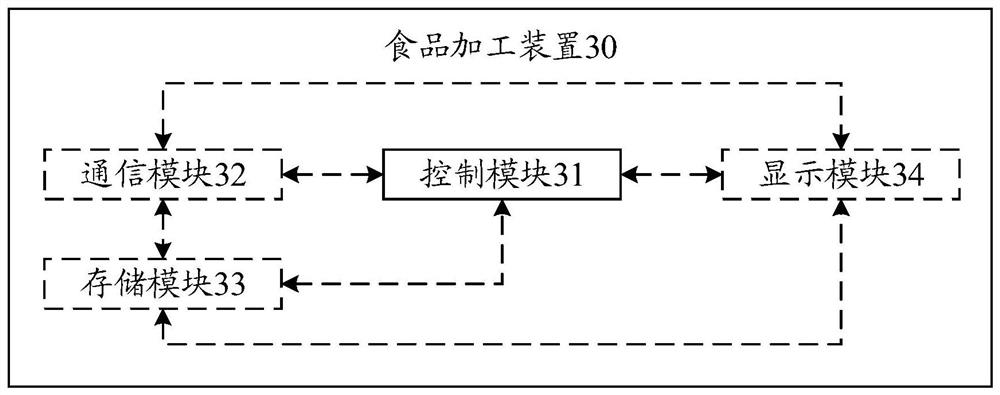

[0040] An embodiment of the present application provides a cooking method for a food processing device. The method can be applied to food processing devices that involve crushing, boiling and / or stirring material mixtures, such as wall breakers and soybean milk makers. Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com