A kind of metal base flat grinding block material for concrete grinding

A technology of concrete and grinding blocks, which is applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of poor versatility and material cost increase, and achieve the effect of improving product cost performance, high cost performance, and increased utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

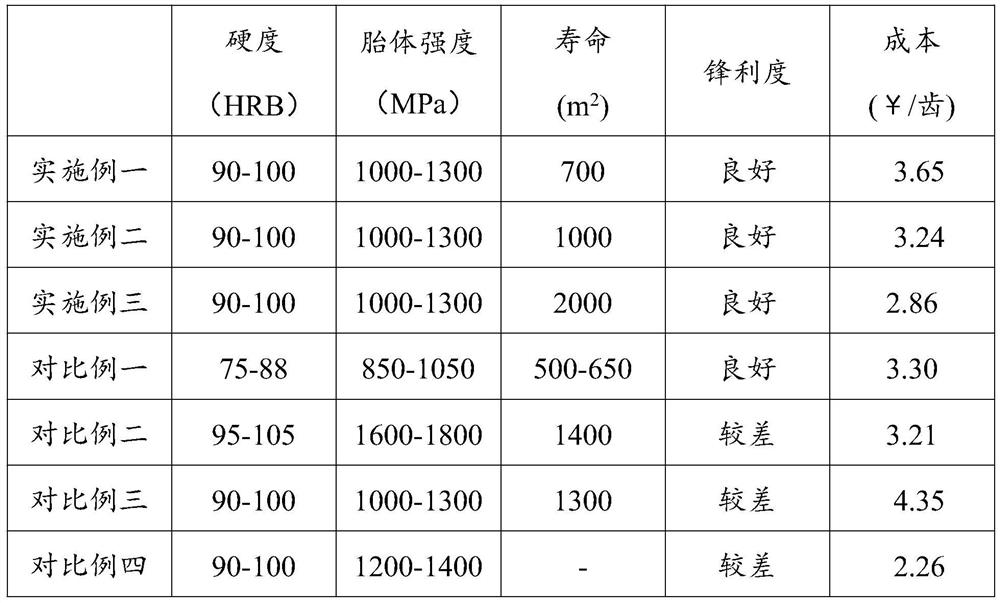

Embodiment 1

[0035] A metal-based floor grinding block material for concrete grinding, the components and mass percentages of which are as follows:

[0036] Abrasives: 25#-40# diamond, 30%; system materials, Fe, 60%, Cu, 7%, Ni, 1.2%, Sn, 0.8%; weakening materials include: aluminum-silicon pre-alloyed powder (Si content is 12.6 %),1%.

[0037] The performance of the metal-based grinding block material prepared by using the above ratio: the hardness is 90-100HRB, the strength is 1000-1300MPa, the sharpness is good in the process of grinding the ground, the energy consumption is low, and the grinding life can reach 700m 2 above.

Embodiment 2

[0039] A metal-based floor grinding block material for concrete grinding, the components and mass percentages of which are as follows:

[0040] Abrasives: 60#-80# diamond, 20%; system materials, Fe, 68.5%, Cu, 8%, Ni, 1.5%, Sn, 1%); weakening materials include: aluminum-silicon pre-alloyed powder (Si content is 12.6%), 1%.

[0041] The performance of the metal-based grinding block material prepared by the above ratio: the hardness is 90-100HRB, the strength is 1000-1300MPa, the sharpness is good in the process of grinding the ground, the energy consumption is low, and the grinding life can reach 1000m 2 above.

Embodiment 3

[0043] A metal-based floor grinding block material for concrete grinding, the components and mass percentages of which are as follows:

[0044] The components and mass percentages of metal-based grinding block materials are as follows: Abrasive: Abrasive: 100#-120# diamond, 6%; system material, Fe, 80%, Cu, 10%, Ni, 1.8%, Sn, 1.2 %); the weakening material includes: aluminum-silicon pre-alloyed powder (Si content is 12.6%), 1%.

[0045] The metal-based grinding block material prepared by the above ratio has the following properties: the hardness is 90-100HRB, the strength is 1000-1300MPa, the sharpness is good in the process of grinding the ground, the energy consumption is low, and the grinding life can reach 2000m 2 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com